Eddy Current Testing Equipment

ECT Eddy current testing used by eddy current testing machine is a non-contact testing method, which mainly uses the electromagnetic field and electromagnetic induction between metals to detect. It is one of the NDT non-destructive testing methods in the industry.

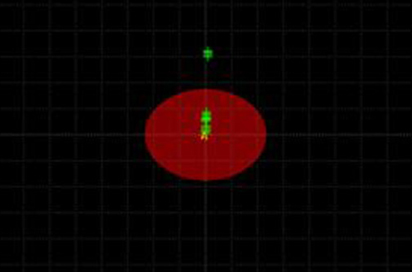

The principle of eddy current ndt equipment is that the coil with alternating current is placed on the metal plate to be measured or outside the metal, tube to be measured (see figure). The alternating magnetic field will be generated inside and near the coil, which makes the induced alternating current in the sample appear to be eddy, which is called eddy current. Under certain conditions, the current through the coil is invariable. If the coil is close to the workpiece under test, like a ship in the water, the eddy current will be induced in the workpiece. Under the influence of the eddy current, the coil current will change. Therefore, with this kind of eddy current apparatus, the defect in the workpiece can be shown by the change of coil current as the size of the eddy current varies with the defect in the workpiece.

Eddy Current Testing for Tube, Bar and Wire

Eddy current testing is a non-contact testing method, which mainly uses electromagnetic field and electromagnetic induction between metals to detect.

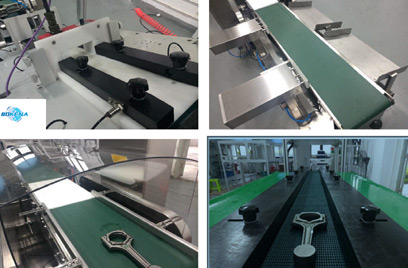

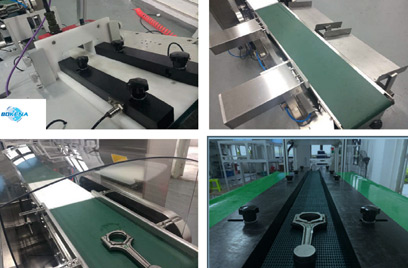

Eddy Current Testing for Auto Parts

Eddy current testing technology has been widely used in the detection of metal components in the aviation and aviation fields.

Eddy current test setis our flagship product. We are one of the best eddy current test equipment suppliersin China. It contains ECT testing equipmentfor tube, bar and wire & ECT equipment for automotive parts and aviation. ECT for tube, bar and wire including BKNET-999/H Copper Tube Eddy Current Flaw Detector, GSET-551steel wire eddy current testing, BKNET-101 Automatic Eddy Current Testing Instrument, Rod Tube Rotary Eddy Current Flaw Detector ET-R-15/40/65/90, BKNET-01�2 Welded Pipe Eddy Current Flaw Detector, LGET-553 Aluminum Tube Eddy Current Flaw Detector.

ECT testing equipment for automotive parts and aviation including BKNFX Pre-Multi-Frequency Eddy Current Hardness Separator, BKNET Series Multi-frequency and Multi-filter Eddy Current Flaw Detector, ET-F1 Engine Cylinder Bore Eddy Current Flaw Detector, GTET-02 Cylinder Liner Eddy Current Flaw Testing Machine, Steel Ball Hardness eddy current separator GQYDFX-01, GZET-01 Roller Automatic Eddy Current Flaw Testing Machine, Roller Hardness eddy current Separator GZYDFX-01, Piston Rod Eddy Current Flaw Detector HSGET-04, HSXET-02 Piston Pin Eddy Current Tester, Precision Axis Eddy Current Flaw Detector JMZET-04, Connecting Rod Hardness eddy current Sorting Machine LGYDFX-01, Hub Bearing Eddy Current Flaw Detector LGTSET-A/B, Bolt Vortex Sorter BKNFX-11, Flame Quenching Valve Rod End Hardness Eddy Current Sorter QMYDFX-01, QTXET-01 Ball Socket Eddy Current Sorter, QTXFX-01Ball Socket Hardness Eddy Current Sorter, SCPET-04 Brake Disc Eddy Current Flaw Detector, TLET-04 Camshaft Eddy Current Flaw Detector, TLZET-99 Camshaft Eddy Current Flaw Detector, Tapered Roller Online Eddy Current Flaw Detector YZGZET-01, Ring Crack and Hardness Combination Flaw Detector TQJC-02.

As an eddy current testing machine manufacturer, we have been committed to developing and manufacturing high-quality and high-performance NDTdeviceto provide customers with the best quality service.

在线联系供应商

Other supplier products

| RQ-120-B Automatic CNC EDM Notch | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKN Automation System Co., Ltd. for maki... | |

| Eddy Current Testing Equipment | Technical Characteristics of MFL101 mfl floor scanner Unique full modular structure, from the main body of the computer mechanism the handle of MFL... | |

| Bolt Vortex Sort BKNFX-11 | Bolt: Mechanical parts, cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external ... | |

| Magnetic Flux Leakage Testing Equipment | Electromagnetic detection is a very important non-destructive testing method and is widely used. Magnetic flux leakage testing is a magnetic method... | |

| Application of Ndt Inspection Equipment | Ndt inspection equipmentis widely used in industry, such as nuclear industry, weapon manufacturing, machinery industry, shipbuilding, petrochemical... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |