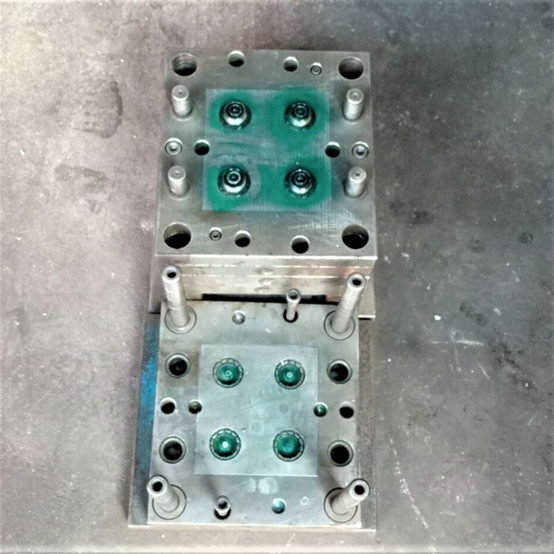

Plastic Injection Mould

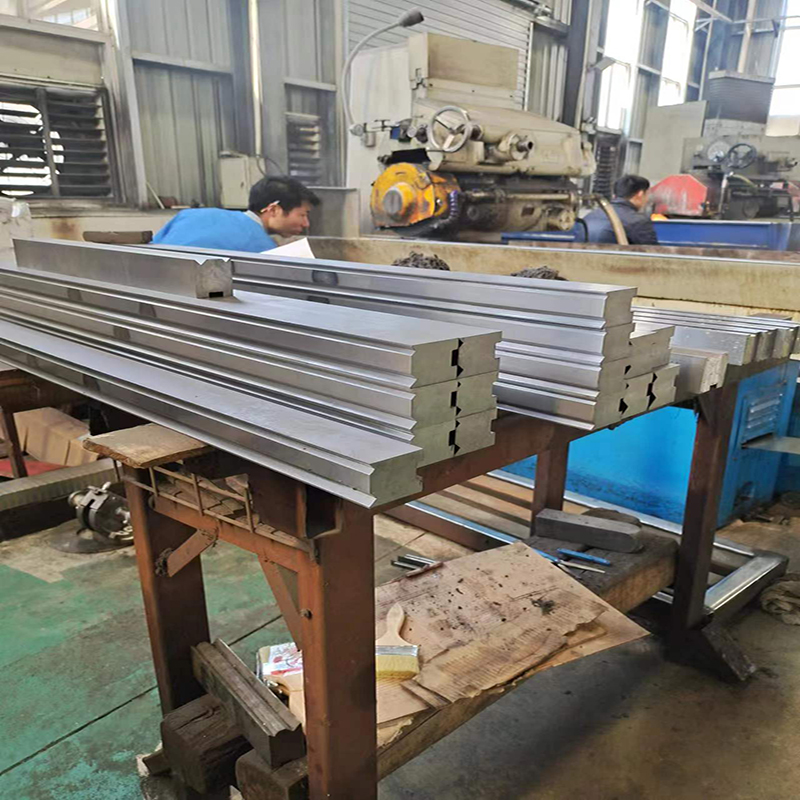

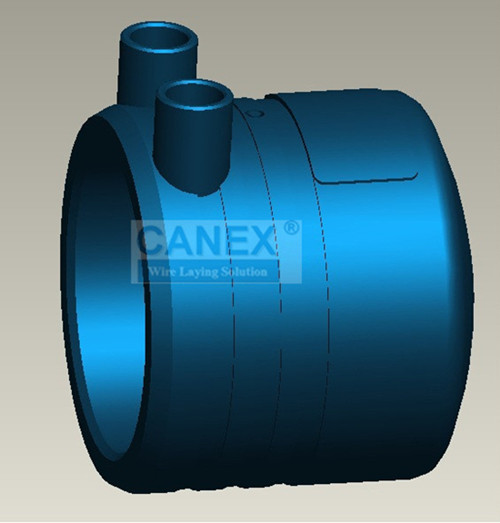

All kinds of tools and products we use in our daily life, ranging from base of machine tools and shellof fuselage to shell of a embryo head screw, buttons and various household appliances, are closely related to mould. Shape of moulddetermines shape of these products, quality and precision of mouldalso determine quality of these products. Because of different material, appearance, specifications and uses of various products, moulds are divided into casting, forging, die-casting, stamping and other non-plastic moulds, as well as plastic moulds.

In recent years, with rapid development of plastic industry,improvement of strength and precision of general purpose and engineering plastics, application scope of plastic products is also expanding. For example, household appliances, instruments, building equipment, automobile industry, daily hardware and many other fields, proportion of plastic products is increasing rapidly. A reasonably designed plastic part can often replace many traditional metal parts. Trend of plasticization of industrial and daily products is rising.Plastic moulds are a short form of combined moulds used for compression, extrusion, injection, blow moulding and low foaming moulding. A series of plastic parts with different shapes and sizes can be processed by coordinating changes of convex, concave and auxiliary forming systems.

Other supplier products

|

|

Plastic Injection Mould |

All kinds of tools and products we use in our daily life, ranging from base of machine tools and shellof fuselage to shell of a embryo head screw, ... |

供应产品

Same products