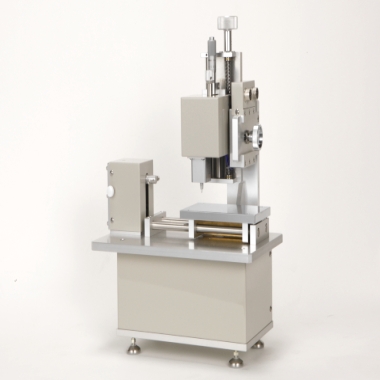

Appliance Stability Tester

The Appliance Stability Tester is designed to evaluate the mechanical stability and anti-tipping safety of household and similar electrical appliances when placed on an inclined supporting surface. By tilting the test platform to specified angles in accordance with international safety standards, the tester objectively determines whether an appliance will overturn under normal or foreseeable misuse conditions. It is an essential safety compliance instrument for appliance manufacturers, testing laboratories, and certification bodies.

Application

(1) Stability testing of large household appliances (refrigerators, freezers, washing machines, dryers)

(2) Stability assessment of kitchen appliances installed on floors or countertops (dishwashers, ovens, microwave ovens)

(3) Mechanical stability evaluation of air conditioners, dehumidifiers, and similar floor-standing appliances

(4) Safety testing of commercial and light industrial electrical appliances requiring surface operation

(5) Compliance testing during product certification, type testing, and factory quality control

(6) R&D evaluation of structural design and center-of-gravity optimization for new appliance models

Standards

(1) GB 4706.1 — Household and similar electrical appliances – Safety – Part 1: General requirements (Clause 20.1 Stability)

(2) IEC 60335-1 — Household and similar electrical appliances – Safety – Part 1: General requirements (Clause 20.1 Stability)

(3) EN 60335-1 — European adoption of IEC 60335-1 (Stability requirements)

(4) GB/T 21547-2008 — Safety requirements for household and similar electrical appliances (related stability clauses)

(5) UL 60335-1 — Safety of Household and Similar Electrical Appliances (stability-related requirements)

Features

(1) Fully compliant with major national and international appliance safety standards

(2) Adjustable tilt angle mechanism to accurately simulate standard-required inclination conditions

(3) Rigid and stable workbench capable of supporting heavy appliances

(4) Simple mechanical structure with intuitive operation

(5) Suitable for a wide range of appliance sizes and weights

(6) Enables objective and repeatable evaluation of tipping and sliding risks

Parameters

| Item | Description |

|---|---|

| Work surface | Flat workbench with integrated angle adjustment mechanism |

| Load capacity | ≤ 100 kg |

| Angle adjustment range | 0° – 15° (typical), higher angles optional |

| Angle accuracy | ±0.5° |

| Rotation function | Rotatable platform, adjustable speed |

| Vibration simulation | Frequency range 5 – 200 Hz (optional) |

| Measurement system | Force sensor and displacement measurement (optional) |

| Safety protection | Emergency stop button, anti-tipping brackets |

| Power supply | AC 220 V, 50 Hz (if motorized functions applied) |

Accessories

(1) Adjustable angle positioning mechanism

(2) Appliance fixing and anti-slip supports

(3) Safety protection guards and emergency stop device

(4) Optional vibration simulation and measurement modules

Test Procedures

(1) Place the appliance under test on the workbench in its normal operating position

(2) Adjust the platform orientation to the most unfavorable direction as specified by the relevant standard

(3) Gradually tilt the platform to the required test angle

(4) Observe whether the appliance tips, slides, or remains stable

(5) Record the test angle and stability behavior

(6) Repeat the test for all required orientations and configurations

Maintenance Information

(1) Regularly inspect the angle adjustment mechanism for smooth operation

(2) Keep the workbench surface clean and free from oil or debris

(3) Periodically verify angle accuracy using calibrated measuring tools

(4) Check safety guards, fasteners, and emergency stop function before testing

(5) Store the equipment in a dry environment to prevent corrosion and mechanical degradation

在线联系供应商

Other supplier products

| Pressure Transmission Flow Meter Test Instrument | The Pressure Transmission and Flow Tester is widely used in multiple fields and is mainly used to test the pressure transmission and flow performan... | |

| Abrasive Wear Test Apparatus | Standard ASTM G65 - 04 GB/T 3960-1983 Main Purposes The wet - type rubber wheel abrasive wear testing machine is primarily employed to assess t... | |

| ASTM G155 Test Chamber | Features and Benefits 1.ASTM G155 test chamberadopts xenon arc lamp as light source, producinghigh intensity and stable light, posing good simulat... | |

| Infusion device Leakage negative pressure tester | The Infusion Device Leakage Negative Pressure Tester is designed to evaluate the airtightness of syringes, infusion sets, and related medical devic... | |

| KES-SESRU surface roughness/friction tester | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans and professionals when judging a fabric' s texture... |

Same products

| Gas Oxidizing Property Tester | 卖方: Standard International Group (HK) Limited | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylind... | |

| Battery Powder Compaction Density Measurement System | 卖方: Standard International Group (HK) Limited | The Battery Powder Compaction Density Measurement System is a precision testing system designed... | |

| Battery Powder resistance tester | 卖方: Standard International Group (HK) Limited | The Powder Resistivity Meter is a precision testing system designed to measure electrical resisti... | |

| KES-SESRU surface roughness/friction tester | 卖方: Standard International Group (HK) Limited | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans ... | |

| Air Permeability Tester STD- F8 | 卖方: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... |