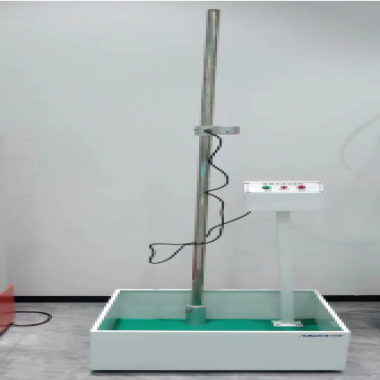

Thrust Washer Friction Testing Machine

The thrust washer friction testing machine is mainly used to simulate the frictional contact of materials under specific working conditions and to quantify the wear resistance and friction coefficient of materials.

Application

The end-face rotary friction and wear testing machine is mainly used to evaluate the wear resistance and tribological behavior of materials under rotating friction conditions. By simulating the actual working conditions of the material in the process of rotating friction, the testing machine can measure key parameters such as friction coefficient, wear amount and wear rate of the material, and then evaluate the wear resistance of the material quantitatively. This is of great significance for material research and development, product design, quality control and other fields.

Specifically, the main uses of end-rotating friction loss testing machines include:

Material tribological performance evaluation: By measuring the friction coefficient, wear amount and other parameters of the material, the tribological performance of the material is evaluated, which provides a basis for the selection and design of the material.

Lubricant performance evaluation: In the process of rotary friction, the use of lubricants has an important impact on the friction and wear properties of materials. The test machine can be used to evaluate the lubrication performance of lubricants under rotating friction conditions.

It provides reference for the selection and use of lubricants.

Durability test: For products that need to withstand rotating friction loads, such as mechanical seals, bearings, etc., the tester can be used to perform durability tests to assess the service life and reliability of the product.

Standards

When the end face rotary friction and wear testing machine is tested, it is usually necessary to follow certain standards and specifications. Here are some common applicable standards:

GB/T 12583-98: This standard specifies the test method of end-face rotary friction and wear testing machine, including the preparation of samples, the selection of test conditions, the recording and processing of test results, etc.

ASTM D: This is a standard developed by the American Society for Materials and Testing (ASTM) for the evaluation of thrust ring friction and wear performance test method. Although the standard is mainly aimed at thrust rings, the test methods and principles in it also have a certain reference value for the end face rotation friction and wear test.

Other industry or enterprise standards: In addition to the general standards mentioned above, different industries or enterprises may have developed specific test standards that may have specific requirements for specific material types, test conditions, or treatment of test results.

When conducting the test, it should be ensured that the selected standard is consistent with the test purpose and requirements, and the test methods and steps specified in the standard are strictly operated. At the same time, it is also necessary to pay attention to the calibration and maintenance of the testing machine to ensure the accuracy and reliability of the test results.

Feature

Versatility: Applicable to various friction types, including point contact, line contact, and surface contact.

High Precision: Employs a high-precision geared motor and sensors, supporting real-time load measurement.

Automation: The equipment features automated operation and supports one-click parameter setting.

Multiple Types: Available in various types based on friction method and friction pair differences, including four-ball, ring-block, high-temperature, and vacuum types.

Environmental Simulation: Some models can be expanded to accommodate different friction pair types, adapting to rolling, sliding, or combined motions, and feature high-temperature environment simulation capabilities.

Parameters

| Description | Details |

|---|---|

| Working range of axial test force (stepless adjustable) | 10 - 1000N |

| Relative error of test force | ±1% |

| Automatic retention of test force for long period (Display value error) | ±1% FS (Maximum test force) |

| Test force exceeding maximum test force | Alarm |

| Measuring range of friction force | 10~500N |

| Relative error of friction force | ±2% |

| Force value exceeds the difference | Automatic alarm |

| Spindle speed range | 50~2000r/min |

| Spindle speed range error | ±10r/min |

| Specimen seating stroke | >45mm |

| Spindle motor power | 4kW |

| Tester time display and control range | 1s~9999min |

| Test revolution display and control range | 9999999s |

| Overall size of the tester | Approx. 1200×870×1700mm |

| Net weight of testing machine | 850kg |

Accessoriess

High-temperature oil box; pin-plate friction pair; four-ball friction pair; thrust ring friction pair; lifting screw; collet and tie rod; spring collet, etc.

Test Procedures

Preparation: Select appropriate friction pair materials, load, speed, and other parameters, and inspect and maintain the testing machine.

Installing Friction Pairs: According to the test requirements, select appropriate friction pair materials and install them on the testing machine.

Adjusting the Load: Set an appropriate load to ensure the contact pressure between the friction pairs meets the requirements.

Setting the Motion Mode: According to the test requirements, set an appropriate motion mode, such as rotation, reciprocating, or oscillation.

Starting the Test: After setting the parameters according to the test requirements, start the testing machine for testing.

Data Recording: During the test, record the test data, including friction force, wear amount, etc.

After the Test: Clean the friction pairs and the inside of the testing machine, and perform maintenance.

When conducting friction and wear tests, operators need to possess certain professional knowledge and skills and operate according to the operating procedures. During the test, the operating status of the testing machine needs to be closely monitored. If any abnormality occurs, the machine should be stopped immediately for inspection. During use, the testing machine should be placed in a stable, dry environment, avoiding direct sunlight and humid environments.

在线联系供应商

Other supplier products

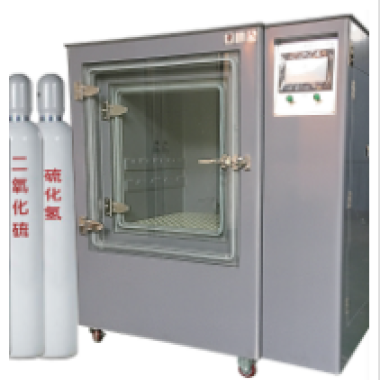

| Hydrogen Sulfide Corrosion Test Chamber | The Hydrogen Sulfide Corrosion Test Chamber is a precision environmental testing instrument designed to evaluate the corrosion resistance of metals... | |

| Finished shoes sole bending tester | Finished shoes sole bending testeris used to test shoe stiffness/rigidity by flex shoe to certain angle by certain force. The shoe bending stiff... | |

| Solid Combustion Rate Tester | This product complies with "Recommendations on the Transport of Dangerous Goods - Manual of Tests and Criteria" 33.2.1.4 Test N.1: Test Method fo... | |

| Digital display electronic ink viscosity meter | How it works: The working principle of the digital display electronic ink viscosity meter is based on two tin (usually a metal roller and a rubber... | |

| Falling ball impact testing machine | Product Introduction: Falling ball impact tester is suitable for testing the fastness of plastic, ceramic, acrylic, glass fiber and other material... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |