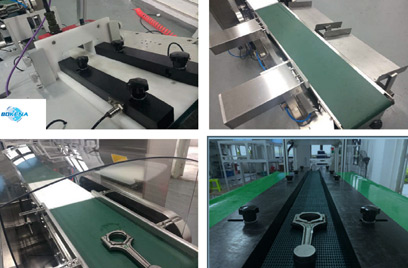

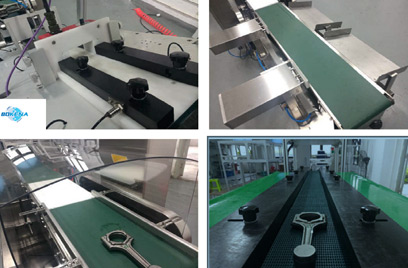

GTET-02 Cylinder Liner Eddy Current Testing Machine

Bokena has eddy current equipment for sale!

GTET-02 Cylinder Liner Eddy Current Testing MachineIntroduction

Detection method

Eddy current testing is to connect the conductor to the coil with alternating current. The alternating magnetic field is established by the coil. The alternating magnetic field passes through the conductor and electromagnetic induction is applied to establish an eddy current in the conductor.

The eddy currents in the conductor also generate their own magnetic field, and the action of the eddy current magnetic field changes the strength of the original magnetic field, which in turn causes a change in the coil voltage and impedance.

When a defect occurs on the surface or near-surface of the conductor, the intensity and distribution of the eddy current will be affected. The change of the eddy current causes a change in the voltage and impedance of the detecting coil. According to this change, the existence of the defect in the conductor can be indirectly known.

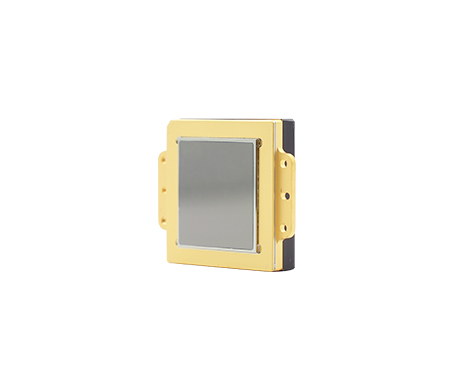

Since the shape of the test piece is different and the detection position is different, the shape of the test coil is different from that of the test piece. In order to meet various testing needs, various detection coils and eddy current testing instruments have been designed.

In eddy current testing, the detection coil is used to establish an alternating magnetic field; the energy is transmitted to the conductor to be inspected, and the alternating magnetic field established by the eddy current is used to obtain the quality information in the detected conductor. Therefore, the detection coil is a transducer.

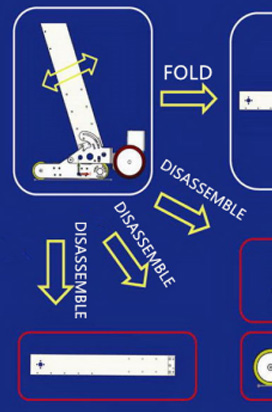

The shape, size and technical parameters of the test coil are critical to the final inspection. In eddy current testing, the type of detection coil is often selected according to the shape, size, material, and quality requirements (testing standards) to be detected. There are three types of commonly used detection coils.

1) Through coil

The through the coil is a coil that detects the sample to be tested and put it in the coil and is suitable for flaw detection of tubes, rods, and wires. Since the magnetic field generated by the coil acts first on the outer wall of the sample, the effect of detecting the outer wall defect is good, and the detection of the inner wall defect is performed by the penetration. In general, the detection sensitivity of the inner wall defect is lower than that of the outer wall. The drawback of thick-walled tubing is that it cannot be detected using an externally wound coil.

2) Interpolated coil

The interposer coil is a coil placed inside the tube for inspection. It is used to inspect the defects of thick walls or the inner walls of the borehole. It is also used to check the quality of the tubes in the complete equipment, such as the in-service inspection of heat exchanger tubes.

3) Probe coil

The probe coil is a coil placed on the surface of the sample for inspection. It is not only suitable for surface scanning inspection of simple plates, slabs, billets, round billets, bars and large diameter pipes, but also for complex shapes. Inspection of mechanical parts. Compared with the through the coil, the probe coil is suitable for detecting small surface defects due to its small volume and small field action range.

As one of the most professional ndt testing equipment suppliersin China, we offer mfl ndt. We welcome merchants from all over the world to cooperate with our factory for mutual benefit and win-win, and jointly create a better future.

在线联系供应商

Other supplier products

| Eddy Current Testing Equipment | Automatic EDM Notchis the ideal equipment for processing artificial defects of pipe rod standards in non-destructive testing work. The flaw detecto... | |

| MFL101 Tank Floor MFL Scanner | Technical Characteristics of MFL101 MFL Tank Floor Scanner Unique full modular structure, from the main body of the computer mechanism the handle ... | |

| BKNFX Pre-Multi-Frequency Eddy Current Hardness Separator | Stimulating the coil makes a magnetic induction to the tested material. The induced electromotive force received by the testing coil is related to ... | |

| Eddy Current Testing Equipment | ECT Eddy current testing is a non-contact testing method, which mainly uses the electromagnetic field and electromagnetic induction between metals ... | |

| MFL101 Tank Floor MFL Scanner | Technical Characteristics of MFL101 mfl tank floor inspection The mfl tank floor scannerhas a unique full modular structure, from the main body of... |

Same products

| RTDS121C Ceramic Uncooled Thermal Detector | 卖方: IRay Technology Co., Ltd. | RTDS121C Ceramic Packaged Uncooled Infrared Detector employs a self-developed 12μm uncooled VO... | |

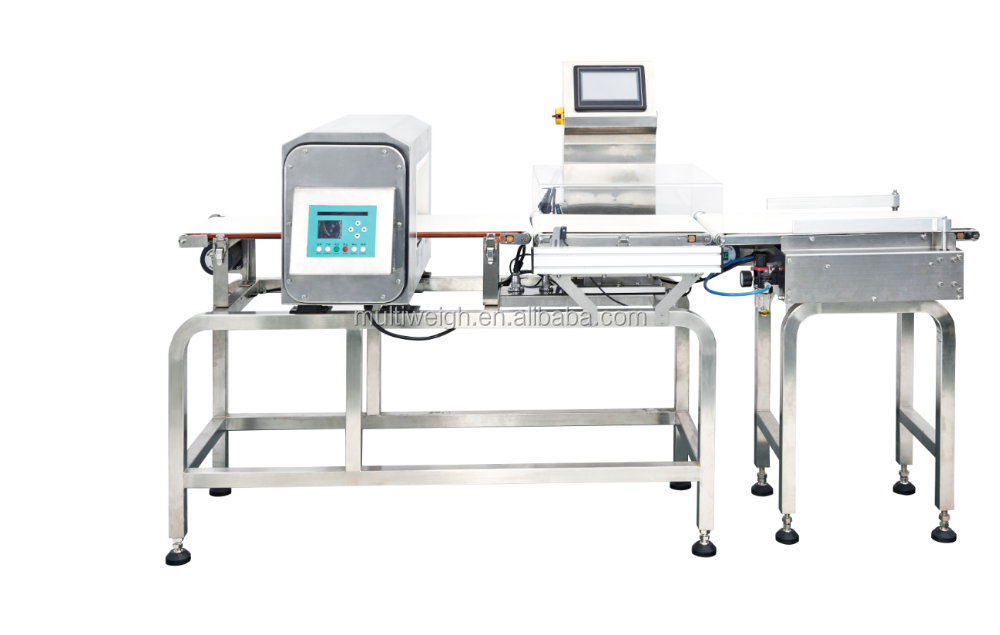

| Combined check weigher and metal detector | 卖方: 广东精威智能机器有限公司 | Mechanical character It combines metal detector with check weigher, and detects the weight and me... | |

| Portable Magnetic Flux Leakage Testing Equipment | 卖方: Nanjing BKN Automation System Co.,LTD | Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of ... | |

| MFL101 Tank Floor MFL Scanner | 卖方: Nanjing BKN Automation System Co.,LTD | Technical Characteristics ofMFL101 Tank Floor MFL Scanner Unique full modular structure, from th... | |

| Magnetic Flux Leakage Testing Equipment | 卖方: Nanjing BKN Automation System Co.,LTD | Electromagnetic detection is a very important non-destructive testing method and is widely used. ... |