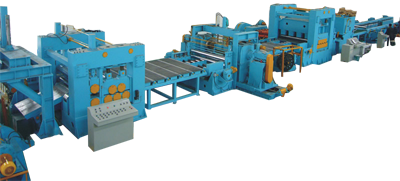

Steel Slitting Line/Machine

Based on much experiences on providing quality, cost-effective and long lasting roll forming systems

Operating Procedure of Steel Slitting Line Machine

Preparatory work before steel slitting machine production

1. Before the formal production, the dust and dirt and other foreign matter on the surface of the equipment and the coil should be carefully cleaned to keep the equipment and the ground floor and articles clean. At the same time, all rollers on the guide road which the strip passes should be carefully cleaned. When necessary, it needs to be polished with sandpaper and then wiped clean with alcohol to ensure that the surface of the finished product is free from scratch and other defects caused by this process.

2. Check the mechanical and electrical system of thesteel slitting equipmentaccording to the equipment inspection table, and operate the equipment in an empty state to confirm that the equipment is in a normal and power-on state.

3. Check whether the production card is consistent with the batch number, alloy status, specification size and weight of the material coil; According to the quality and acceptance criteria of steel slitting linemachine, check whether the surface quality and end face quality of the pending coil meet the needs of production. Before starting the equipment, the crew must comply with the requirements for machine maintenance and operation. After carefully checking all parts of the body, they can send electricity, otherwise they are not allowed to start the equipment.

4. The blanks and finished products parameters are correctly input in the control procedures of the main operation console of the equipment, such as incoming material thickness, incoming width, finished product width, and finished product length. According to the width of incoming material and finished product, calculate the required cutting width and adjust the tool distance. Meanwhile, the number of pieces per stack is calculated according to the requirement of production card.

Matters needing attention in production

1. Be careful not to touch the coil when feeding.

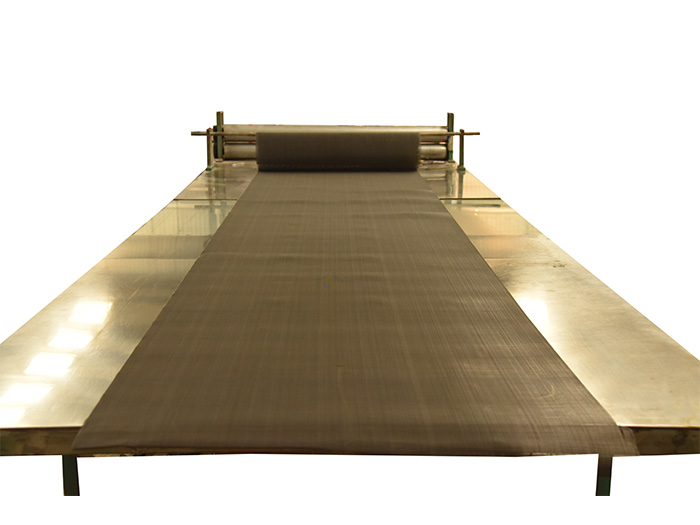

2. Manually adjust the coils on the uncoiler. Normally, the coil must be aligned to ensure that the width of the two cut edges is as consistent as possible. In special cases, when there is a large crack or other defect on the side of the material, the width of the two cutting edge is not consistent, but the horizontal position of the coil on the uncoiler must be adjusted manually, and it is confirmed that the edge defect of the blank can be completely removed.

3. Check the thickness and width of incoming material before production can be carried out.

4. When the material coil with a thickness of more than 0.5mm is removed from the steel belt, the roller must be used to prevent the coil from being thrown.

5. The material should be positive when wearing, and the material should not be crooked or wrinkled. It is strictly prohibited to wipe the rollers at the entrance to avoid getting involved.

6. In the process of cutting slitting machine steel , when marks and scratches caused by the machine are found on the surface of the plate, the guide rollers on the guide road should be stopped and checked timely. If any prominent particles are found, they should be polished with sandpaper and then cleaned with alcohol.

7. Pay close attention to the surface quality of incoming materials during the operation of the machine. According to the requirements of the quality and acceptance standard of steel slitting linemachine, if it is found to be unqualified, it must stop the machine and find relevant technical quality personnel to deal with it.

8. Before each roll of material is produced, a sheet of material should be cut, and the production can be carried out in accordance with the technological requirements of the length and width on the card. If not, it is necessary to adjust the parameters of scissors, otherwise it is not allowed to continue production.

9. When lifting the finished products, it is necessary to carefully inspect the crane and rigging, and command and operate overhead travelling cranes to concentrate. Operators are prohibited from standing in small and unsafe places to prevent material from swinging.

10. In case of equipment failure in production, stop immediately and inform the maintenance staff to deal with it.RISHBIN, one of the best steel slitting machine manufacturers with the high-qualitysteel slitting lines, was founded in 1999. With almost twenty years development, it has become a leading steel slitting company in this field and exports its quality slitting machine for steel and other materials to the world. RISHBIN is dedicated to providing quality services and quality products.

在线联系供应商

Other supplier products

| Steel Slitting Line/Machine | Based on much experiences on providing quality, cost-effective and long lasting roll forming systems Operating Procedure of Steel Slitting Line... | |

| Heavy Gauge Cut To Length Lines | is a high efficient metal processing production line for cutting metal flat sheet from metal coils. The metal coils unwind, leveled, cut to lengt... | |

| Light Gauge Slitting Lines | RISHBIN Light Gauge Slitters for pre-painted/coated coils, max. thickness of up to 3mm, max. width of up to 2200mm, and speed of up to 300 m/min.... | |

| Light Gauge Cut To Length Lines | is a high efficient metal processing production line for cutting metal flat sheet from metal coils. The metal coils unwind, leveled, cut to lengt... | |

| Stainless Steel Slitting Machine | Based on much experiences on providing quality, cost-effective and long lasting roll forming systems Classification and Characteristics of Stainl... |

Same products

| Plain Steel Mesh | 卖方: Hebei Jiushen Wire Weaving Co., Ltd | Plain steel wire meshis a kind of wire mesh that woven from various kinds of carbon steel wires. ... | |

| 18650 Nickel Strip Phone Battery Spot Welding Connector Sheet | 卖方: 深圳市维客修科技有限公司 | Description 3GOA high purity 18650 battery nickel strip lithium battery connector 1M 5M ... | |

| 第二十六届广州国际不锈钢工业展 | 卖方: 广州巨浪展览策划有限公司 | 第二十六届广州国际不锈钢工业展 邀请函 主管批准单位: 中华人民共和国商务部外贸司 广东省对外贸易经济合作厅 主办承办单位: 广州巨浪展览策划有限公司 协办单位: 天津市... | |

| Centrifugally cast Chromium-Nickel alloy tubes | 卖方: Nanjing Xinshuo Mechanical Equipment Co., Ltd. | Centrifugally cast Chromium-Nickel straight alloy tubes | |

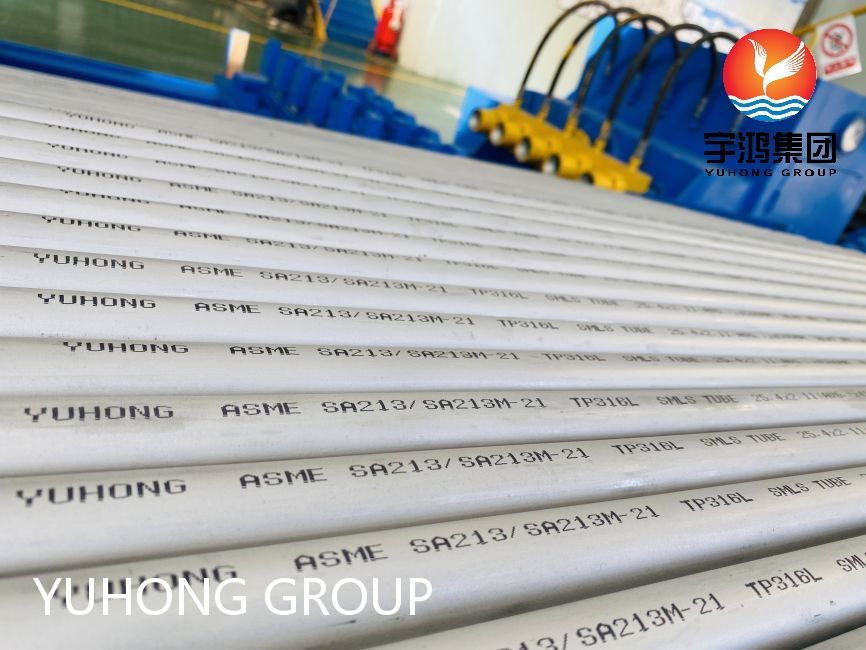

| STAINLESS STEEL PIPE/TUBE | 卖方: YUHONG GROUP CO., LIMITED ZHEJIANG YUHONGWELL STEEL CO., LIMITED | STAINLESS STEEL PIPE/TUBE Stainless steel pipe/tube is one of the most widely used in manufactur... |