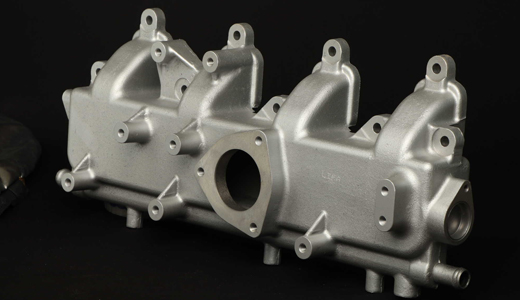

Resin Sand Casting

Resin sand castingis a kind of floor molding process, by mixing the resin with quartz sand and solidification agent, to create the very hard and solid mold. The resulted resin sand casting product will have smooth surfaces, accurate dimensions, and less sand residual and casting defects on the surfaces or inside. During the resin sand casting process, some annexing agents also shall be applied to improve the intensity of resin sand.

Basic Property of Resin Sand Casting Products

dimension tolerance ±0.3mm, CT5~7;

surface finish Ra5;

wall thickness up to 7mm;

unit weight extent 1~40000kg;

unit size limitation 0.03~3.5 meter;

degree of complexity- complex;

machining required- normal;

production lead time- short;

production cost- low.

Advantages Of Resin Sand Casting

Resin sand casting typically produces accurate results that are superior to other sand-casting methods.

This process also results in increased surface strength when compared to other sand-casting options

The nature of resin sand casting can help reduce defects such as sand holes, air holes, and shrinkage.

More flexibility with sizing

Resin sand casting can produce large iron castings. These resin bonded sand castingcan range from dozens of kilograms up to several tons.

Resin Sand Casting Process

Compared with clay sand, the appearance quality of resin sand castings depends on the quality of the mold, thus resin sand requires a higher quality of the mold. The molding process when making it better adapted to the needs of resin sand molding, mainly in the following aspects:

Machining allowance: The hardened resin sand castings have better stiffness and higher dimensional accuracy and are not easily deformed, so when choosing process parameters, a smaller machining allowance can be selected, thus reducing the consumption of metal solution and the cost of machining, which can improve the dimensional accuracy of the castings.

Mold slope: resin sand in the mold has a certain hardening strength, smaller yielding, larger friction if the use of knocking method to start the mold, easy to damage the mold, while the resin sand poor repairability, start the mold if damaged, more difficult to repair. When using resin sand molding, according to the actual production and product structure should increase the mold drawing slope, can smoothly start the mold, get the quality with the market for castings product appearance quality requirements continue to improve, resin sand castings in the quality of the advantages will be increasingly important, resin sand casting production process, will also be rapid development and popularity.

Surface roughness of the mold: the roughness of the mold surface plays a decisive role in the surface roughness of resin sand castings, thus minimizing the surface roughness of the mold is an important measure to obtain high-quality castings.

Raw Materials of Resin Sand Casting

The correct choice of raw materials is the basis for reducing the cost of resin sand casting. The choice of raw materials has a greater impact on resin bonded sand casting cost. Because the raw material is good or bad, on the one hand, affects the number of various materials added and consumed, on the other hand, affects the quality index of the casting.

Selection of raw sand

The original sand is divided into ordinary sand, washed sand, scrubbed sand, and other types because the mud content in the scrubbed sand has been very little, so it can greatly reduce the waste of resin, should be the first choice, followed by washed sand, but never use the original sand without treatment.

Selection of resin

Resin is more expensive and has a greater impact on the casting cost. If you choose a poor quality resin, not only affects the quality of the sand, resulting in more casting scrap but also increases the amount of resin added, the direct result is to make the casting costs increase.

Selection of other raw materials

Other raw materials include curing agents, paint, binder, release agent, sealing clay bar, etc. The impact of these raw materials on the quality of the casting is not the main, but the impact on the cost of casting should not be ignored, such as the amount of curing agent added to the different, not only due to the impact on the productivity of the molding process and affect production costs, but also affect the cost of materials. Therefore, the selection of other raw materials principle is to consider both its quality, but also to consider its match with the main materials such as procurement, transportation, and other issues.

Rayforce Manufacture is a private castings company, we provide metal casting china, vacuum die casting, furan sand mouldingand etc. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| Sodium Silicate Sand Casting | Sodium silicate is a generic name for chemical compounds with the formula Na2SiO3. This material is generally colorless transparent solids, or in w... | |

| Vacuum Investment Casting | Vacuum investment castingis one of the precision investment casting methods. This special technic is mainly applying to producing the small but hig... | |

| Vacuum Investment Casting | Vacuum investment casting is one of the precision investment casting methods. This special technic is mainly applying to producing the small but hi... | |

| Agriculture & Vehicle | Rayforce's metal casting can be applied to plough, tractor part, soil cultivation, planting, harvesting, hay making, animal feeding machine, etc. ... | |

| Silica Sol Investment Casting | The silica sol also shares the name of water glass in general, it is used by the meatal casting process as mold adhesive which is mixed with sand a... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | 卖方: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | 卖方: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| 陶瓷型芯注射机 | 卖方: 秦皇岛埃孚科技有限公司 | 陶瓷型芯注射机主要用于形状复杂,高品质、高精度铸件的陶瓷型芯的成型。该设备通过吸收国内外先进制造技术和精铸行业的自身特点,研制开发成功。 合模力:35T-100T | |

| 压蜡机 | 卖方: 秦皇岛埃孚科技有限公司 | 注蜡机用于精密铸造生产中蜡模的制作。合模力最大 :10T-150T | |

| 全自动脱蜡釜 | 卖方: 秦皇岛埃孚科技有限公司 | 脱蜡釜,是精铸生产中的型壳脱蜡专用设备 内腔尺寸: Φ1000×1200mm/ Φ1200×1500mm/ Φ1400×1600mm |