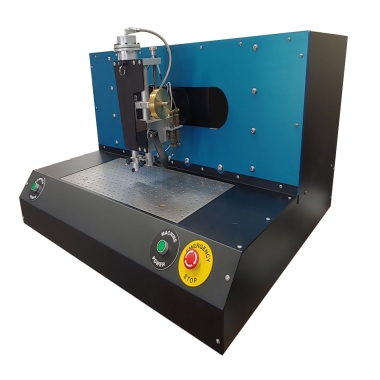

Hydrostatic Head Testing Equipment | Hydrostatic Head Tester

Introduction

The hydrostatic head tester is designed to test the pressure that the material does not come into contact with the exuded water droplets side when the water pressure is continuously raised in a standard atmospheric environment, which is the hydrostatic pressure value of the material. It can quickly and accurately test out the encountered resistance when water penetrates through the material, to assess the material waterproof and moisture permeability.

Standards

AATCC 127 Option 2.

ISO 811.

ISO 1420.

GB/T4744.

FZT01004.

DIN53886.

JIS L1092.

EN20811

Applications

Hydrostatic Head Tester is designed to determine the waterproof property of outdoor wears, umbrella, and waterproof fabric. It is also used to test the resistance of permeability of synthetic blood for materials used in protective clothing. Dynamic, static, custom mode for different test requirements.

One side of the specimen is subjected to a hydrostatic pressure that increasing at a constant rate, then will be ended until three points of leakage appear on its other side. The instrument contains a high precision pressure control system, which could produce the test pressure in an internal water tank. Real-time pressure curve displays on the screen. Easy to use of build-in test mode for different standards.

Feature

1. The pressure using dynamic feedback regulation effectively prevent pressure overshoot.

2. Japan Panasonic servo motor and drive system, 16-bit A/D conversion.

3. Hydrostatic head tester -whole machine with aluminum alloy structure.

4. Sensor protection: automatic overload protection ( automatic switching of multi-sensor range).

Parameters

1. Measuring range: 500pa-200kpa(5-2000cmH2O)

2. Resolution: 1 pa

3. Accuracy: 0.2%FS

4. Pressure speed: 50--900mm/min (500pa-9kpa;5mbar-90mbar)stepless adjustable

5. Accuracy error: ≤1 mm

6. Specimen holder Pneumatic Grip Dimension: 100cm2

7. External dimension: 600×400×780mm(L×W×H)

8. Weight:50 kg

9. Power source: Ac 220V±10% 50HZ 100W or specified

在线联系供应商

Other supplier products

| Universal finger friction tester | Brief Introduction The main working principles of this device is through a test head, plus a certain amount of pressure, and carry a variety of ... | |

| Automatic cotton patting machine / Textile and Apparel - standard | Applications: All kinds of semi-finished down jackets sewing pieces and finished down jackets. Product Information: Clapping machine is simple, ... | |

| Scratch Resistance Tester | Product Introduction: The Scratch 5.5 Machine is a scratch and scratch test instrument for macroscopic scratches. It is a research-grade tribology... | |

| Xenon Arc Weather Ometer SI4000 | Introduction SI4000Xenon Arc Weather Ometer utilizes a xenon lamp to simulate ideal natural climate and sunlight conditions. It is suitable for te... | |

| Medical Suture Line Diameter Tester YY 1116 | The Medical Suture Thread Diameter Tester is a specialized testing equipment used for measuring the diameter or linear diameter of medical suture t... |

Same products

| Briefly describe the importance, core functionality and how to implement a hospital clock system solution | 卖方: California Triangle | In the healthcare industry, precise time synchronization is critical. Every second can be a matte... | |

| Sand and Dust Test Chamber for Automotive Connectors | 卖方: Standard International Group (HK) Limited | Operating Conditions: Ambient temperature: 5°C~+28°C (average temperature within 24 hour... | |

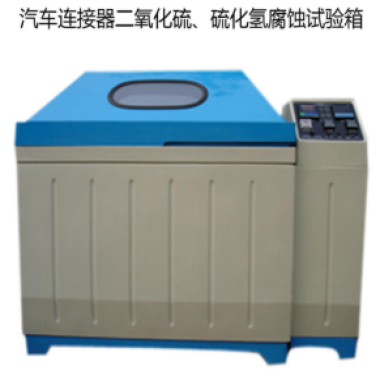

| Automotive Connector SO₂/H₂S Corrosion Test Chamber | 卖方: Standard International Group (HK) Limited | Standards: GB/T 10587-89. GB/T 2423.9-93: Chinese national standards for sulfur dioxide corrosio... | |

| Automotive Connectors Salt Spray Tester | 卖方: Standard International Group (HK) Limited | Applicable Standards: Neutral Salt Spray (NSS) Tests: GB/T2423.17. ISO 3768/3769/3770. ASTM B117... | |

| Air - tightness Testing Device for Automotive Connectors | 卖方: Standard International Group (HK) Limited | Main Functions: 1. Provide stable positive and negative pressures for testing the air - tightnes... |