Electric Butterfly Valve

Description of Electric Butterfly Valve:

ZECO electric butterfly valve is named after electric actuator operated. Butterfly valve in the pipeline for a long time to use, may be due to special medium, temperature or pressure causes a small number of problems, encounter these problems, we must think of ways to solve, and in order to prevent, no problems of the product for regular maintenance. The leakage of stem sealing usually caused by packing abrasion,can make up for tightening the packing gland. Too large packing force may increase stem friction, and make stem to be hard operated and accelerated the abrasion of packing.

Good sealing inside valve will be affected the sealing performance because of the damage or normal abrasion. For the harsh working conditions, the estimation and repairment beyond the scope of this manual, due to a variety of different structural forms, if need to know in advance, should cooperate with the manufacturer to find a suitable method. The external construction of valve is easy to check and maintain. So rational approach should be taken to prevent mechanical to damage the valve, prevent valve corrosion by the sediments in the atmosphere、chemical substances or wet gas and deterioration of its quality. Thread、bearings or gears work like the working interface should be periodic lubrication.

Features of Electric Butterfly Valve:

Material of Electric Butterfly Valve:

|

No |

Part |

Material |

|

1 |

Body |

ASTM A216 WCB + 13Cr |

|

2 |

Seal Ring |

Graphite + SS304 |

|

3 |

Retainer Flange |

ASTM A105 |

|

4 |

Pin |

ASTM A276 410 |

|

5 |

Disc |

ASTM A216 WCB |

|

6 |

Stem |

ASTM A276 410 |

|

7 |

Stem Packing |

Graphite |

|

8 |

Stem Beating |

SS304 + PTFE |

|

9 |

Bolt |

ASTM A193 B7 |

|

10 |

Nut |

ASTM A194 2H |

|

11 |

Yoke |

ASTM A216 WCB |

Now the electric butterfly valve priceis low, if you want to buy our products,leave us a message.

ZECO Valve Group, as one of the China check valve manufacturers, founded in 1991 located in Shanghai, Yancheng, Wenzhou with focus on manufacturing through conduit gate Valve China, floating ball valve, trunnion mounted ball valve, top entry ball valve,swing check valve, dual plate check valve and forged valve.

在线联系供应商

Other supplier products

| Resilient Seated Gate Valve | Features of resilient seal gate valve Full diameter flat - bottom runner, no debris pooling; Fully covered EPDM disc, no corrosion; Movabl... | |

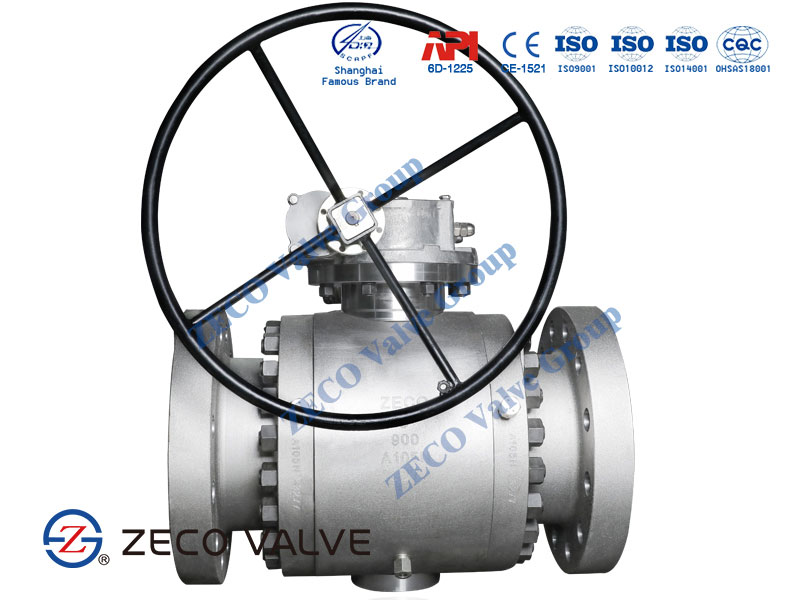

| Gear Operated Ball Valve | Description of : Large size ball valve if adopt manual operation will reduce the efficiency of personnel, even if many people help may also be beca... | |

| 6 Inch Butterfly Valve | Description of 6 Inch Butterfly Valve: ZECO provides detailed installation instructions to ensure high performance and long service life of the 6 w... | |

| 3 Inch Butterfly Valve | Description of 3 Inch Butterfly Valve: ZECO 3 inch flanged butterfly valveis a small diameter butterfly valve, usually manually operated, and the c... | |

| 3 inch Butterfly Valve | Categories: Butterfly Valve, Butterfly Valve By Inch Tags: Butterfly Valve Wafer Type, Wafer Type Butterfly Valve What is 3 Inch Wafer Type But... |

Same products

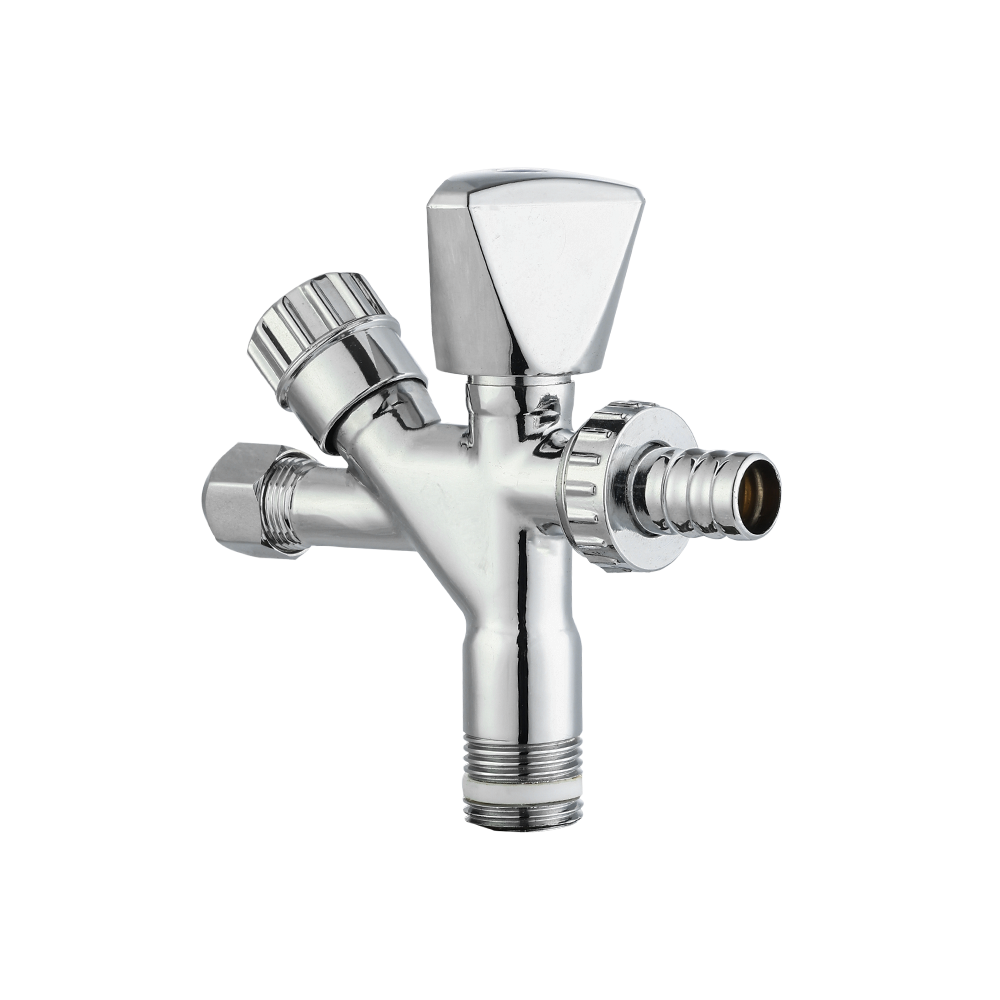

| Combination angle valve | 卖方: Zhejiang Huaqi Information Technology Co., LTD | Meet our Brass Angle Ball Valve, a versatile and reliable solution for controlling fluid flow in ... | |

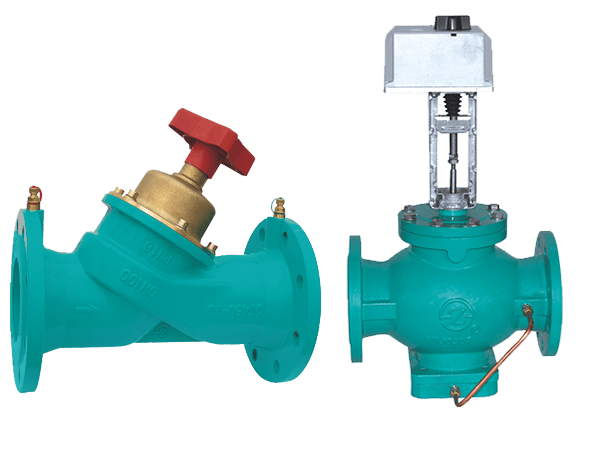

| Multifunctional hydraulic control valve | 卖方: FLUID TECH PIPING SYSTEMS (TIANJIN) CO.,LTD | Features: Size: 2"-24”(DN50-DN600) Material: Ductile iron ASTM A536, 65-45-12 Dimension:... | |

| Fire Protection Grooved Butterfly Valve | 卖方: FLUID TECH PIPING SYSTEMS (TIANJIN) CO.,LTD | Features: Code:D81X4 Size: 2"-12”(DN50-DN300) Material: Ductile iron ASTM A536, 65-45-12... | |

| Dry Ash Gate Valve | 卖方: China Valve Industry Co., Ltd. | The dry ash gate valve is designed for both inlet and outlet pipelines. It features... | |

| China factory High temperature double head bolt 2""-8UN Steam Turbine RSV N for power station | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "China factory High temperature double head bolt 2""-8UN Steam Turbine RSV N for power stationOur... |