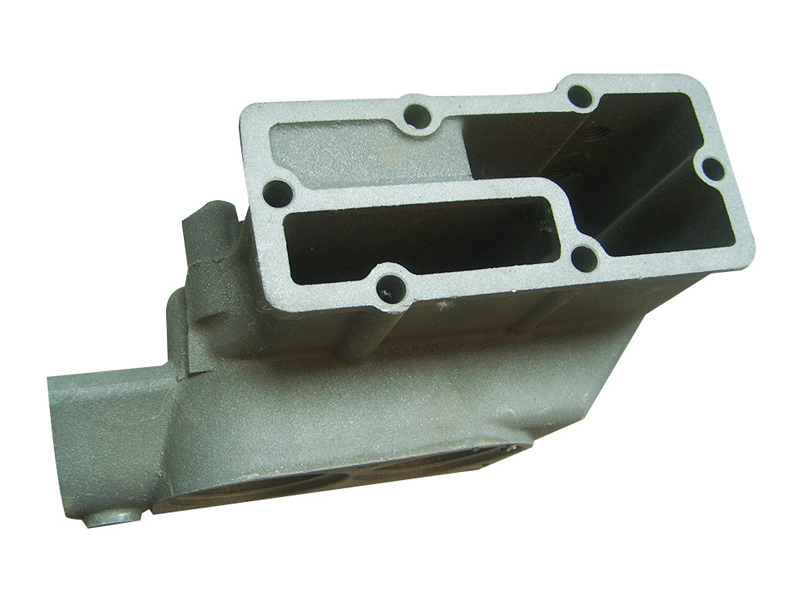

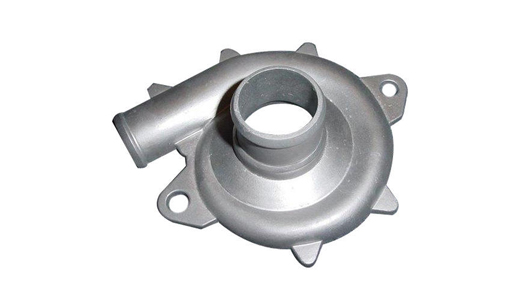

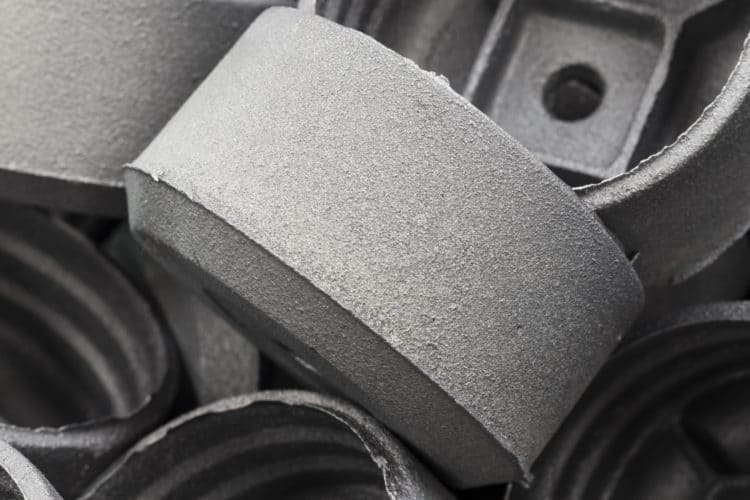

Sodium Silicate Sand Casting

Sodium silicate castingis soluble in water in various amounts. A more common name for sodium silicate is water glass, which is used in iron or steel sand casting. The water glass works as a binder of the sand. It allows the rapid production of a strong Sodium silica sand castingmold, by CO2 through the mixture of sand and sodium silicate in the mold, which hardens it almost instantly. Sodium silicate is a generic name for chemical compounds with the formula Na2SiO3. This material is generally colorless transparent solids, or in white powder, non-toxic and non-inflammable.

Basic Property of Sodium Silicate Casting Product

dimension tolerance ±0.5mm, CT7~8;

surface finish Ra3.2;

wall thickness up to 7mm;

unit weight extent 1~20000kg;

unit size limitation of 0.03~3.5 meter;

degree of complexity- complex;

machining required- normal;

production lead time- short;

production cost- low.

What is sodium silicate Moulding?

Though in most conditions, sodium silicate is one of the types of sand casting and considered to be applied in sodium silicate sand casting. Actually it also could be applied in the sand casting. Besides, sodium silicate sand casting is more suitable to make large and complex structures with an even better surface finish and fewer defects.

Principle of Sodium Silicate Casting

The principle of sodium silicate sand casting and the detailed steps:

Melt the glass and mold it through the mold.

Generally, realize that after the sodium silicate casting mold is made.

The glass melt is injected into the sodium silicate casting mold or realizes that the pre-made mold is stacked with glass scrap in the mold.

Put into the furnace together with the mold for melting.

Anneal the sodium silicate sand casting mold with the glass domain anastomosis after molding.

As a professional casting manufacturing company,We provide sodium silicate casting, sodium silicate sand casting, silica sand casting, etc. Want to know more, contact us.

在线联系供应商

Other supplier products

| Brass,Bronze,Copper Casting | As defined by its main properties, copper offers excellent electrical and heat conductivity, and good corrosion resistance ability as well. But nat... | |

| Compressors & Gears | Rayforce's metal die casting gearscan be applied to Turbo blowers, air control components, piston compressors, casting gears, etc. Application o... | |

| Metal Casting | Casting process usually refers to the metal casting process, is one of heating processing technologies handled by humans can be found recorded as e... | |

| Stainless Steel Investment Casting | The stainless steel has much better physical properties then iron and normal steel, but it possesses worse casting properties. Because the stainles... | |

| Low Pressure Die Casting | The low pressure die casting is to let the melted metal flow into the casting mold under a certain degree of pressure, and solidify the casting par... |

Same products

| ENGINE BRACKET/ENGINE MOUNTING BRACKET | 卖方: EMP Tech Co.,Ltd | car engine mounting bracket engine bracket carwhich is divided into two parts is a component... | |

| ENGINE CYLINDER LOWER BLOCK | 卖方: EMP Tech Co.,Ltd | The car cylinder blockis located between the engine cylinder and the oil pan. EMP Tech, as an ... | |

| 湿砂造型线 | 卖方: China most professional Foundry Machinery platform | 可根据铸件产品定制湿砂(湿砂)砂回收系统 粘土砂是以粘土为结合剂的型砂。 砂处理部是铸造厂的重要组成部分。 其主要任务是为造型制芯部门提供合格的型砂。 型砂的制备直接影响铸件生产质量、产量的提高... | |

| Sodium Silicate Sand Casting | 卖方: Shanxi Rayforce Manufacture Co., Ltd. | Sodium silicate castingis soluble in water in various amounts. A more common name for sodium sili... | |

| Grey Cast Iron Casting | 卖方: Shanxi Rayforce Manufacture Co., Ltd. | The name grey iron is because of the gray color of the fracture it forms, which is due to the pre... |