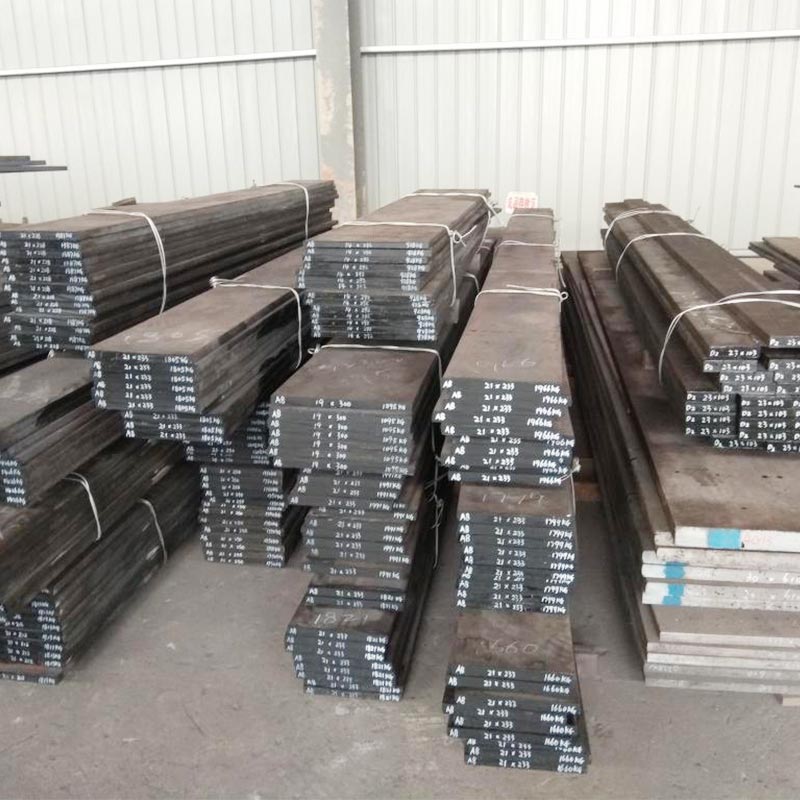

45CrNi4Mo/1.2767 Hot Work Tool Steel Plates Bars Sheet Forgings

Product Details

Chemical composition

|

C |

Mn |

Si |

Cr |

V |

Mo |

P |

S |

|

- |

≤0.03 |

≤0.03 |

Equivalent grades:

|

DIN |

AFNOR |

JIS |

BS |

SIAU |

GB,YB |

|

|

X45NiCrMo4 |

Y35NCD16 |

- |

- |

- |

45CrNi4Mo |

Applicationcharacterized by high level harden-ability and toughness. Suitable for the fabrication of tools exposed to repeated impacts and strong pressure in service. Treated for maximum hardness, it can also be used to construct cold work dies for cutlery, jewelry and plastic, anvils for hammers, rams and pile drivers dies and punches for horizontal forging machines rolls for hot work bending machines. It is advisable to use the blocks for dies treated at various hardness limits according to the etching depth complying with the indications given below.

Heat treatment:

Isothermal annealing:

- Heat to 880°C, hold at temperature for 1/2 h to 1 h;

- Furnace cooling to 610°Cand hold at temperature for at least 30 hours;

- Cool by 10°C/h to 580°C;

- Cooling in air.

Following isothermal annealing with sub-critical annealing, holding at temperature for 10-12 hours, maximum. Softening is obtained with HB<270

Stress relieving:

To be carried out after maching and before the final heat treatment.

- Heat to 630°C, hold for 4-6 hours;

- Furnace cooling to 300-350°C;

- Cooling in air.

Hardening:

- Initial preheating to 350-450°C;

- Second preheating to 650-750°C;

- Heat to hardening temperature in the range 850-880°C and hold at temperature;

- Accrording to the shape and dimensions of the tool, cooling in still or forced air, possibly, in oil or in salt bath at 450-500°C;

in the latter case, as soon as the temperature of the tool is even, continue cooling in air.

Quenched hardness:54-57 HRC.

Tempering:

In the range 550-630°C for 4-6 hours according to the hardness required, the dimensions of the parts and preating conditions, cooling in still air.

Before tempering, preheat the parts to 200-300°C.

,based on the over one hundred years’s production history of in Huangshi, provide professional services and material for cutting tool companies, mould companies and other industrial enterprises all over the world for years.

在线联系供应商

Other supplier products

| Air-hardening A8 Mod Cold Work Tool Steel Plates Bars Sheet Forgings | Product Details A8 is an air-hardening cold work tool steel. It exhibits good wearing qualities with excellent toughness characteristics. It is we... | |

| GCr15/52100/SUJ2 High-carbon chromium alloy steel Bearing Steel Plates | GCr15 is a high-carbon chromium alloy steel, for its versatility, is used in a variety of mechanical applications. In the annealed condition this ... | |

| Cr12Mov Cold Work Tool Steel Plates Bars Sheet Forgings | Used to manufacturing all kinds of moulds and tools with comparatively larger cross sections and complex shapes, which can bear heavy shock loads.... | |

| 45CrNi4Mo/1.2767 Hot Work Tool Steel Plates Bars Sheet Forgings | Product Details Chemical composition C Mn Si Cr V Mo P S - ≤0.03 ≤0.03 Equivalent grades: DIN AFNO... | |

| S5 Cold Work Tool Steel Plates Bars Sheet Forgings | Preheating: Heat at a rate not exceeding 400°F per hour (222°C per hour). For complex and large tools, heat to 1150-1250°F (621-677&de... |

Same products

| CK800 Flat Bed Lathe | 卖方: Taizhou Eastern CNC Technology Co., Ltd. | The CK800 Flat Bed Lathe carriage in the machine tool adopts a double tool holder design, which i... | |

| stainless steel filter elements | 卖方: ZHUAN LV FILTRATION | stainless steel filter elements Stainless Steel Filter Cartridges/Elements Stainless Stee... | |

| Stainless Steel Banding Strap Strip for Pole Clamp | 卖方: Nanjing Suntay Steel Co., Ltd | Stainless Steel strappingis ideal for cable and pipe banding applications that require various bu... | |

| Aluminum Clad Steel Wire | 卖方: Nanjing Suntay Steel Co., Ltd | Typical Application:Power line crossing water, Power line in industrial ,semi-industrial or coast... | |

| Steel Wire Rope For Wind Power Generation | 卖方: Nanjing Suntay Steel Co., Ltd | Steel wire rope for wind power generationis a high-performance produtc specially designed and man... |