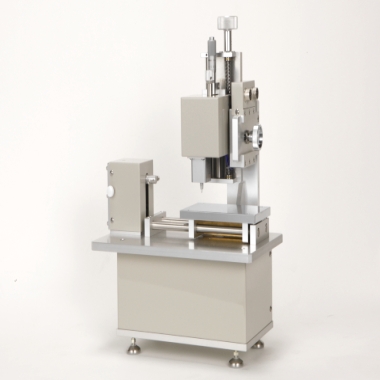

Safety shoe impact testing machine

The Safety Shoe Impact Testing Machine is designed to evaluate the impact resistance of protective toecaps in safety footwear by simulating the effect of falling objects under controlled and repeatable conditions. By applying a specified impact energy through a standardized drop hammer, the tester measures the protective performance of the shoe toe area and verifies compliance with international and national safety footwear standards. The equipment is essential for certification testing, quality control, and product development in the safety footwear industry.

Application

The testing machine is suitable for impact resistance evaluation of a wide range of protective footwear and components. Typical application scenarios and products include:

(1) Industrial Safety Shoes – steel toe shoes, composite toe shoes, aluminum toe shoes used in construction, manufacturing, and heavy industry.

(2) Protective Work Boots – mining boots, oil and gas safety boots, logistics and warehouse safety footwear.

(3) Electrical Safety Footwear – electrically insulating safety shoes with impact-resistant toecaps.

(4) Military and Police Footwear – combat boots and tactical safety footwear with reinforced toe protection.

(5) Occupational Footwear for Utilities – power grid, telecommunications, and municipal service safety shoes.

(6) Safety Footwear Components – steel toe caps, composite toe caps, plastic toe caps tested independently before assembly.

(7) Footwear R&D and Design Validation – comparative testing of new materials and toecap structures.

(8) Quality Inspection and Certification – factory quality control, third-party laboratories, and government inspection agencies.

Standards

The Safety Shoe Impact Testing Machine complies with and supports testing according to the following international and national standards:

(1) EN ISO 20344 – Personal protective equipment – Test methods for footwear

(2) EN ISO 20345 – Safety footwear

(3) EN ISO 20346 – Protective footwear

(4) EN ISO 20347 – Occupational footwear

(5) EN 12568 – Foot and leg protectors – Requirements and test methods for toecaps

(6) BS EN 344 – Safety, protective and occupational footwear for professional use – Test methods

(7) BS 953 – Specification for steel toe caps for safety footwear

(8) ANSI Z41 – Personal protection – Protective footwear (superseded but still referenced)

(9) ASTM F2412 – Standard test methods for foot protection

(10) ASTM F2413 – Standard specification for performance requirements for protective footwear

(11) CSA Z195 – Protective footwear (Canada)

(12) AS/NZS 2210.2 – Occupational protective footwear – Test methods (Australia/New Zealand)

(13) JIS T8101 – Safety shoes (Japan)

(14) CNS 6863 – Safety footwear

(15) GB/T 20991 – Personal protective equipment – Safety footwear (China)

(16) GB 4014-1983 – Steel toe caps for safety footwear (China)

(17) LD 50 – Labor protection footwear standards (China, historical reference)

Product Advantages

(1) Measures critical safety properties by quantifying the impact resistance of safety shoe toecaps.

(2) Simulates real-world impact hazards caused by falling or dropped objects.

(3) Complies with multiple international standards through configurable hammer weights and drop heights.

(4) Provides objective and repeatable test results based on residual internal height and deformation.

(5) Supports both finished footwear and separate toe cap testing.

(6) Robust mechanical structure ensures long-term stability under repeated high-energy impacts.

(7) Essential equipment for product certification, factory inspection, and laboratory testing.

Product Features

(1) Drop hammer mechanism with controlled vertical guidance for accurate impact positioning.

(2) Interchangeable standard drop hammer weights to meet different test standards.

(3) Adjustable falling height to generate required impact energies.

(4) Capability to achieve standard impact energies such as 200 J and 100 J.

(5) Standardized impact edges with different geometries according to test standards.

(6) Rigid anvil and baseplate to ensure stable shoe positioning during testing.

(7) Dedicated fixture for secure mounting of safety shoes or toe caps.

(8) Residual height measuring system for post-impact evaluation.

(9) Electric motor drive for lifting the drop hammer to the preset height.

(10) Heavy-duty frame design to minimize vibration and ensure operator safety.

Technical Parameters

| Parameter | Specification |

|---|---|

| Drop Hammer Weight | (EN) 20 ± 0.2 kg; (BS / ANSI) 22.7 kg |

| Falling Height | (EN) 0 – 1100 mm |

| Impact Energy | (EN) 200 J; (BS / ANSI) 100 ± 2 J |

| Impact Edge | (EN) R 3 ± 0.1 mm; (ANSI) Ø 25.4 mm |

| Motor Power | DC 1/4 HP |

| Machine Dimensions | 58.5 × 69.5 × 181.5 cm |

| Machine Weight | Approx. 227 kg |

| Power Supply | Single phase, AC 220 V |

Accessories

(1) Standard drop hammer set (EN / BS / ANSI) – 1 set

(2) Shoe holding fixture – 1 set

(3) Residual height measuring device – 1 set

(4) Power cable – 1 piece

(5) User operation manual – 1 copy

Maintenance Information

(1) Regularly inspect the drop hammer guide rails for wear and alignment.

(2) Verify hammer weight and falling height calibration periodically.

(3) Keep the anvil surface clean and free of debris.

(4) Lubricate moving mechanical components as specified in the maintenance manual.

(5) Store the machine in a dry environment to prevent corrosion.

在线联系供应商

Other supplier products

| Photovoltaic module insulation resistance tester | The Photovoltaic Module Insulation Resistance Tester is a precision instrument designed for simultaneous measurement of insulation resistance and l... | |

| Water-cooled Light & Weather Fastness Tester | Water-cooled Light & Weather Fastness Tester Test for color fastness to sunlight of material SI4000 water cooled sunlight fastness tester -The... | |

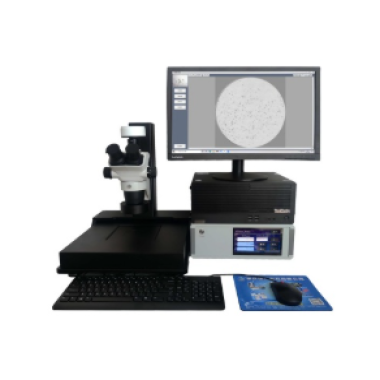

| Purity Analysis System | Production: The cleanliness analysis system fully complies with the requirements of standards such as VDA19.1 - 2015. ISO16232. ISO4406. ISO4407. ... | |

| SUGA S80 Carbon Arc Weathering Tester | Applicable Standards The SUGA S80 adheres to globally recognized standards, including: ISO, AATCC, ASTM(e.g., ASTM G152. ASTM D822 for coatings) ... | |

| KES-SESRU surface roughness/friction tester | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans and professionals when judging a fabric' s texture... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | 卖方: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | 卖方: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | 卖方: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | 卖方: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | 卖方: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |