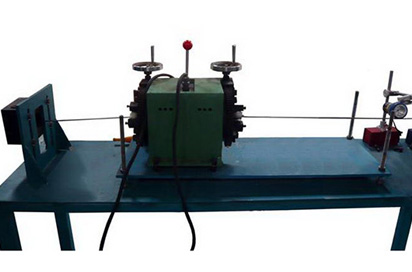

Eddy Current Testing Equipment

Automatic EDM Notchis the ideal equipment for processing artificial defects of pipe rod standards in non-destructive testing work. The flaw detector has the characteristics of simple operation, safety and reliability, high production precision, fast processing speed, and convenient carrying by ultrasonic flaw detection. It can process artificial defects on non-ferrous metals and ferrous metal tubes and bar standards. Hardness sorting can process longitudinal, transverse, and oblique rectangular groove injuries on the inner and outer surfaces of the tube and rod. The core part of the equipment adopts advanced digital processing technology and system integration technology. With modern advanced digital control and servo technology, the injury process is fully automated, with high processing precision, fast speed, easy operation and performance at the international advanced level. The entire instrument is portable and easy to carry and has low requirements for the environment of steel pipe scratching.

How electronic fence works

After the pulse generator (main unit) is energized, the transmitting port sends a pulse voltage to the front fence. The time interval is about 1.5 seconds, and the pulse stays on the fence for about 0.1 second. After the loop is formed on the front fence, the pulse is returned to the host for reception. Port, this port receives the feedback pulse signal; the host also detects the resistance between the two transmitters. If the front fence is broken and the circuit is broken or shorted, the receiving port of the pulse host can not receive the pulse signal or the resistance between the two transmitters is too small, the host will issue an alarm.

Fence alarm

Through the working principle of the electronic fence, no matter what voltage working state the pulse host is in, when the fence is damaged, the receiving port can not receive the pulse signal, the pulse host will alarm; similarly, when the two electronic cables are short-circuited When the resistance is very small, the pulse master will also alarm.

Nanjing BOKENA Automation System Co., Ltd., originated from the eddy current testing laboratory of the Nanjing University of Technology. It isone of the most professional ndt testing equipment suppliersin China. We sincerely invite and welcome people from all around the world to invest and create more values together.

在线联系供应商

Other supplier products

| RQ-120-B Automatic CNC EDM Notch | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKN Automation System Co., Ltd. for maki... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Non destructive weld testing equipment is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise ... | |

| GSET-551 Steel Wire Eddy Current Flaw Detector | GSET-551 Steel Wire Eddy Current Flaw Detector Brief Introduction Using the eddy current signal processing method and high-performance DSP algori... | |

| Eddy Current Testing for Auto Parts | NDTApplication: Eddy current hardness testingtechnology has been widely used in the detection of metal components in the automotive The eddy cur... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | The technology of BKN originated from eddy current Laboratory of Institute of Materials, Nanjing University of Technology. At present, it is a lead... |

Same products

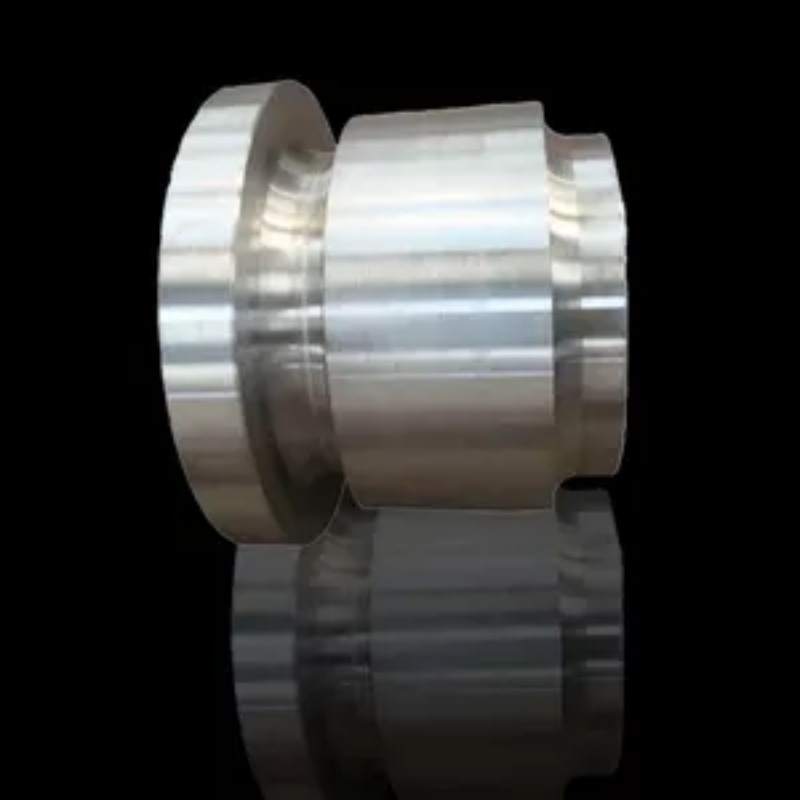

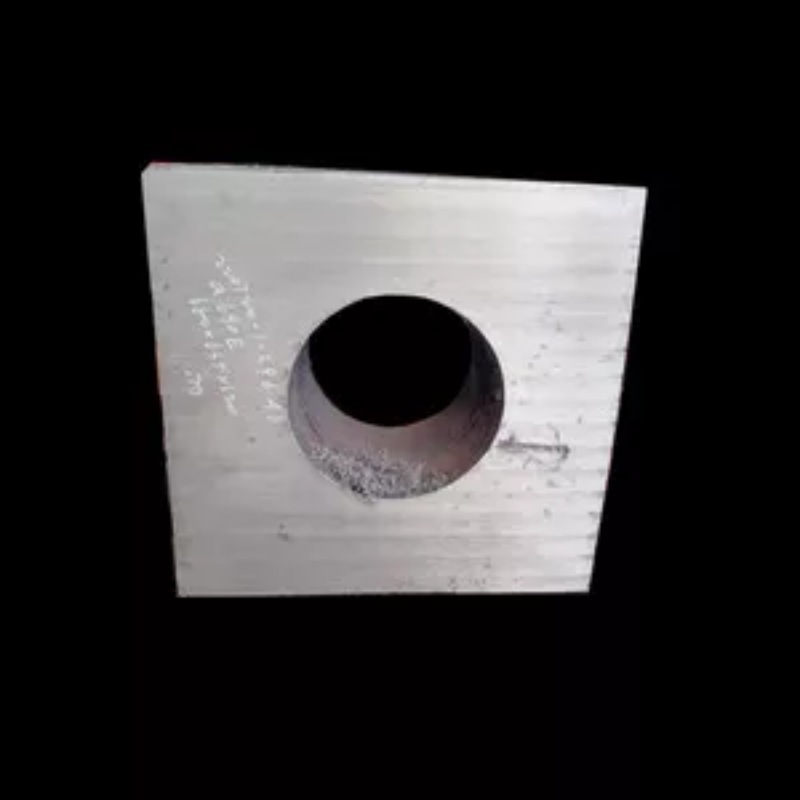

| Drum Forging | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Drum Forging Drum Forging Brand origin: Runchi shandong Processing ability: turning, milling, pla... | |

| Wheel Hub Forging | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Wheel Hub Forging Wheel Hub Forging Main features: [Manufacturing Standards] Strictly produce for... | |

| Nozzle Forging Nozzle | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Nozzle Forging Nozzle Forging Brand origin: Runchi shandong Processing ability: turning, milling,... | |

| Marine Forging | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Marine Forging Marine ForgingMain features: [Manufacturing Standards] Strictly produce custom f... | |

| Bearing Housing | 卖方: Shandong Runchi Machinery Technology Co., Ltd | Bearing Housing Product Name: Bearing housingBrand origin: Runchi shandong Processing ability: ... |