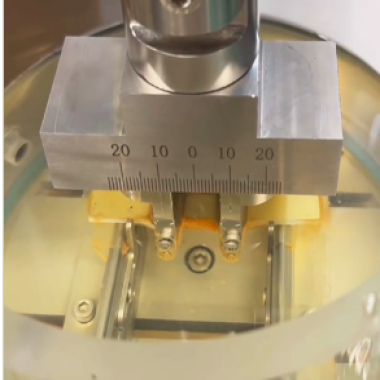

Chin Strap Testing Machine

Standard GB/T 2812-2006: Safety Helmets GB/T 2811-2019: Head Protection – Vocabulary and Test Methods Equivalent Compliance: ISO/EN 397 (Industrial Safety Helmets) CE Certification (Conformité Européenne) Product Advantages Multi-Standard Compliance 150N Load Capacity: Simulates extreme impact forces per GB/T 2812. 20N/min ±2N/min Control: Ensures repeatable tensile testing for global certifications. Ultra-Precise Measurement 0.1N Resolution: Captures subtle strap elongation before failure. 2,000N Force Range: Tests industrial to sports helmets with one machine. User-Centric Design Quick-Release Head Model: Swap mandibles in seconds for multi-helmet testing. LED Real-Time Display: Visualizes force curves during dynamic loading. Durability Aircraft-Grade Aluminum Frame: Resists deformation under 2,000N max load. Corrosion-Resistant Sensors: Stainless steel construction for humid environments. Safety First Emergency Shutoff: Dual redundant safety circuits with load cell override. Overload Protection: Auto-pause at 2,200N to prevent equipment damage. Product Features Motorized Tensile Stage: 0–500 mm/min adjustable speed with force-displacement graphing. Modular Head Assembly: Fits adult, child, and custom helmet sizes (50–65 cm circumference). Dynamic Force Feedback: 0.1N resolution load cell with peak force memory. Self-Calibrating System: Auto-tare and linearity checks before each test. Rust-Resistant Frame: 304 stainless steel construction with epoxy coating. Technical Parameters Parameter Specification Force Range 0–2,000N (200 kgf capacity) Load Rate 20N/min ±2N/min (adjustable) Max Load Time 150N achieved within 60s Force Resolution 0.1N (10 gf) Head Model Quick-swap anthropomorphic mandible Power Supply 220V AC, 50/60Hz (single-phase) Dimensions 600mm (W) × 450mm (D) × 1,200mm (H) Weight 80 kg (net) Accessories Included Testing Kit: 2x Adult-Size Head Forms (56cm/58cm circumference). 5x Calibration Grade Load Cells (10N–2,000N). Software Suite: License key for ChinStrapTest Pro (Windows/macOS). 1-year free access to cloud-based tensile analysis tools. Calibration & Safety: NIST-traceable force gauge. 2x Safety Glasses (EN 166 rated). Maintenance Kit: Spare drive belts and bearings. Machine cleaning solution (non-corrosive). Documentation: Multilingual quick-start guide (printed + digital). Compliance certificates for GB/T/ISO standards.

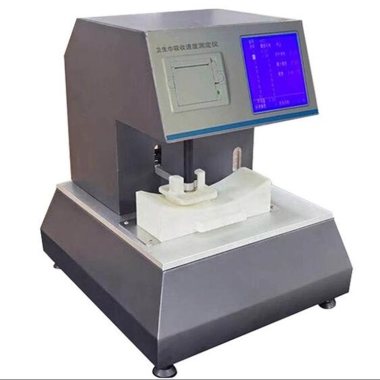

Other supplier products

供应产品

Same products