Medical Plastic Injection Molding

ISO Class 8 Clean Room

Quality Control

Low & High Volume Manufacturing

Competitive Price

Reliability and Stability

Packson moldis not totally the same as other medical molding companies. Because we are an ISO-certified medical injection molding provider. Packson had got the certification of ISO 13485:2018 and ISO 9001:2008. We've been working with healthcare and medical companies like BD, Wondfo since 2008. With over 30-40 skilled production operators working 24 hours with 3 shifts, we can handle your long-run medical plastic injectionmolding production and help your medical injection molding parts get into the market quickly. As a professional China medical silicone molding company, Packson also contributes a modest effort to the customer's projects by providing an optimized multi-cavities solution for reaching high-volume medical injection molding production. The comprehensive and automatic assembly line is also one of our "weapons" that help your project process well. It includes a mechanical arm part handling system, sonic welding, heat staking,laser-engraving, plastic package sealing, and custom packaging. Pacskon also has extensive experience of OEMs for medical contract manufacturing services.

Do you wanna get started with us now? We would be very grateful if we have the opportunity to show you our capabilities and explain to you how we can help your company achieve various goals. Contact us to discuss your details of medical plastic injection manufacturing requirements.

Why Choose Medical Plastic Injection

With the rapid development of the medical industry, more and more medical technologies and devices are widely applied in our normal life. Since medical devices made of plastics have multi-functionality and can be mixed with material like metal to make a stronger medical product, medical plastic injection molding become the preferred material for all kinds of medical molding devices that are widely used in electronic parts. Here are the superiority of medical plastic injection that professional medical plastic injection molding companies like us can offer, including:

Produced products in high volumes

Reduced weight

Increased versatility

Lower price

The medical plastic injection process has the feature of cost-efficient, high-volume production runs. If you have some specific needs for the medical plastic injection. Then we can tell you that this kind of medical plastic injection molding helps us to make plastic medical devices requiring consistency and tight tolerances. This medical plastic injection molding process is also widely applied in prototype development for medical devices used for laboratory testing.

Medical Injection Molding

Our medical plastic injection molding companies can make sure the medical injection molding parts meet the requirements of use and safety if we select the right polymer resins, which are important to the medical device during the manufacturing process. Here are some common materials and they are widely used in medical devices:

Polyethylene(PE)

A

It is also called polythene that can be formulated in high or low densities. It is economic, resistant to impact and corrosion absorbs little water, and retains its overall performance and structural integrity after frequent sterilization cycles. A porous synthetic polymer, polyethylene is biologically inert, does not degrade in the body, and is often used in medical implants.

Polypropylene(PP)

A

It is a thermoplastic polymer used in all kinds of applications. Polypropylene is a white material that is mechanically rugged with high chemical resistance. It is commonly applied in disposable syringes, connectors, finger-joint parts, plastic containers, pharmacy bottles, and clear bags.

Polymethyl methacrylate(PMMA)

A

Poly(methyl methacrylate) is a common material used in modern dentistry. It is a good choice for the parts that require transparency, toughness, hardness, and almost perfect transmission of visible light. It is an ideal material to make a glass effection part.

Liquid Silicone Rubber(LSR)

A

Liquid silicone rubber is a high-purity, two-component platinum-cured silicone, normally processed through liquid injection molding (LIM). It is widely used in medical catheters, breathing masks, and rubber teats.

Polyamide(PA)

A

Polyamide, also named nylon, is a synthetic thermoplastic polymer that is commonly used for CNC machining, injection molding, and 3D printing. It can be combined with other materials to enhance its overall strength. It is a good choice for parts that see a lot of wear and tear.

Acrylonitrile butadiene styrene (ABS)

A

ABS has been widely applied in molding production also 3D-print manufacturing for OEMs. It shows the resistance of impact and heat features. It is also hard enough to make it as good engineering plastic. It can be used in injection molding, blow molding, extruding, and so on. Common uses include non-absorbent sutures, tendon implants, drug-delivery systems, and tracheal tubes.

Polycarbonate(PC)

A

Polycarbonate is also named PC. It shows naturally transparent and provides good UV protection. Polycarbonate is good for use in glass, shock-resistant, and medical grades can be sterilized at 120 °C. Polycarbonate is lightweight, provides chemical-, electrical-, heat- and impact resistance, stability, and high performance.

Custom Medical Plastic Injection Molding Device

Packson cooperates with all kinds of medical industries for offering plastic & silicone rubber injection molding services to assist design and medical plastic molding making, and medical molding parts. Please check below the medical markets that we serve:

Blood Testing ChipsBlood Testing Chips

Female external catheterFemale external catheter

Diagnostics electronic equipmentsDiagnostics electronic equipments

Diagnostic kitDiagnostic kit

Disposables Injection SyringeDisposables Injection Syringe

Surgical equipementSurgical equipement

Tests collection plastic containerTests collection plastic container

Tests collection plastic containerAnd more

Medical Plastic Injection Molding Finishes

Normal Finish

Normal Finish includes SPI B-3 to D-3. Our medical plastic injection molding companies will use this finish in a normal part without special finishing requirements.

MoldTech Finish

MoldTech is a famous finishing process supplier around the world. They make range finishings like:MT11010 MoldTech - MT11020 MoldTech - MT11030 MoldTech - MT112XX MoldTech - MT114XX MoldTech - MT116XX

SPI Finish

SPI is one of standards of finish. It includes SPI A-1 SPI A-2 SPI A-3 SPI B-1 SPI B-2 SPI B-3 SPI C-1 SPI C-2 SPI C-3 SPI D-1

Graining|Machining Finish

The part will show the original mark without secondary finishing.

在线联系供应商

Other supplier products

| One-stop Injection Molding Service Expert | ISO Class 8 Clean Room Quality Control Low & High Volume Manufacturing Competitive Price Reliability and Stability For more th... | |

| Silicone Rubber Injection Molding | Silicone rubber injection molding has more than a half-century history since the late 1970s. There are two molding ways of silicone rubber injectio... | |

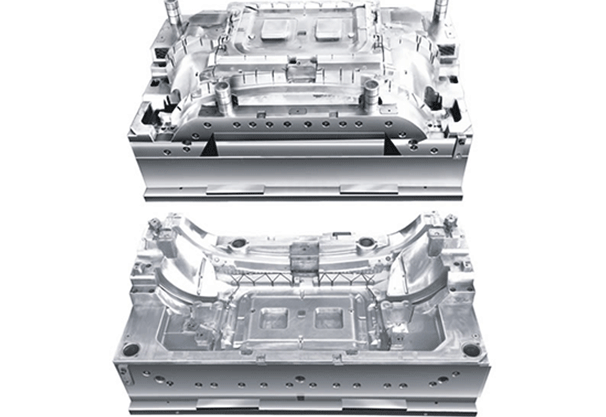

| Prototype Mold | Prototype molds are rapid processing for the molds. It's totally different from production molds as they can't be used in the long term. As a profe... | |

| Custom Contract Molding | Plastic Injection Molds for Sale Packson is the OEM injection mold maker in china. We can supply custom injection molding parts. Our high quality ... | |

| Clean Room Injection | Packson - Clean Room Injection Expert Packson specializes in delivering top-notch clean room manufacturing and assembly solutions tailored to meet... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |