Sheet Metal Stamping

Sheet metal stamping (also known as sheet metal pressing and forming) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. We are one of the leading sheet metal stamping suppliers and we have custom sheet metal stamping for you.

What is Sheet Metal Pressing Process

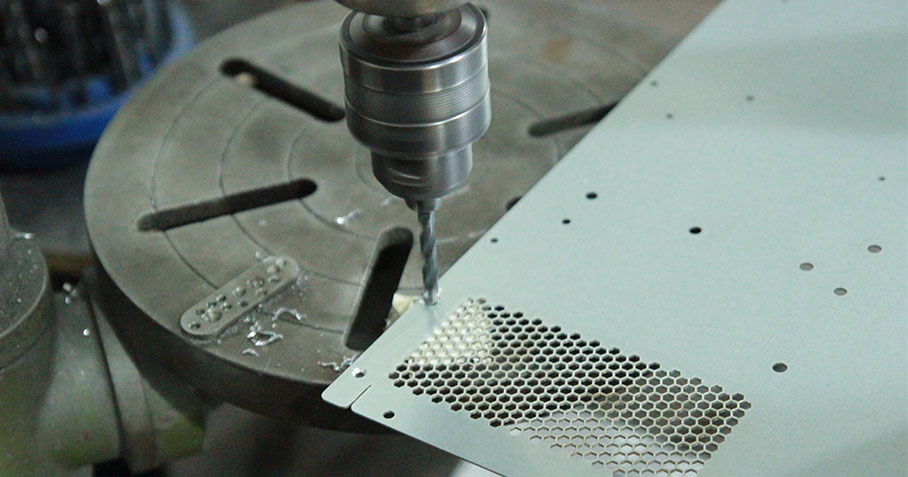

Metal pressing and forming include a variety of sheet metal stamping manufacturing processes, such as punching by using a sheet metal stamping press machine, blanking, embossing, bending, flanging and coining, etc. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part or could occur through a series of stages. The process is usually carried out on sheet metal. During the sheet metal pressings, through using highly specialized computer-aided drafting and manufacturing programs, sheet metal is transformed into complex parts. HSJ has the most professional sheet metal pressings technology which can ensure the high quality of our products.

Custom Sheet Metal Stamping Materials

Metal stamping pressings and dies can work with various metals to diverse parts in HSJ Fabrication's steel stamping factory. Metal pressing and forming material includes SGCC galvanized plate, SECC electrolytic plate, SUS stainless steel (model 201 304 316, etc.), SPCC iron plate, white copper, red copper, AL aluminum plate (model 5052 6061, etc.), SPTE, spring steel, manganese steel. Each metal pressing and forming material has its own advantages.

Benefits of Sheet Metal Stampings

Automakers benefit from the sheet metal pressing for different parts. The dies can be used again to manufacture parts with the same size and shape. All parts are guaranteed to meet strict specifications and tolerances.

Key benefits of our metal pressing and forming include: High quality, Low Cost, long-term durability and Fast Turnaround Time

In HSJ Metal Fabrication, metal pressing and forming can be handled almost entirely by machinery. Not only does this reduce the risk of human error or inconsistency, but it also lowers labor costs.

If you’re an automotive manufacturer looking for sheet metal stamping factory, choose HSJ Metal Fabrication.

Sheet Metal Stampings Equipment

Our state-of-the-art stamping equipment produces precision metal stamping parts quickly and easily, without sacrificing quality. HSJ Metal Fabrication utilizes advanced production equipment to deliver metal stamping parts of high quality, high precision.

Our advanced stamping equipment and technology includes: Quick change tooling, Die conversions, Tool and die making equipment, Press equipment

Sheet Metal Stamping Application

Auto part

We can do the custom sheet metal stamping of the chassis, fuel tank, radiator, boiler steam drum, container casing, motor, electrical iron core silicon steel sheet. Stamping parts for instruments, household appliances, bicycles, office machinery, living utensils, etc. Accuracy can reach 0.05mm, no stain on the surface, etc. For example, auto parts support.

Material: sus304

Surface: Deburring, no scratches.

Process: stamping

Accuracy: ±0.2

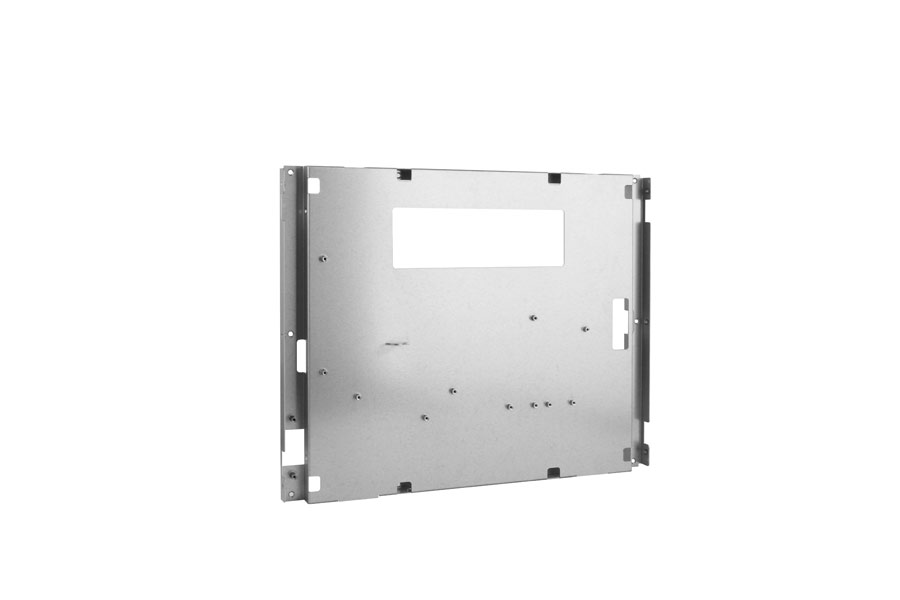

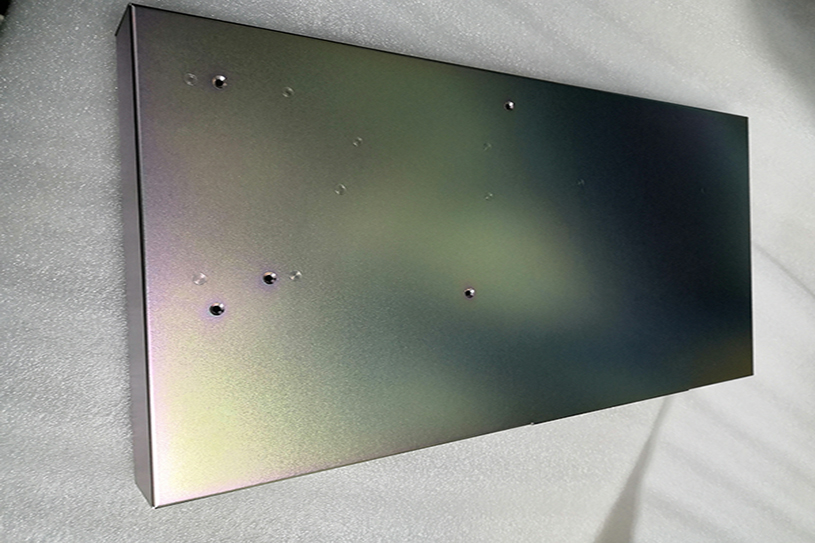

Electronic part

Material: Aluminum 6061-T6

Surface treatments Finish: Steel color

Process: Stamping

Tolerance: +/-0.01mm

We can also manufacture electronic parts box.

There are many sheet metal manufacturing companies, but we are one of the best choices for you.

As one of the most professional china sheet metal forming manufacturers, HSJ Metal Processing has the capabilities meet your needs for CNC steel parts.

Other supplier products

|

|

Stamping Panel Parts |

Detail

Introduction of stamped sheet metal panels

Material: aluminum galvanized sheets(stainless steel, mild steel, steel alloy)

Process: stamping... |

|

|

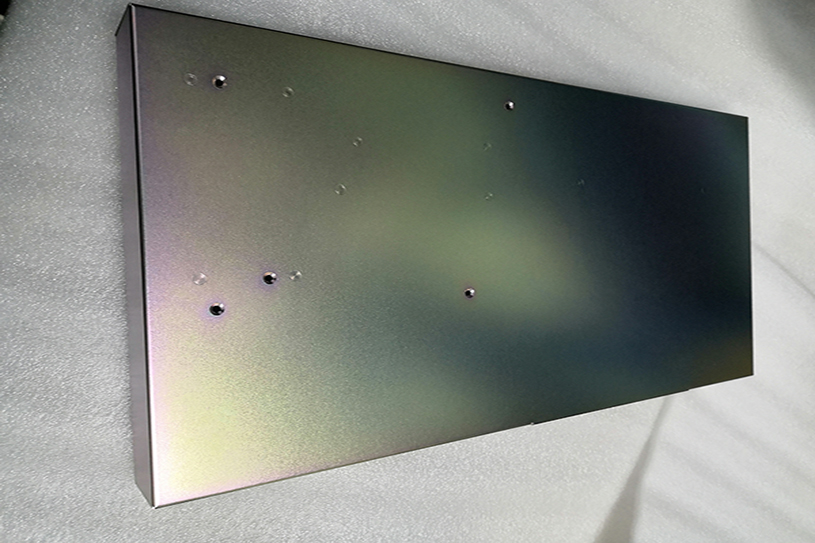

Electroplated & Anodized Enclosure |

Electroplated &Anodized Enclosure

Surface treatment :

anodized(Zinc/Nickel/Chrome/Plated, Spray paint, powder costing etc.)

Material:

sus... |

|

|

CNC Stainless Steel Parts |

Stainless Steel CNC Parts

Material:

sus

Tolerance:

Machining standards: limited linear dimension tolerance ±0.1mm,geometric dimension ... |

|

|

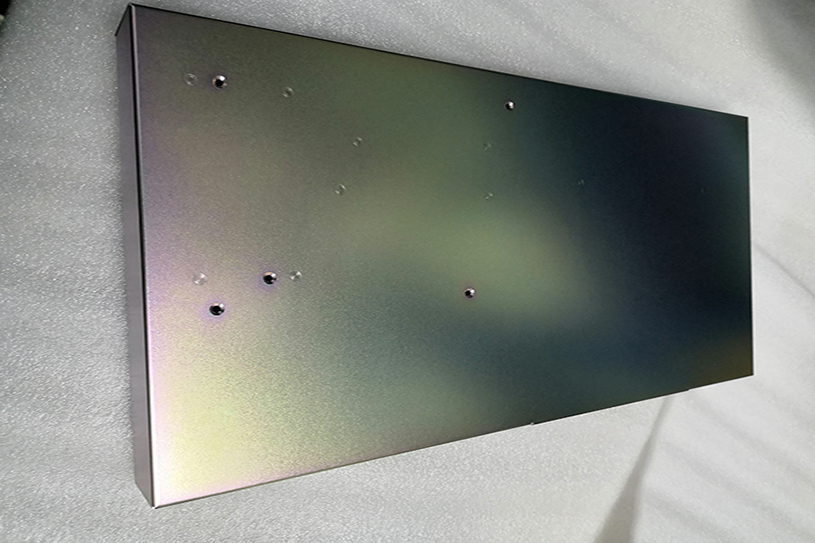

Electroplated & Anodized Enclosure |

Detail

Surface treatment : anodized(Zinc/Nickel/Chrome/Plated, Spray paint, powder costing etc.)

Material: sus/spcc/secc

Tolerance:0.1mm

Engrave... |

|

|

ELECTROPLATED & ANODIZED ENCLOSURE |

Surface treatment : anodized(Zinc/Nickel/Chrome/Plated, Spray paint, powder costing etc.)

Material: sus/spcc/secc

Tolerance:0.1mm

Engraved logo ... |

供应产品

Same products