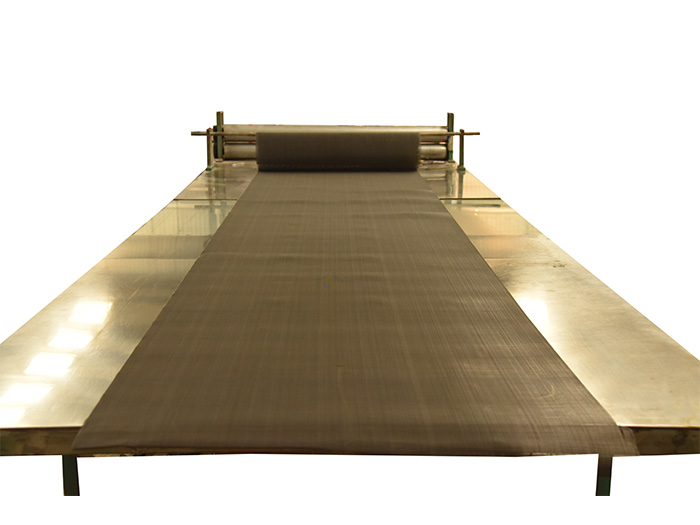

Stainless Steel Slitting Machine

Based on much experiences on providing quality, cost-effective and long lasting roll forming systems

Classification and Characteristics of Stainless Steel Slitting Machine

1. Small(it can be divided into manual steel cutting machine and semi-automatic steel cutting machine)

Small steel cutting machine is the most ideal and convenient sawing machine for cutting metal profiles. It has a wide cutting range, small volume, convenient operation, low noise, no dust, no burrs inside and outside the incision, and features of various angles. The structure is simple, the manufacturing cost is relatively low, so the price is cheaper. The domestic small steel slitting machine can be bought about 20 thousand.

1.Automatic steel slitting machine

Automatic steel cutting machine has three advantages: 1) it can set 5 different cutting lengths and Numbers at the same time without discontinuous cutting; 2) the error of cutting length is within the range of plus or minus 0.1; 3) PLC touch screen control, low speed rotating high-speed hacksaw blades are suitable for cutting various metal pipes without burrs.

Automatic steel slitting machine is the most widely used cutting equipment for all kinds of stainless steel tubes and metal pipes. It can be divided into hydraulic steel slitting machine and servo steel slitting machine, which is a high-precision automatic profile cutting machine.

2.Automatic and intelligent high efficiency steel slitting machine

The size of the automatic intelligent and efficient steel cutting machine can be customized and the production efficiency is high. One person can operate 10 units. When we purchase, we should first choose a steel cutting machine produced by a manufacturer with large production scale, stable product quality, perfect after-sales service system and high reputation. Although the prices of steel cutting machines produced by these manufacturers are higher than those produced in small factories, the quality and after-sales service are much better than those of small factories, and they are more comfortable to use. Even if there are some technical problems in use, it will help you solve them in time. If you buy more kinds and quantities of steel cutting machines, it is better to choose the same manufacturer. In this way, it will be much more convenient for future production, management and maintenance. And because of the bulk purchase, prices and services can be more favorable. If you do not have high requirements on cutting precision, you may consider purchasing a small manual steel cutter, which can save the investment of equipment purchase and is relatively cheap. The advantages of automatic intelligent and efficient steel slitting machine are: automatic feeding, sawing precision, burr free, automatic sizing, high efficiency, intelligence, and no deformation of pipe ends.

Operating procedures

1. Before use, it should be checked and confirmed that the electric motor and cable are normal, the protection grounding is good, the protective device is safe and effective, the saw blade is selected to meet the requirements and the installation is correct.

2. After starting, the sawblade should operate at no load, check and confirm that the sawblade runs in the correct direction, the lifting mechanism is flexible, and there is no abnormal or abnormal noise in the operation. When everything is normal, you can do it.

3. The operator should press the workpiece tightly with both hands and feed evenly. When driving the stainless steel slitting machine, it is not necessary to exert too much force. No gloves are not allowed to operate.

4. The thickness of the cutting shall be carried out according to the nameplate of the mechanical factory, and the cutting shall not be super thick.

5. When the workpiece is sent to a distance of 300mm from the saw blade or small pieces of material are cut, the special tool shall be used to deliver the material, and the material shall not be directly pushed by hand.

6. During the operation, when the workpiece has impact, beat and abnormal sound, the machine should be stopped immediately to check. After troubleshooting, the operator can continue to work.

7. It is strictly prohibited to check and repair the components in theoperation. Scraps on saws and structural saws should be removed in time with special tools. No hand picking or testing should be allowed.8. After operation, the fuselage shall be cleaned, the saw blade shall be dried, residual water from the water tank shall be discharged, the cable wire shall be returned and stored in a dry and ventilated place.As a star in the steel slitting machine manufacturers in China, Rishbin provide you with the bestslitting machineat the best price.High Speed Stainless Steel Slitting Line Video

在线联系供应商

Other supplier products

| Steel Slitting Line/Machine | Based on much experiences on providing quality, cost-effective and long lasting roll forming systems Operating Procedure of Steel Slitting Line... | |

| Light Gauge Cut To Length Lines | is a high efficient metal processing production line for cutting metal flat sheet from metal coils. The metal coils unwind, leveled, cut to lengt... | |

| Stainless Steel Slitting Machine | Based on much experiences on providing quality, cost-effective and long lasting roll forming systems Classification and Characteristics of Stainl... | |

| Heavy Gauge Slitting Lines | RISHBIN Heavy Gauge Slitters are designed to slit high strength heavy gauge materials. Coils max. thickness of up to 20mm, max. width of up to 2500... | |

| Steel Sheet Slitting Machine | Based on much experiences on providing quality, cost-effective and long lasting roll forming systems Metal steel sheet slitting machine main typ... |

Same products

| Plain Steel Mesh | 卖方: Hebei Jiushen Wire Weaving Co., Ltd | Plain steel wire meshis a kind of wire mesh that woven from various kinds of carbon steel wires. ... | |

| 18650 Nickel Strip Phone Battery Spot Welding Connector Sheet | 卖方: 深圳市维客修科技有限公司 | Description 3GOA high purity 18650 battery nickel strip lithium battery connector 1M 5M ... | |

| 第二十六届广州国际不锈钢工业展 | 卖方: 广州巨浪展览策划有限公司 | 第二十六届广州国际不锈钢工业展 邀请函 主管批准单位: 中华人民共和国商务部外贸司 广东省对外贸易经济合作厅 主办承办单位: 广州巨浪展览策划有限公司 协办单位: 天津市... | |

| Centrifugally cast Chromium-Nickel alloy tubes | 卖方: Nanjing Xinshuo Mechanical Equipment Co., Ltd. | Centrifugally cast Chromium-Nickel straight alloy tubes | |

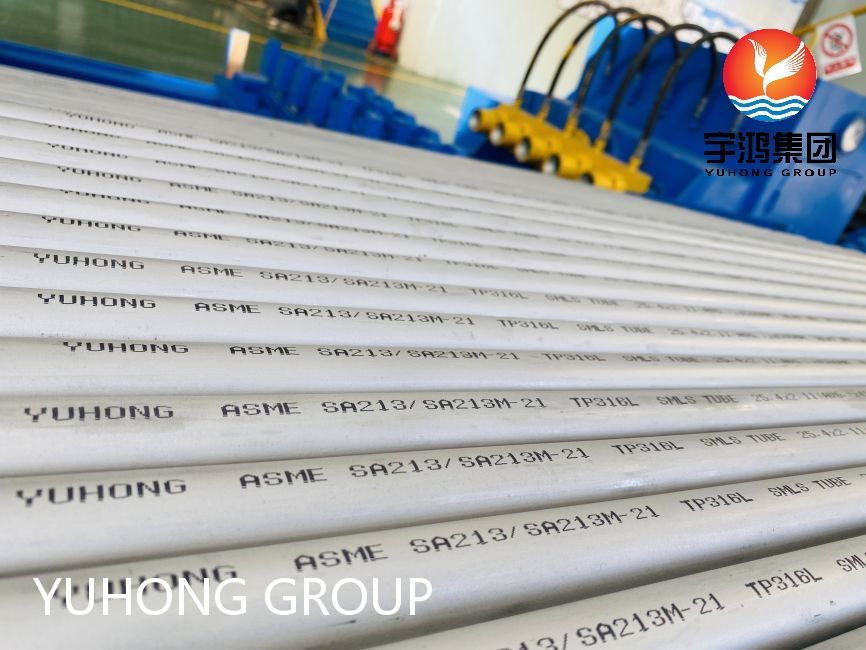

| STAINLESS STEEL PIPE/TUBE | 卖方: YUHONG GROUP CO., LIMITED ZHEJIANG YUHONGWELL STEEL CO., LIMITED | STAINLESS STEEL PIPE/TUBE Stainless steel pipe/tube is one of the most widely used in manufactur... |