软管灌装封尾机

CFNY-60A TUBE FILLER SEALER

(applicable to plastic tubes、laminated tubes)

Inner-heating type

Parameters:

Adapt to the maximum tube diameter: 60mm

The maximum volume:1- 250ml

Produce speed: 30-60tube/min

Filling precision:≤+/-1%

The power of machine:1.1kw

Air pressure: 0.4-0.6 Mpa

Features:

1、Tubes can load into station automatically and can be automatically pressed into the tube holder.

2、The elastic tension type tube holder is adoped to guarantee the consistent sealing height.

3、The automatic color mark adjusting systems by stepping driving tube holder is adopted for oval tubes or other special-shaped tubes.

4、Adopt mechanical transmission mode filling system ensuring the stability of loading capacity.

5、Original Swiss LEISTER heater is adopted .

6、The internal wall of tube adopts hot air sealing and the external wall of tube adopts cooling water circulative cooling,which can beautiful sealing effect.

7、The fan (made in Taiwan) is adopted to discharge the poisonous gas produced during the heating outside the room.

8、After the sealing, the wind cooling system is adopted to prevent the heat from being conducted to the ointment.

9、PLC automatic control system.

10、Highly clearl stainless steel frame.

11、The connection of emulsifier、cartoning machine and filling machine can be easily achieved.

12、It is easy to operate between different sizes of tubes.

13、Automatic completion of filling 、sealing and batch No. printing in one machine.

14、Provided such functions as automatic supply of a tube to a worktable of machine、tube color mark automatic adjustment in a holder and automatic filling and sealing.

15、Speed shall be adjustable by inverter.

16、The production capacity can be realized and control automatically.

17、The code mechanical hand print the code automatically in the request position.

18、Human-machine interface with direct display and control.

19、Tube feeding and locating device,which is controlled by the original FESTO vacuum generator.

22、Provided with malfunction alarm,automatic stopping device when mechanical overload.

23、The combined material feeding forms of blow cutting and cutting can guarantee the filling of high viscosity.

24、Column stylel material temperature automatic control blending system.(optional)

25、Ultrasonic hopper level sensor. (optional)

USA BANNER ultrasonic level probe combined with Siemens module can be used to accurately control material level and give direct display on the touch screen

26、No tube no fill.

27、Material pump. (optional)

28、Water cooler(chiller). (optional)

30、 Emergency stop button

在线联系供应商

Other supplier products

| China pharmaceutical machine forTablet laser drilling machine | This JK250-A laser drilling machine used to drill holes in the surface of coating pharmaceutical tablet. Machine data : Capacity(speed) 5000... | |

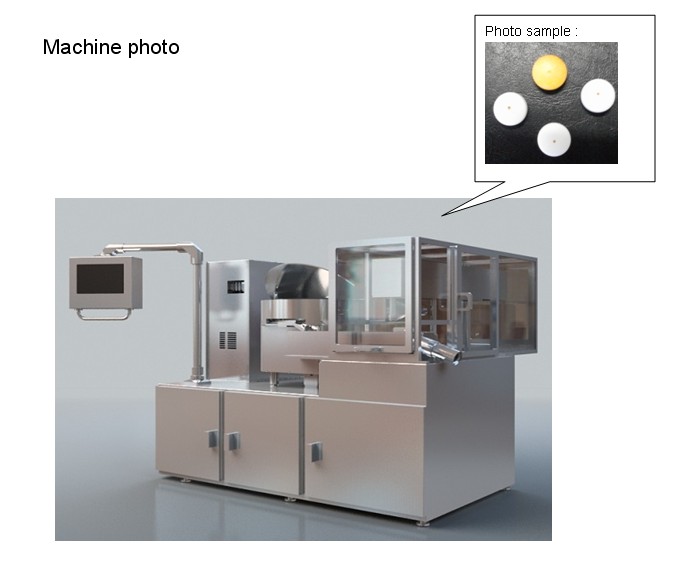

| China pharmaceutical machine forSuppository Production Line (high speed) | GZS-9A-Type High Productive Automation Machine for the Production of Suppository is a new product developed by means of digesting and absorbing for... | |

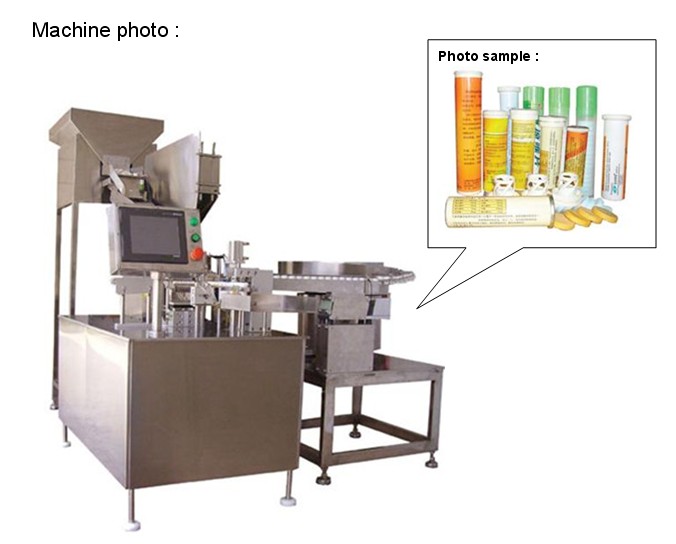

| 泡腾片灌装包装机 | The BSP-40A Tube filling Machine For Tablet is applicable to the packing bigger and thinner tablets which are orderly fed into bobbin bottles in si... | |

| 压片机 | DP-12model single tablet press machine is to absorb advanced technology successfully developed. It is pharmaceutical, laboratory and other industr... | |

| 软管灌装封尾机 | CFNY-60A TUBE FILLER SEALER (applicable to plastic tubes、laminated tubes) Inner-heating type Parameters: Adapt to the maximum tube diameter: 60m... |

Same products

| 拥抱智能自动化,实现无与伦比的纸箱生产效率 | 卖方: cenwan | 我们隆重推出全自动智能高速折盒胶装机,这是现代包装机械设计的巅峰之作。该机器融合了先进的机器人技术、智能传感系统和精密工程,为各种瓦楞纸箱提供真正无需人工干预的生产体验。它旨在最大化您的产出,降... | |

| engraving machine | 卖方: 杭州四色印科技有限公司 | Engraving machine from China, low price and high quality, the machine is very good | |

| 精密雕刻机 | 卖方: 杭州四色印科技有限公司 | 包装机械出口贸易服务,货送到俄罗斯,欧洲,专业客户服务! | |

| Efficient Film Cutting and UV Curing for Your Mobile Devices | 卖方: 深圳市维客修科技有限公司 | Mechanic Auto X450 智能贴膜切割贴合一体机,适用于最大尺寸 12.9 英寸的手机/平板电脑屏幕保护膜的切割、贴合和固化。Mechanic Auto X450 手机/iPhone... | |

| 中国供应商 饮料厂用全自动玻璃瓶果汁液体灌装机 | 卖方: 河北盛辉泵业 | 饮料液体灌装机具有集水处理、清洗、灌装、贴标和封盖于一体的自动化机身,是精确、快速灌装稀薄至中等粘度液体的理想选择。它拥有完善的温度控制系统、自动清洗系统、精确的温度控制系统和逆流系统。 |