Clean Room Injection

Packson - Medial Injection Moulding Cleanroom Expert

Packson specializes in delivering top-notch clean room manufacturing and assembly solutions tailored to meet the needs of medical device companies. Committed to adhering to the ISO 13485 standard, which is the gold standard for quality management systems in the medical device industry, we ensure the highest level of quality and safety for our products.

Based on the specific requirements of the medical device, Packson can achieve ISO Class 7&8 classifications, providing controlled environments with particle counts ranging from 10,000 to 100,000 particles per square foot. Our team is composed of seasoned professionals with extensive experience in navigating the intricacies of the medical industry. From initial prototype design to final product delivery, we offer comprehensive medical device production services, ensuring a seamless journey from concept to market.

Get in touch with Packson and discuss your project requirements! We are dedicated to promptly responding to inquiries, typically within one business day, and are eager to explore how they can support your specific needs and bring your medical device project to fruition.

Packson Clean Room Injection Molding

Packson's clean room manufacturing and assembly services encompass a comprehensive range of capabilities. These include:

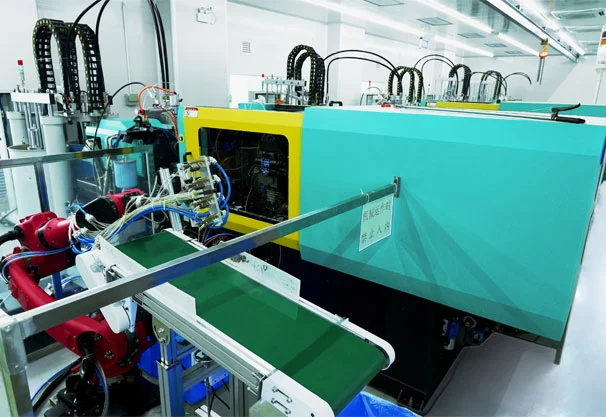

ISO Class 8 Cleanroom Injection

Laser Welding

Bonding (UV and solvent)

Decorating

Flaring

Tipping

Packaging (pouch and tray)

Force testing (pull force, burst, and torque)

IQ/OQ/PQ validations

With our expertise in these areas, Packson is well-equipped to handle diverse medical device projects and deliver high-quality products that meet stringent industry standards.

Packson Medical Device Cleanroom Capabilities

At Packson, we take great pride in our advanced medical grade silicone injection molding cleanroom, meticulously designed to meet the most stringent cleanliness requirements. Our cleanroom provides the ideal environment for producing medical devices of unparalleled quality, combining various materials with precision to cater to our customers' unique demands.

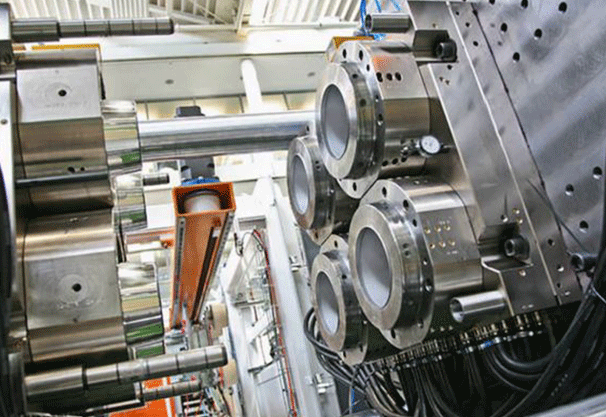

Our Commitment to Efficiency and Excellence: State-of-the-Art Equipment: Equipped with cutting-edge technology, our cleanroom houses the latest injection molding machinery to ensure precise and efficient production processes.

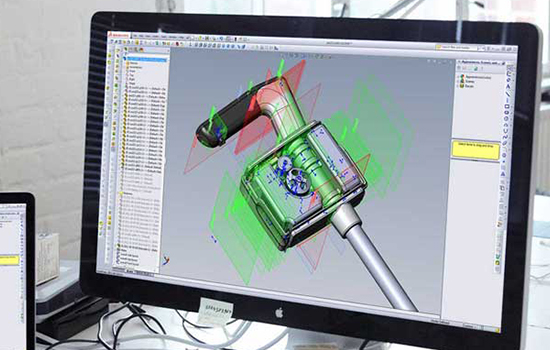

Skilled Engineers: Our team of highly skilled engineers brings their expertise to every project, reducing the risk of errors and streamlining the manufacturing process.

Time and Cost Savings: By leveraging our advanced technology and skilled workforce, we have significantly reduced project lead times and overall costs, translating into greater efficiency for our customers.

Meeting the Demands of the Medical Industry: As a leading clean room injection manufacturer , we are dedicated to serving the needs of the medical industry. Our medial injection moulding cleanroom facilitates the molding and assembly of medical devices, utilizing a wide array of materials, including medical-grade thermoplastics, to meet various healthcare and medical standards.

Focused on Precision and Scale: From small-batch productions to high-volume manufacturing, our cleanroom remains committed to creating precise medical components. Operating within ISO Class 7&8 cleanroom environments, we maintain the highest level of cleanliness and quality assurance.

Value-Added Services for Comprehensive Solutions: To provide a full spectrum of OEM medical device injection molding services, we offer a range of value-added services such as ultrasonic welding, printing, assembling, packaging, and sterilization. This comprehensive approach ensures that our customers receive end-to-end solutions tailored to their requirements.

If you are interested in our cutting-edge medical silicone overmold inje cleanroom and wish to learn more, please don't hesitate to contact us today. Our team is ready to address any inquiries and collaborate with you to bring your medical device projects to fruition.

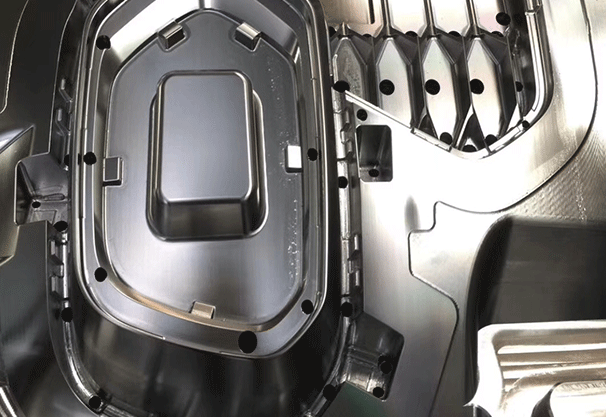

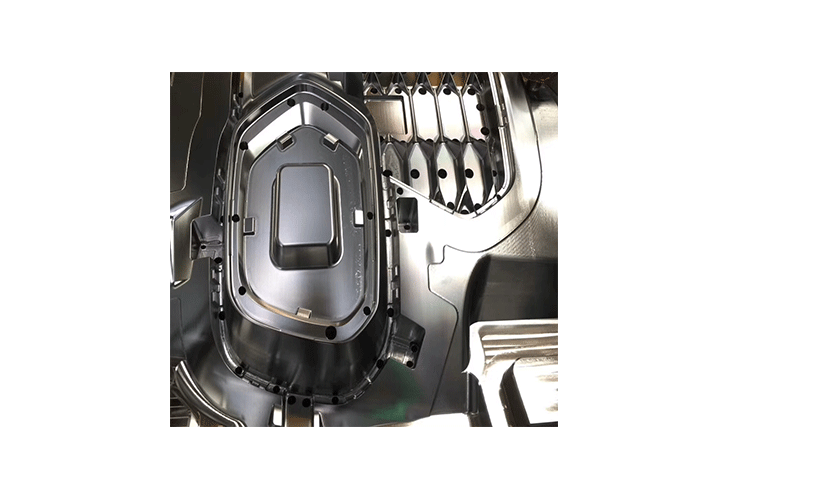

Packson Clean Room Injection Molding Process

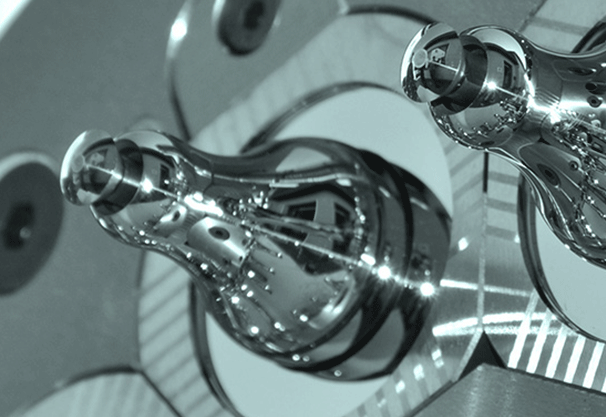

Our clean room injection molding parts are made by injection mold. The first step for making mold is to review the part design. Our medical device injection molding normally can reach 100,000 cycles even more if we use suitable steel material for the mold. Packson offers clean room silicone moulding services of a lifetime warranty for molds by mold maintaining. Here we have a professional engineering team that is dedicated to your injection molding production.

Process for Clean Room Injection Molding Production:

Quick response for mold and part quote

Analyzing part design and make a personal solution

Create a professional team of project management

Ordering steel material and start mold processing

Weekly schedule for mold processing

Mold Trial and make samples production

Samples checking and make mold modification

Finish final version samples and mold shipment

If you need any kinds of clean room injection molding, please contact us, as a professional mould part manufacturer, Packson Mold is willing to offer you high quality products.

Other supplier products

|

|

2K Injection Molding |

ISO Class 8 Clean Room

Quality Control

Low & High Volume Manufacturing

Competitive Price

Reliability and Stability

2k inject... |

|

|

Silicone Rubber Injection Molding |

Packson's state-of-the-art facilities consist of a 1000㎡ certified clean room, which is equipped with 14 sets of Liquid Silicone Rubber (LSR) injec... |

|

|

Product Design & Development |

In addition to providing moulding die designsolutions, we can also provide customers with product design optimization solutions to save more cost a... |

|

|

Clean Room Injection |

With more than 20 years of experience in clean room injection molding, as the medical silicone molding companyin China, we specialize in various cl... |

|

|

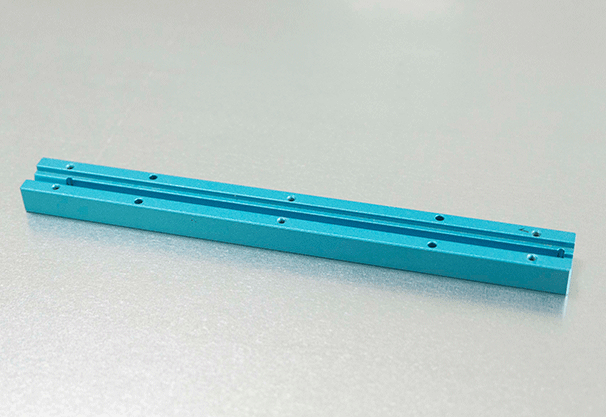

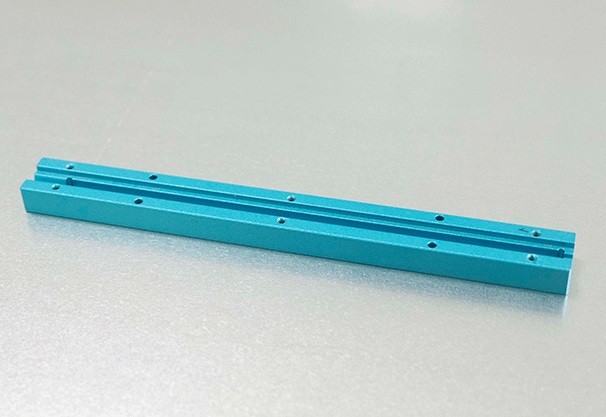

CNC Metal Machining Parts |

Packson is a contract manufacturer specializing in CNC Milling, CNC Turning, CNC Drilling services in China. We are able to manufacture plastic mac... |

供应产品

Same products

|

|

Mold Components |

卖方: Packson Mold Co.,Ltd |

We provide custom made plastic parts-Sliders, inserts, lifters, blocks, ejector pins, and other m... |

|

|

Custom Metal Machining Parts |

卖方: Packson Mold Co.,Ltd |

Packson provides our customers a various CNC machining services to our customers, including milli... |

|

|

Clean Room Injection |

卖方: Packson Mold Co.,Ltd |

Packson - Medial Injection Moulding Cleanroom Expert Packson specializes in delivering top-notch ... |

|

|

Medical Plastic Injection Molding |

卖方: Packson Mold Co.,Ltd |

Packson - Medical Plastic Injection Molding Expert Packson sets itself apart from other medical i... |

|

|

CNC Metal Machining Parts |

卖方: Packson Mold Co.,Ltd |

Packson is a contract manufacturer specializing in CNC Milling, CNC Turning, CNC Drilling service... |