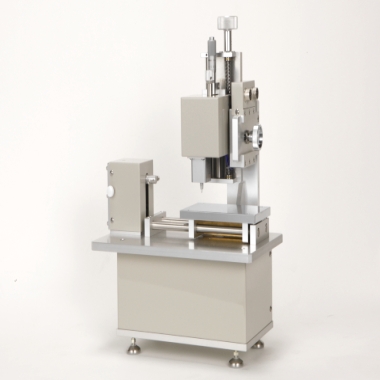

E-bike chassis dynamometer testing machine

Electric bicycles are complex systems involving mechanical, electrical, and control components. Evaluating their performance and compliance with safety and efficiency standards requires precise and repeatable testing that is difficult to achieve in outdoor environments due to varying weather, traffic, and road conditions. An Electric Bicycle Chassis Dynamometer System addresses this need by providing a consistent platform for comprehensive e-bike testing.

Standard

EN 15194:Cycles - Electrically power assisted cycles - EPAC Bicycles

ISO 4210:Cycles - Safety requirements for bicycles

UL 2849:Standard for Electrical Systems for eBikes

Application

Measuring motor efficiency, power output, and torque characteristics of e-bikes.

Evaluating battery range and energy consumption under simulated riding conditions.

Simulating various road loads, inclines, and driving cycles.

Testing electromagnetic compatibility (EMC) by providing a stable environment.

Conducting endurance and durability testing on e-bike components.

Verifying compliance with national and international standards for e-bike performance and safety.

Research and development of new e-bike designs, motors, batteries, and control strategies.

Quality control and validation during the e-bike manufacturing process.

Product Advantages

Provides a highly controlled and repeatable testing environment, eliminating variables from outdoor riding.

Enables precise and accurate measurement of critical e-bike performance parameters.

Allows for rapid and efficient testing for product development and quality control.

Enhances safety by performing tests in a controlled indoor setting rather than on roads.

Supports compliance testing against various national and international e-bike standards.

Facilitates detailed data acquisition and analysis for in-depth performance evaluation.

Offers versatility to simulate a wide range of riding conditions and custom test cycles.

Accommodates various e-bike types and sizes through adjustable mounting systems.

Parameters

| Item | Detail |

|---|---|

| Loading Method | Inertia |

| Maximum Power | 200 kW (300 HP) |

| Max Speed | 350 km/h |

| Roll Inertia | 8.16 m²·kg |

| Roll Diameter | 450 mm |

| Roll Width | 235 mm |

| Max Impasto | 1.57 m |

| Vehicle Size | e - bike |

Accessoriess

Roller

Power absorption device

Inertia simulation device

Drive motor

Speed sensor, etc.

Test Procedures

Preparation: Ensure the dynamometer is in good working order and prepare the necessary tools and equipment for the test. Check that the electric vehicle under test meets the test requirements, such as being fully charged and free of malfunctions.

Connect the power supply: Connect the electric vehicle to the dynamometer and switch on the power. At this point, the dynamometer should be in a "no-load" state.

Set parameters: Set the appropriate parameters according to the test requirements, such as test time and speed range.

Start the test: After confirming that all parameters are set correctly, start the test program. The dynamometer will perform the test according to the set parameters and record the test data.

End the test: After the test is completed, close the test program, disconnect the power supply, and remove the electric vehicle. The test results can then be viewed and data analysis can be performed.

在线联系供应商

Other supplier products

| Aerosol Foams Flammability Tester | Product Introduction This product complies with "Recommendations on the Transport of Dangerous Goods - Manual of Tests and Criteria" 31.6 Flammabi... | |

| Minimum Ignition Energy (MIE) – Dust Cloud Tester | Dust Cloud Minimum Ignition Energy Tester disperses a certain mass of dust specimen to be tested into the Hartmann tube device through a certain pr... | |

| Plastic Ball Indentation Hardness Measuring Device | Scope of application: It is used to measure the characteristics of the plastic drainage plate in the plane direction of the water flow under the s... | |

| ROSS zigzag tester | Product Introduction: The ROSS zigzag resistance tester installed the sole strip test piece on the ROSS zigzag test machine, so that the cut is di... | |

| Femoral Condyles Components Fatigue Performance Tester | Standard ASTM WK51649: Specifies fatigue testing protocols for metallic femoral components in total knee arthroplasty, including F-N curve generat... |

Same products

| Gas Oxidizing Property Tester | 卖方: Standard International Group (HK) Limited | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylind... | |

| Battery Powder Compaction Density Measurement System | 卖方: Standard International Group (HK) Limited | The Battery Powder Compaction Density Measurement System is a precision testing system designed... | |

| Battery Powder resistance tester | 卖方: Standard International Group (HK) Limited | The Powder Resistivity Meter is a precision testing system designed to measure electrical resisti... | |

| KES-SESRU surface roughness/friction tester | 卖方: Standard International Group (HK) Limited | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans ... | |

| Air Permeability Tester STD- F8 | 卖方: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... |