Shanxi Rayforce Manufacture Co., Ltd.

Contact information

Our foundry was established in 2005, covers a total area of about 40,000 square meters and has over 300 employees. the foundry is equipped with several types of energy-saving & environmentally-friendly production lines including automatic or semi-automatic production lines of key processes: wax making, shell making, pouring, heat treatment. The machining factory is located in headquarters and is fully equipped with complete and advanced CNC machining equipment including 30 vertical and horizontal machining centers, and more than 30 CNC machines and 50 other machining equipments., the machining facility is fully independent from the casting foundry and has an independent management team and tailored business model to suit. In addition to the casting, forging and machining, it also has the facility to machine various profiles. Our company also has a lot of advanced inspection equipment, including Spectrometer, Metallographic Microscope, Tension Tester, Low Temperature Tester, X-ray Tester, MPT, UT, CMM, Video Measurement Machine and so on. With these advanced facilities & instruments, we are able to supply the high quality castings to our customers, and make products meeting comprehensive inspection requirements on chemical composition, mechanical properties, non-destructive testing and high precise dimensional inspections.

Products:

| Stainless Steel Investment Casting | The stainless steel has much better physical properties then iron and normal steel, but it possesses worse casting properties. Because the stainles... | |

| Metal Casting | Casting process usually refers to the metal casting process, is one of heating processing technologies handled by humans can be found recorded as e... | |

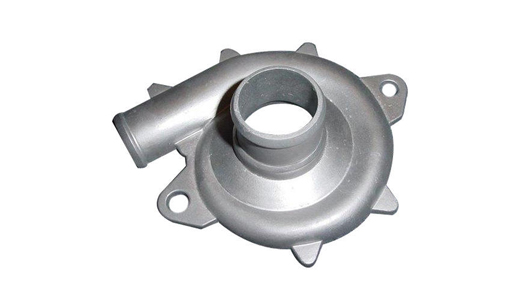

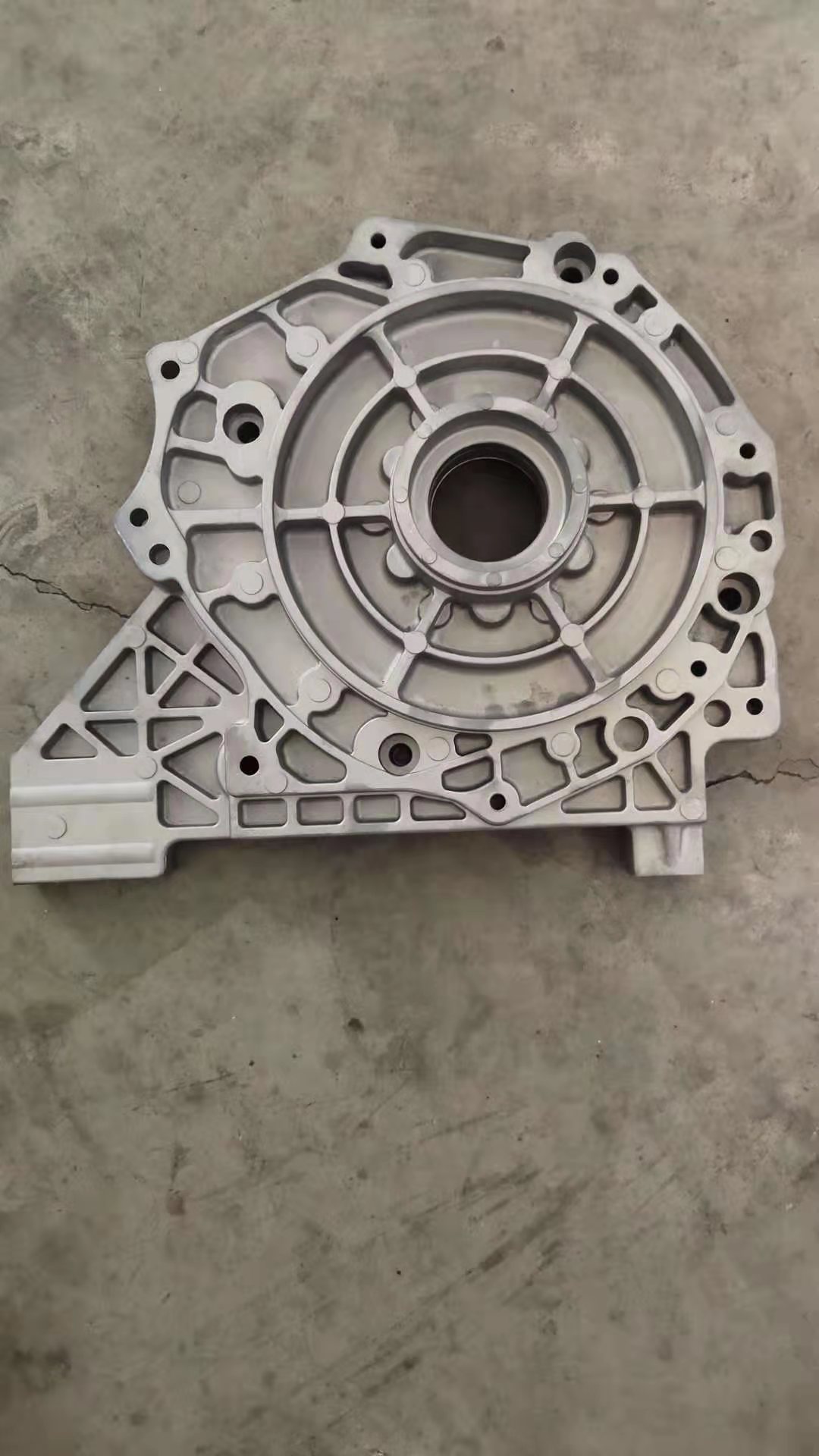

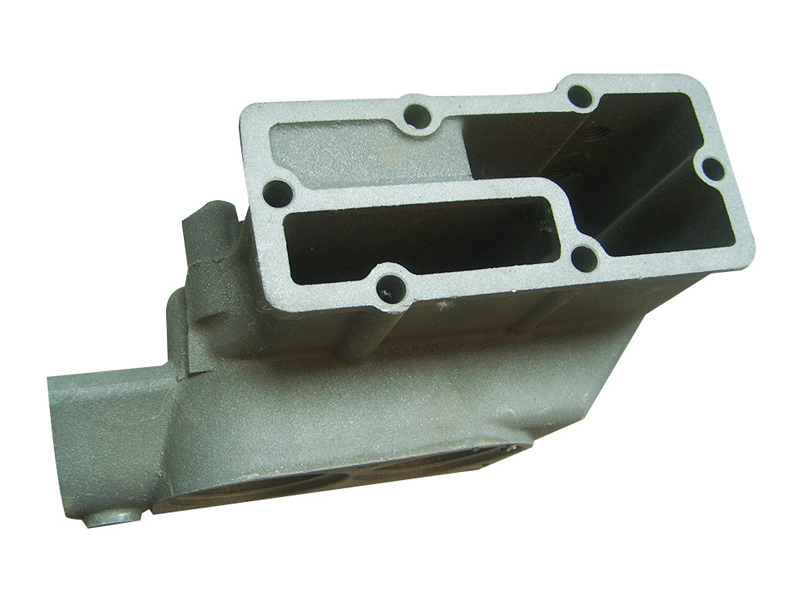

| Die casting | High precision die castinginvolves 3 key elements: the die casting machine, the mold, and the alloy materials, and the die casting could be describ... | |

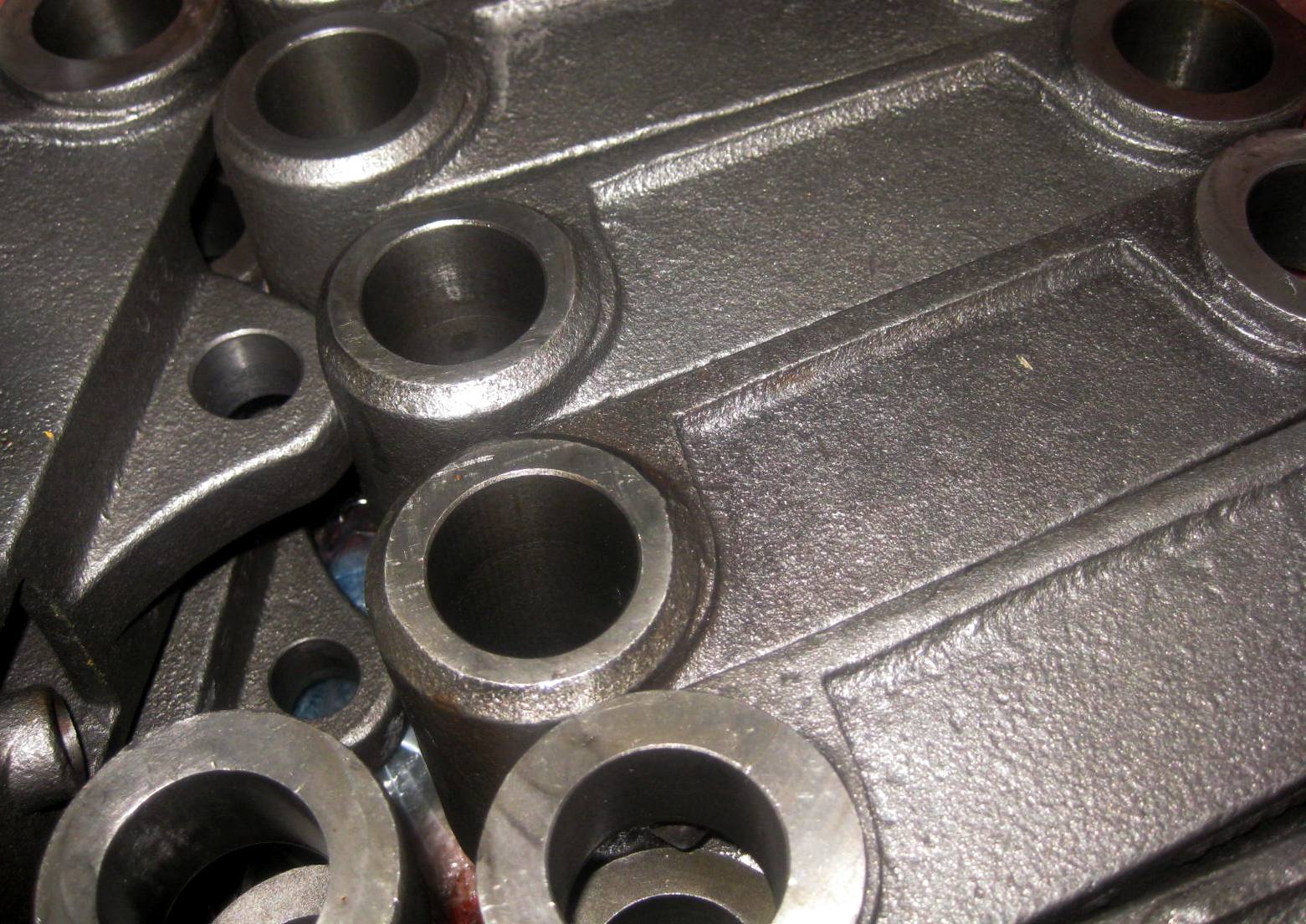

| Green Sand Casting | Sand casting means the main material consisting of the mold is sand, and the melted metal fills the casting cavity only by its gravity. Generally, ... | |

| Investment Casting | Direct investment casting, also called the lost-wax casting process, is actually an ancient metal investment casting technologywith a history of ov... | |

| Lost Wax Investment Casting | Lost Wax Investment Casting The lost wax casting aluminumprocess can differ depending on the application and the requirement, but it generally con... | |

| Low Pressure Die Casting | The low pressure casting machineis to let the melted metal flow into the casting mold under a certain degree of pressure, and solidify the casting ... | |

| Sand Casting | Sand casting chinais the most commonly applied method for casting the metal part. It suits most of the raw materials, ferroalloy, and non-ferroallo... | |

| Agriculture & Vehicle | Die Casting in Automotive Industry Rayforce's metal casting truckcan be applied to plough, tractor part, soil cultivation, planting, harvesting,... | |

| Aluminum Casting | Aluminum is a lightweight metal with silvery-white color. Because of its chemical features, aluminum never exists in the metallic form in nature. B... | |

| Application | Metal Casting Applications Marine Our metal casting chinacan be applied to anchor, stern frames, anchor winch part, container corner castings, pr... | |

| Art & Home Sculptures | Sculpture Moulding and Casting Rayforce's metal casting artcan be applied to Home accents, casting crafts, home sculpture, umbrella base, table ... | |

| Brass, Bronze, Copper Casting | As defined by its main properties, copper offers excellent electrical and heat conductivity, and good corrosion resistance ability as well. But nat... | |

| Compressors & Gears | Rayforce's metal die casting gearscan be applied to Turbo blowers, air control components, piston compressors, casting gears, etc. Application o... | |

| Ductile Iron Casting | Ductile ironis a type of graphite-rich casting iron, but it has not a long history that it was discovered in 1943. Ductile iron actually is not ... |