Magnetic Flux Leakage Testing Equipment

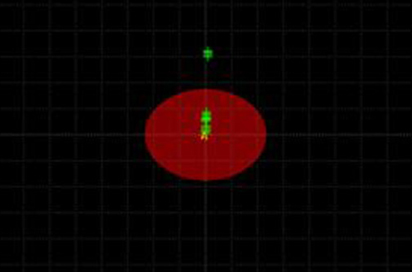

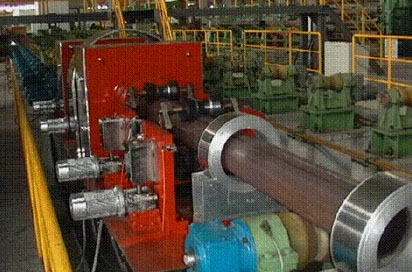

Electromagnetic detection is a very important non-destructive testing method and is widely used. Magnetic flux leakage is a magnetic method of nondestructive testing that is used to detect corrosion and pitting in steel structures, most commonly pipelines and storage tanks. The basic principle is that a powerful magnet is used to magnetize the steel. When used in combination with other methods, it provides a quick and inexpensive assessment of the workpiece of ferromagnetic materials. With the advancement of technology, people are paying more and more attention to the automation of the inspection process. This not only reduces the labor intensity of the inspection work but also improves the reliability of the test results and reduces the influence of human factors. The MFI magnetic flux leakage inspectionmethod is a highly automated magnetic detection technology. The principle is that after the ferromagnetic material is magnetized, the surface and near-surface defects form a leakage magnetic field on the surface of the material, and defects are detected by detecting the leakage magnetic field. In this sense, the magnetic particle detection technology commonly used in pressure vessel inspection. However, it is customary to use the method of measuring the leakage flux with a sensor as the magnetic flux leakage detection, and the magnetic flux to detect the leakage flux. The method is called magnetic particle detection and they are juxtaposed into two detection methods.

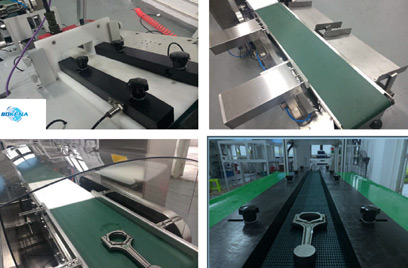

Portable Magnetic Flux Leakage Testing Equipment

Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects on the surface or near surface of the test piece.

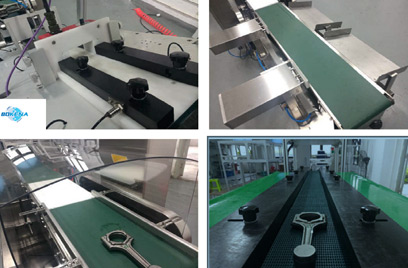

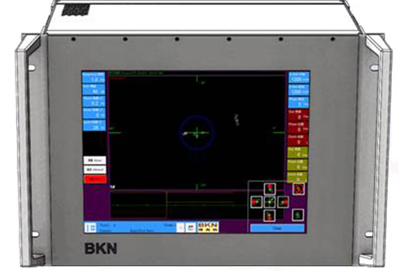

Benchtop Magnetic Flux Leakage TestingEquipment

Magnetic flux leakage testing procedurerefers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects on the surface or near surface of the test piece.

Magnetic particle testing can only detect surface and near-surface crack defects, and it needs surface grinding when testing. It is only suitable for the detection of workpiece discontinuation. In addition to the surface and near-surface crack defects, the MFI magnetic flux leakageinspection can also find the corrosion inside the workpiece from the outside. Defects such as pits, and do not need to be polished on the surface of the workpiece, suitable for on-line inspection of workpieces. On-line inspection of workpieces is currently the most urgent method for users, which can reduce unnecessary parking and reduce inspection costs. In addition, the magnetic flux leakage equipmentcan also quantify the depth and length of defects. Although the application of magnetic flux leakage detection technology is rarely used in workpiece inspection, it has the advantages that magnetic particle detection does not have, so its application prospect is very broad.

As one of the most professional ndt testing equipment suppliersin China, we offer mfl ndt. We welcome merchants from all over the world to cooperate with our factory for mutual benefit and win-win, and jointly create a better future.

在线联系供应商

Other supplier products

| Bolt Eddy Current Sorter BKNFX-11 | Bolt: Mechanical parts, cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external ... | |

| Bolt Vortex Sort BKNFX-11 | Bolt: Mechanical parts, cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external ... | |

| Eddy Current Testing Equipment | Bokena is one of the most professional eddy current test equipment suppliersin China. We have been devoted to produce ect testing equipmentand ect ... | |

| Drill Pipe Magnetic Flux Leakage Detector MFL-308 | Specifications: diameter Φ73 / Φ89 mm, length 9.6m or so Detection speed: 6-20 m / min Acceptance criteria: American Petroleum Instit... | |

| Valve Tappet Eddy Current Flaw Detector QMTZET-04 | Tappet full automatic eddy current testingsystem is a full automatic crack hardness sorter that integrates light, electricity and machinery. The wh... |

Same products

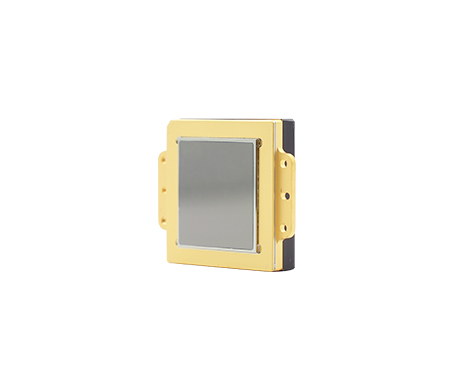

| RTDS121C Ceramic Uncooled Thermal Detector | 卖方: IRay Technology Co., Ltd. | RTDS121C Ceramic Packaged Uncooled Infrared Detector employs a self-developed 12μm uncooled VO... | |

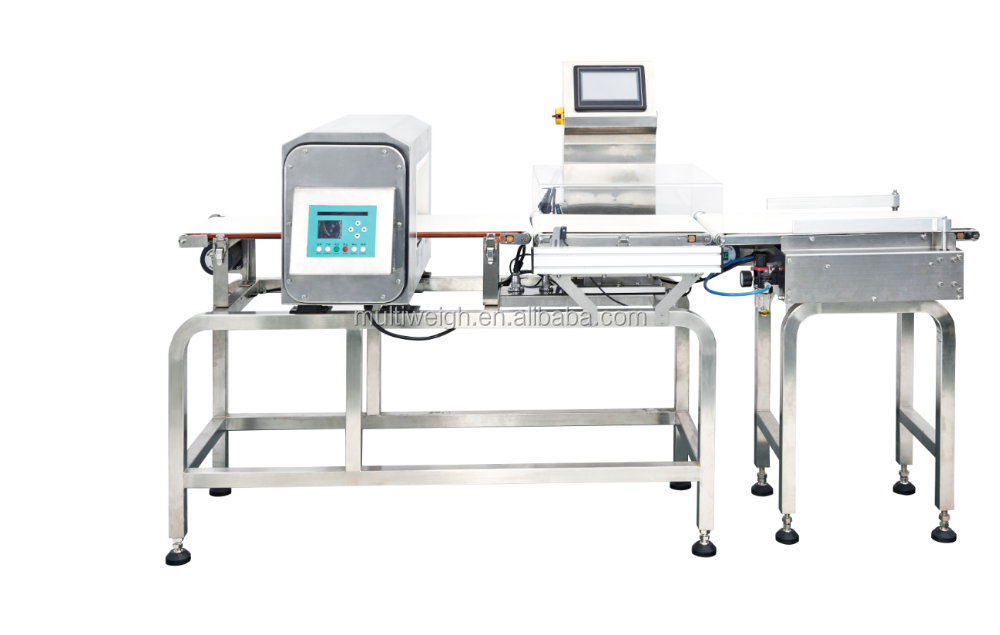

| Combined check weigher and metal detector | 卖方: 广东精威智能机器有限公司 | Mechanical character It combines metal detector with check weigher, and detects the weight and me... | |

| Portable Magnetic Flux Leakage Testing Equipment | 卖方: Nanjing BKN Automation System Co.,LTD | Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of ... | |

| MFL101 Tank Floor MFL Scanner | 卖方: Nanjing BKN Automation System Co.,LTD | Technical Characteristics ofMFL101 Tank Floor MFL Scanner Unique full modular structure, from th... | |

| Magnetic Flux Leakage Testing Equipment | 卖方: Nanjing BKN Automation System Co.,LTD | Electromagnetic detection is a very important non-destructive testing method and is widely used. ... |