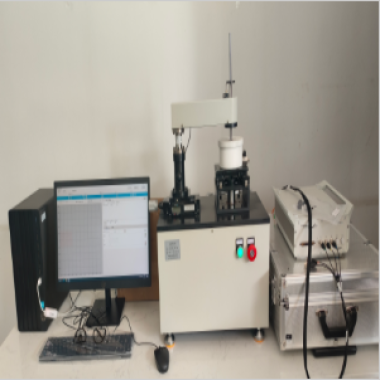

In-situ expansion analysis system

The In-situ Expansion Analysis System is designed for high-precision measurement of dimensional and volumetric changes in electrochemical cells and related materials during charge/discharge, storage, and abuse testing. The system enables real-time, non-destructive monitoring of cell expansion behavior under controlled temperature, pressure, and environmental conditions. It is widely used in lithium-ion, solid-state battery R&D, safety evaluation, and reliability testing.

Application

(1) In-situ expansion and swelling analysis of lithium-ion pouch, prismatic, and coin cells during charge/discharge cycles.

(2) Dimensional change monitoring of solid-state batteries and solid electrolytes under electrochemical loading.

(3) Thermal expansion and contraction testing under wide temperature ranges for battery reliability studies.

(4) Pressure-coupled expansion analysis for pouch cell fatigue and mechanical stability evaluation.

(5) Correlation analysis between expansion, voltage, cycle life, and degradation mechanisms.

(6) Abuse and reliability testing including overcharge, fast charging, and thermal stress conditions.

Standards

(1) ASTM E83 – Standard Test Method for Verification of Linear Displacement Measuring Systems.

(2) ISO 12417-1 – Mechanical Testing of Metals – Dilation Test.

(3) IEC 62660-2 – Secondary lithium-ion cells for propulsion of electric road vehicles – Reliability and abuse testing.

(4) DIN 51221 – Testing of adhesives – Determination of tensile shear strength (dimensional deformation reference).

(5) CE Certification – Conformité Européenne.

Features

(1) Sub-micron displacement resolution down to 0.01 μm for precise expansion measurement.

(2) Non-contact laser displacement sensors eliminate mechanical interference and measurement hysteresis.

(3) Multi-environment testing with integrated temperature chamber covering –40°C to 200°C.

(4) Dynamic pressure loading up to 50 bar for pouch cell fatigue and mechanical stress testing.

(5) Real-time 3D deformation imaging with structured light scanning technology.

(6) AI-assisted deformation analysis for quantification of anisotropic and localized swelling.

(7) Multi-channel architecture supporting up to 8 cells tested simultaneously.

(8) Automatic test sequencing with preloaded protocols for common battery test scenarios.

(9) Open data interface for synchronization with EIS, gas analysis, and thermal imaging systems.

Parameters

| Parameter | Specification |

|---|---|

| Displacement Range | ±500 μm (linear), ±1° (angular) |

| Measurement Accuracy | ±0.1 μm (linear), ±0.01° (angular) |

| Resolution | 0.01 μm |

| Temperature Range | –40°C to 200°C |

| Temperature Ramp Rate | Up to 1°C/min |

| Pressure Range | 0–50 bar (dynamic loading) |

| Channel Capacity | Up to 8 channels |

| Data Acquisition Rate | 10,000 points/s per channel |

| Power Supply | 100–240 V AC, 50/60 Hz |

| Dimensions (W×D×H) | 800 × 600 × 1200 mm |

| Weight | 220 kg (net) / 280 kg (gross) |

Accessories

(1) Non-magnetic sample holders for coin cells, pouch cells, and prismatic cells.

(2) Disposable strain gauges (optional auxiliary measurement).

(3) Laser displacement sensor calibration standards (NIST-traceable).

(4) Integrated temperature and pressure control modules.

(5) Data acquisition and analysis software package.

(6) Inert gas purification cartridge and environmental monitoring sensors.

(7) User manual and maintenance documentation.

Test Procedures

(1) Install the test cell into the appropriate sample holder and align using the laser positioning system.

(2) Configure test parameters including temperature profile, pressure loading, channel selection, and data acquisition rate.

(3) Connect the system to external electrochemical testers if synchronized testing is required.

(4) Start the test sequence; the system records displacement, temperature, pressure, and auxiliary signals in real time.

(5) Monitor expansion behavior during testing and export data for further analysis and reporting.

Maintenance Information

(1) Regularly inspect laser sensors, optical components, and mechanical fixtures for contamination or misalignment.

(2) Perform periodic calibration using certified displacement standards.

(3) Check temperature chamber seals, pressure components, and safety interlocks routinely.

(4) Keep optical windows and sensor surfaces clean to maintain measurement accuracy.

(5) Update software and back up data according to laboratory quality management requirements.

在线联系供应商

Other supplier products

| Spring torsion fatigue testing machine | The Spring Torsion Fatigue Testing Machine (horizontal type) is an advanced automatic torsional fatigue testing instrument with digital display and... | |

| Xenon Arc Chamber | Features and Benefits 1. According to different specimens, xenon aging test chamber has a variety of models to choose from; For flat specimens, ro... | |

| Micro-hole Detection Instrument | The pinhole tester for aluminum foil is a device specifically used to detect micro - pinholes in aluminum foil materials. The following is a detail... | |

| Puncture Strength Tester STD - NDG5 | Compliance Standards ASTM D638 (Plastics Tensile Properties) ISO 13934-1 (Textile Tensile Strength) SAE J2749 (Automotive Composite Testing) JI... | |

| Electrochemical Corrosion and Wear Testing Machine | Electrochemical corrosion and wear testing machines are widely used in materials science, mechanical engineering, electronic engineering, aerospace... |

Same products

| Falling Sand Abrasion Test machine | 卖方: Standard International Group (HK) Limited | The sand abrasion tester is a specialized testing device used to evaluate the abrasion resistance... | |

| Conveyor Belt Drum Friction Testing Machine | 卖方: Standard International Group (HK) Limited | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction tes... | |

| Dry Sand Rubber Wheel Wear Tester | 卖方: Standard International Group (HK) Limited | The dry sand rubber wheel abrasion tester is mainly used to test the abrasion resistance of mater... | |

| Sliding Bearing Fatigue Testing Machine | 卖方: Standard International Group (HK) Limited | The sliding bearing fatigue testing machine is an important testing device, mainly used to evalua... | |

| High temperature vacum friction & wear tester | 卖方: Standard International Group (HK) Limited | The working principle of a high-temperature vacuum friction and wear testing machine is to simula... |