AC380V 50HZ SMT Wave Soldering Machine High Power For Full Production Line

CNSMT rich in WAVE SOLDERING develop MACHINE on SMT FULL LINE

Feature

| Control method: Press Kin+PLC (Kelita PCBASE wave soldering control software V1.0) |

| Transport Motor: 1P AC220V, 60W |

| Transport speed: 0~2000mm/min |

| Board size: 30 to 300mm(w) |

| Flux capacity: 6L |

| Pre-heating zone: 1300mm three-stage preheating, 600w*10PCS room temperature~250°C |

| Tin furnace heating: 1.2KW * 9PCS room temperature ~ 300 °C |

| Tin furnace capacity: 210KG (lead and tin materials are used) |

| Peak height: 0~12MM |

| Crest Motor: 3P AC220V, 0.18KW*2PCS |

| Washing claw pump: 1P AC220V 6W |

| Transport direction: Left → Right |

| Welding angle: 3 ~ 6 o |

| Flux Pressure: 3 to 5 BAR |

| Power Supply: AC380V 50HZ |

| Normal operating power / total power: 5KW/18KW |

| Dimensions: 3600(L)*1200(W)*1650(H) MM |

| Body size: 2700(L)*1200(W)*1650(H) MM |

| Net weight: 890KG |

Application

Failure analysis

Fold residue more

1. FLUX has a high solids content and does not contain too much volatiles.

2. The preheating is not performed before welding or the preheating temperature is too low (the time is too short for dip soldering).

3. Take the board too fast (FLUX failed to fully evaporate).

4. Tin furnace temperature is not enough.

5. There are too many impurities in the tin furnace or the tin is low.

6. Added anti-oxidant or anti-oxidation oil.

7. Apply too much flux.

8. There are too many scorpions or open components on the PCB and there is no warm up.

9. The component legs and plate holes are out of proportion (the holes are too large) to increase the flux.

10. The PCB itself has pre-coated rosin.

11. In the tin-bismuth process, FLUX is too wettable.

12. PCB process problems, too few vias, causing FLUX volatility.

13. Hand solder immersed in the wrong angle of the PCB.

14. During the use of FLUX, no diluent was added for a long time.

Send product request

Other supplier products

| SMT Yamaha Pick And Place Feeder KHJ-MC100-00 YS12 Metal Material | Khj-mc252-00 GEAR,IDLE P2 feed-in pinion SS12MM feed-in accessories KHJ - MC251-00 GEAR, IDLE P1 Khj-mc136-01 GEAR,IDLE F3 SSY8MM electric f... | |

| AC380V 50HZ SMT Wave Soldering Machine High Power For Full Production Line | CNSMT rich in WAVE SOLDERING develop MACHINE on SMT FULL LINE Feature Control method: Press Kin+PLC (Kelita PCBASE wave soldering control soft... | |

| SMT Stick Feeder KXFW1KSRA00 For Panasonic CM602 Pcb Assembly Equipment | SMT Stick Feeder KXFW1KSRA00 Original New Use in Panasonic CM602 Pcb Assembly Equipment 8*2MM P / E M9A5NWM0000 double reel8*4MM P / E M9A1NWM0000 ... | |

| Ys12 / Ys24 Intelligent SMT Feeder For Yamaha KHJ-MC200-00 SM20 YSM40 | KHJ-MC101-01 BODY,FEEDER 11-1 KHJ-MC101-02 BODY,FEEDER 1 (2008/4/25) NG1-2 KHJ-MC101-03 BODY,FEEDER 1 (2008/6/25) NG2 KHJ-MC110-00 MOTOR,FEED 13 KH... | |

| Hitachi HTGD Screen Printing Squeegee Blades For Solder Paste Printer | Hitachi HTGD printer squeegee SMT Stencil Printer Squeegee 150-600MM IN STORK Quick Detail SMT HCSqueegees/SMD SqueegeesSMT HCSolder paste prin... |

Same products

| Hc-501s Low Noise Energy Saving Rotary Air Blower | Seller: Greentech International (Zhangqiu) Co., Ltd | HC rotary air blower structure and working principleThe rotary blower has an exquisite structure ... | |

| Common Rail Injector Nozzle 880P119092 Common Rail Injector Nozzle A6510702887 | Seller: China lutong | Common Rail Injector Nozzle 880P119092 Common Rail Injector Nozzle A6510702887Chris Whats/ app:+... | |

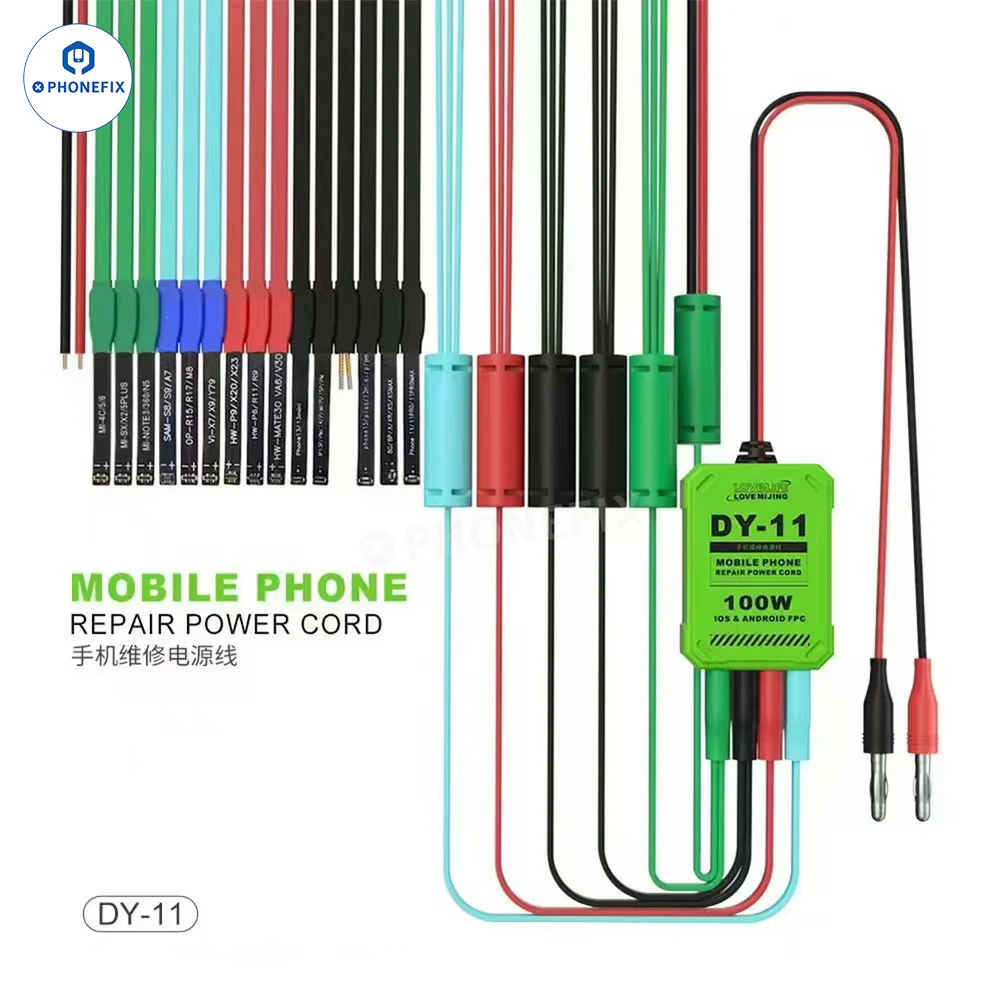

| MIJING DY-11 Power Cable for iPhone and Android Phone Boot Testing | Seller: Phonefix | The MiJing DY-11 mobile phone repair power cable uses iOS and Android FPC interfaces, specificall... | |

| AI845 Analog Input Module 3BSE023675R1 | Seller: Hangzhou Perfect Technology Co., Ltd. | General Information Product ID: 3BSE023675R1 Medium Description: AI845 Analog Input Module, 8 c... | |

| T9401 T9402 Digital Input Module | Seller: Hangzhou Perfect Technology Co., Ltd. | The 9401 (8 channel) and 9402 (16 channel) are 24Vdc digital input modules. They accept galvanica... |