Horizontal Machining Center

Horizontal Machining Center parts can automatically finish four sides milling, boring, drilling, expanding, reaming, tapping, and other multicoated processes after one clamping. Talk to our engineers, you will find the best solution.

Features of Horizontal Machining Center

This series horizontal boring and milling centeris developed and manufactured in sealion china machine tools. It is advanced and leading products in China for general machining purposes.

The machine is widely used in the processing of box parts, shell parts, disc parts, and special-shaped parts in aerospace, automobile, die, and machinery manufacturing industries. The parts can automatically finish four sides milling, boring, drilling, expanding, reaming, threading, and tapping after one clamp.

How does Horizontal Machining Center Work?

CNC control

Although the machining tasks completed in the horizontal machining center are more complex and critical, through quick and simple settings, sequential commands can be executed through CAD files.

Basic structure

As the name suggests, horizontal machining center uses a main axis parallel to the ground. The horizontally oriented spindle operates the tool extending outward from the side of the tool holder to remove material from the side of the metal part. During the cutting process, metal shavings will be generated and fall off the workbench.

The horizontal machining center rotates the cutting bit against the surface of the stationary workpiece. Unlike operations, turning centers rotate workpieces instead of tools in turning applications. Depending on the application, the cutting tool rotated by the spindle in the HMC can remove material at high speed or slowly and slightly.

Although HMC is suitable for materials such as aluminum, steel, copper and even plastics, the characteristics of the material and the chips generated during the cutting process should be considered to optimize the processing technology and reduce wear.

Milling cutter

The rotating tools of these CNC machining centers for boring milling turningperform high-precision milling and other machining operations along the rotating axis to add additional functions. Speaking of milling cutters or end mills, they are produced with teeth and grooves, and they are sharp cutting edges determined by the contour of the product. The material, helix angle and running speed of the milling cutter are important factors that affect the actual milling performance.

Horizontal Machining Center VS Vertical

Both cnc horizontal turning centersand vertical machining centers are popular metal processing solutions and are widely used in workshops. Two styles with different directions from the main axis have their own advantages. When choosing between the two, the number of sides to be cut and the shape of the product are key. In short, if the product needs to be processed on more than two sides, horizontal machining center will be a better choice than vertical machining center.

Vertical machining center is a more economical choice. If you only want to add features on one side of the part, a solution that requires fewer workpiece fixtures and fixtures can provide simpler and more familiar operations. Vertical machining centers are large enough to handle heavy loads and the largest parts, but they can also be used to machine tiny parts, such as medical bone plates.

As mentioned earlier, horizontal machining centers are more advantageous for applications that require multi-sided machining. The 2 integrated trays that normally hold the fixture allow access to the front and side of the part. This feature eliminates human error and significantly improves productivity. Compared with vertical machining center, another advantage of horizontal machining center is the larger tool magazine tool holder, which can improve the chip flow and can hold up to hundreds of tools.

Advantages of Horizontal Machining Center

High Accuracy-advanced thermal control system with a hollow cooling system.

High Speed-12000rpm top spindle speed, 54000mm/min fast-moving speed.

High rigidity- best HT250 casting for the machine body.

Parameters of Horizontal Machining Center

|

Item |

Unit |

MDH40 |

MDH50 |

MDH65 |

MDH80 |

MDH125 |

|

Table Size |

mm |

400x400 |

500x500 |

630x630 |

800x800 |

1250x1250 |

|

No of Pallet Changer |

2 |

2 |

2 |

2 |

2 |

|

|

Table Type |

IT OP: BRT |

IT OP: BRT |

IT OP: BRT |

IT OP: BRT |

IT OP: BRT |

|

|

90 Degree indexing Time |

S |

5 |

||||

|

Pallet Change Time |

S |

5 |

6 |

12 |

35 |

|

|

Max Load on Table |

Kg |

400 |

800 |

1300 |

2000 |

3000 |

|

X/Y/Z Travel |

mm |

630/620/710 |

780/750/800 |

1050/900/900 |

1400/1100/1050 |

1700/1400/1240 |

|

Table surface to spindle |

mm |

80-700 |

80-830 |

80-980 |

80-1180 |

70-1470 |

|

Table center to Spindle |

mm |

150-860 |

150-950 |

200-1100 |

200-1250 |

360-1600 |

|

Spindle Taper |

ISO40 7:24 |

ISO50 7:24 |

ISO50 7:24 |

ISO50 7:24 |

ISO50 7:24 |

|

|

Max Spindle Speed |

RPM |

10000/12000 |

6000/8000/12000 |

6000/8000/12000 |

4000/8000/12000 |

6000 |

|

X/Y/Z Rapid Speed |

m/min |

60 |

45/54 |

45/54 |

36/45 |

45 |

|

Tool changer |

40/60/80/120 |

40/60/80/120/160 |

40/60/80/120/160 |

40/60/80/120/160 |

40/60/80/120/160 |

|

|

Shank Type |

BT40 |

BT50 |

BT50 |

BT50 |

BT50 |

|

|

Max Tool Length |

mm |

350 |

500 |

500 |

500 |

500 |

|

Max Tool Weight |

Kg |

8 |

25 |

25 |

25 |

25 |

|

Changing Time |

S |

2 |

2 |

|||

|

Positioning Accuracy |

mm |

|||||

|

Repeatability |

mm |

|||||

|

CNC |

Fanuc 31i |

Fanuc 31i |

Fanuc 31i |

Fanuc 31i |

Fanuc 31i |

|

|

Dimension |

mm |

2495x5855x2771 |

3200x4891x3125 |

5145x3342x4305 |

5960x3682x3827 |

8075x6087x3702 |

|

Weight |

Kg |

8000 |

15000 |

18000 |

24500 |

32500 |

As one of cnc horizontal machining center suppliers, we can offer sorts of cnc horizontal machining center for sale, if you have needs, please contact us.

If you are looking for a reliable machining center manufacturer, please choose us, and we will be your best partner.

在线联系供应商

Other supplier products

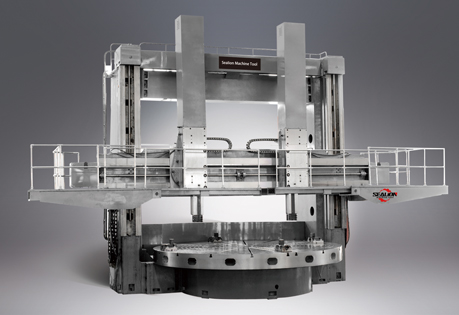

| 2-Axis CNC Double Column Vertical Lathe | 2-Axis CNC Double Column Vertical Lathe is compatible with automatic tool change system (ATC) and ATC as well as complex machining functions. Rega... | |

| Horizontal Lathe | As a professional horizontal lathe manufacturerand horizontal lathe supplier, Sealion Machine Tool supplies a wide range of horizontal lathe machin... | |

| Slant Bed CNC Lathe | Slant bed cnc lathe machineare available on this series of machines, multiple processes including turning, milling, boring, drilling, counterboring... | |

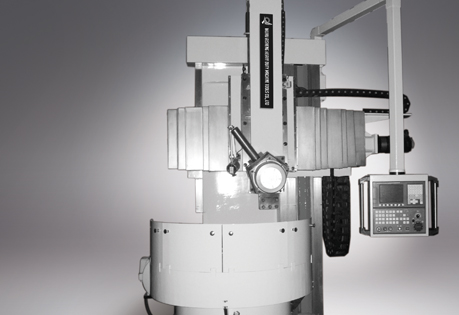

| Single Column Vertical Lathe | Conventional Single Column Vertical Lathe Servo motor and gearbox directly drive the Ballscrew for X&Z axis feeding. It makes the machine bette... | |

| Floor Type Boring Mill | Floor type 5 axis milling machine is suitable for large size jobs to do milling, boring, drilling, etc. The floor type boring and milling machine i... |

Same products

| The Ultimate Tool for Bubble-Free Displays | 卖方: 深圳市维客修科技有限公司 | FORWARD FW-16R除泡机、FW-8R迷你除泡机,在手机、iPhone、iPad、平板屏幕翻新过程中,去除屏幕OCA气泡,最大支持12.9寸屏幕。安全门设计,24V低压风阀配置,有效降低... | |

| Precision CNC Lathe With Conjoined Oblique Rail Cutter Tower | 卖方: Zhejiang Guoyu CNC Machine Tool Co., Ltd. | Technical Characteristics: 45° slant bed base structure, with strict aging treatment, smooth ... | |

| Rail Welder A Frame aligners railway welding tools | 卖方: 834406 | 产品描述 A型车架 A-Frame 是一种导轨对准器,可精确对准要焊接的导轨。该设备在焊接操作期间将导轨固定到位。 | |

| 2 parts fluid mixing dispenser 2 component dosing epoxy PU silicon rubber vacuum system | 卖方: 824681 | What is the difference between 2K AB adhesive materials manual potting machine and robot pottingm... | |

| Horizontal Machining Center | 卖方: Xilong (Shanghai) Machine Tool Co., Ltd. | Horizontal Machining Center parts can automatically finish four sides milling, boring, drilling, ... |