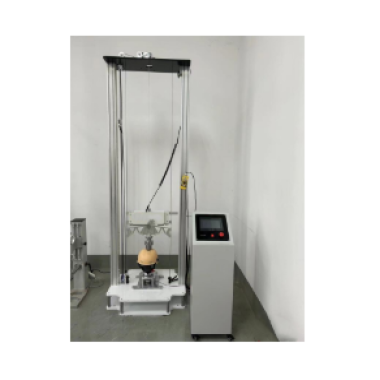

Computer-controlled Helmet Impact Tester

A computer-controlled helmet impact tester is an instrument used to test the impact resistance and penetration resistance of helmets. It quantitatively measures the impact resistance and energy absorption capacity of helmets by simulating the impact of objects falling from a height. The core principle of the testing instrument is the law of conservation of energy and the momentum theorem. During testing, the impact hammer is raised to a specified height, released, and allowed to fall freely, converting potential energy into kinetic energy to deliver a sudden impact to the helmet sample.

Application

This testing instrument is applicable to the impact - energy absorption performance test of helmets. It is used to evaluate the impact - resistance performance and penetration - resistance of helmets.

Standard

GB 811:Helmets for motorcycle and electric bicycle users

GB 24429:Sports helmets - Safety requirements and testing methods for sports helmets for cyclists and users of skateboards and roller skates

GB/T 38305-2019:Head protection—Rescue helmets

GA 44:Helmets for firemen

IS 4151:Helmet Standard for India

DOT FMVSS No. 218:Federal Motor Vehicle Safety Standard No. 218

ECE R22.05:Uniform Provisions Concerning the Approval of Protective Helmets and Their Visors for Drivers and Passengers of Motor Cycles and Mopeds

EN 1078:Helmets for cyclists and for users of skateboards and roller skates

Feature

High Precision: Utilizes a servo motor and hollow gear reduction system to ensure high accuracy and reliability of testing.

Automation: Automatically lifts the fixture to a predetermined height, displaying height, peak acceleration, test curve, impact velocity, impact time, and impact energy in real time.

Multifunctional: Employs a direct-drive transmission system with high positioning accuracy, long lifespan, low friction, and capable of high-speed and bidirectional rotation.

Safe and Fast: Features a position limiting function, making tests with position limitations safer and faster.

Wide Application Range: Offers a very wide measurement range, suitable for standards in multiple countries.

Integrated Design: Adopts an integrated design principle; regardless of the host configuration, only the corresponding parameters on the computer need to be modified (parameters can be saved), eliminating the need for circuit adjustments.

Parameters

| System Component/Feature | Description |

|---|---|

| System components | Consists of a crash test stand and an analysis recorder |

| Crash test bench composition | Comprises a fall guidance device, head type, head type fixed frame, ball joint, anvil, anvil seat, release guidance system, and seat base, among other components |

| Impact height | Control interface setting, with guidance system, acceleration detection and calibration device (customizable from 1000 ~ 3000mm) |

| Base | Optimal solution is made of reinforced concrete; the instrument's steel base is connected to the concrete base, with a mass not less than 1600kg |

| Test and Analysis Instrumentation System | Comprises acceleration sensors or impact sensors, amplifiers, and components for data processing, display, and recording, among others |

| Dimensions (LWH cm) | 9080450 (according to the set impact height) |

| Weight (kg) | 350 |

| Power supply | AC 220V 50Hz 500W |

| Environment | 10 ~ 35 ℃ |

| Operation | On the floor, connected to the concrete pedestal |

Accessoriess

Headform

Impact hammer

Penetration hammer

Accelerometer

Infrared speed sensor

Control board

Control box

Main unit

Dedicated computer and control software

Test Procedures

Sample preparation: Mount the helmet onto the appropriately sized test headform as required, and connect the power supply.

Open the computer software: Simultaneously click the touchscreen control screen to start the test.

Start the test: Start the testing machine, causing the pendulum to impact the headform with a predetermined energy.

Data analysis: Record and analyze the waveform data to evaluate the helmet's impact absorption performance and rotational kinematics.

在线联系供应商

Other supplier products

| Bubble Leak Tester | Main Uses Medical Device Packaging Inspection:The Gross Leak Tester can be used for the sealing performance testing of various medical device pack... | |

| Surgical Mask Flame Retardant Tester | Flame-retardant tester for surgical mask, In case of the mask is accidentally exposed to flame, its flame-retardant performance is directly related... | |

| Safety Helmets Impact and Penetration Resistance Tester | The Safety Helmets Impact and Penetration Resistance Tester is a dual-function testing system designed to evaluate helmet safety under both impact ... | |

| Heat Storage Performance Tester | Heat Storage Performance Tester provides standardized procedures and controls radiation heat conditions, providing repetitive measurement for heat ... | |

| Shoe heat insulation testing machine -- sand bath | The sand bath component of the shoe heat insulation testing machine is primarily used to test the heat insulation or thermal insulation performance... |

Same products

| Falling Sand Abrasion Test machine | 卖方: Standard International Group (HK) Limited | The sand abrasion tester is a specialized testing device used to evaluate the abrasion resistance... | |

| Conveyor Belt Drum Friction Testing Machine | 卖方: Standard International Group (HK) Limited | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction tes... | |

| Dry Sand Rubber Wheel Wear Tester | 卖方: Standard International Group (HK) Limited | The dry sand rubber wheel abrasion tester is mainly used to test the abrasion resistance of mater... | |

| Sliding Bearing Fatigue Testing Machine | 卖方: Standard International Group (HK) Limited | The sliding bearing fatigue testing machine is an important testing device, mainly used to evalua... | |

| High temperature vacum friction & wear tester | 卖方: Standard International Group (HK) Limited | The working principle of a high-temperature vacuum friction and wear testing machine is to simula... |