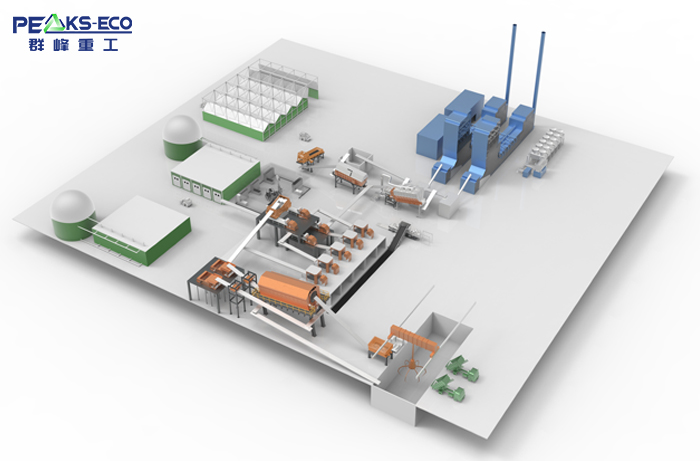

Vertical Waste transfer Station System

Vertical Waste transfer Station System

The system has adopted the most advanced vertical compression technology. The theory of the process, in simple words, is discharging waste from above to a vertical container below taking advantage of the gravity. It is as simple as we dump the garbage in the trash can every day. Our technology is to make full use of the limited space and simplify the process of waste transfer.

Thewaste container is considered as the core of the whole system. Every equipment of the transfer station is working around the container directly or indirectly. After the transfer truck places the container in the discharging position, the discharging hopper will be put above the container so that the waste can be discharged directly to it permitting no waste dropping out of the container. When the container is fairly full, the compactor will move to above the container and start to compress. As long as the container is completely full, it will be mounted on a transfer truck though a special guiding device to be transported for final disposal. The whole process is fairly simple and operation-maintenance friendly. It can work properly even when the power is off. Besides, central control panel, weighing device, deodorization anddust-cleaning devices are considered in the system.

Main features

Transfer truck and garbage truck can be working in the same site without rampway.

Direct vertical discharging to the container with higher efficiency.

Vertical compression from above to below inside the container allowing no waste dropping out of the box.

The device is fully sealed allowing no waste liquid leakage from the container.

Heavy detachable transfer truck is recommendable. More than 16 tons per truck.

Taking advantage of the gravity, the waste will be discharged directly to the container and compressed by the compactor, which only needs 30kw for maximum power.

Overground:

Thewhole set of equipments is located on foundationbuilt on the ground. The design includes the rampway and the area of operation site, which can be fully closed or semi closed (only the rampway will be located outside).

The nominal capacity of the design is 1000 tons/day and the station will occupyapproximately an area of 8000 ㎡. The operation is 78m long, 67m wide and 18.7m high, approximately 4900 ㎡ for the main buildings.

The main workshop of the station contains discharging area, transfer area, rampway, compaction and load area, auxiliaryarea. The compaction and load area is located in the center of the studio, the second floorof which is the area of discharging and the first floor is the auxiliaryarea.

Underground:

The whole operation area is located underground. Over the station small buildings and green area can be built. Consequently this type of waste compaction system is ideal to be built under park, square and urban green zone as a perfect solution for insufficient space problem in cities.

Vertical Waste transfer StationSystemhas a large capacity of production, which can reach to 1200 tons/day. Themain buildings of the system occupy an area of 3940 ㎡ and the operation area is 60m long, 56m wide and 10 high.

The waste collection trucks and transfer trucks enter and leave the station using rampway. The discharging area is located in the first underground floor, the transfer area, office area and other area in the secondunderground floor.

Send product request

Other supplier products

| waste to energy system,waste treatment system,waste sorting plant | waste to energy system,waste treatment system,waste sorting plant Waste to Energy(WTE) technology involves the thermal treatment of waste to releas... | |

| waste balers | waste balers The is designed to meet the needs of the user, which vary depending on the size and type of material they wish to compact and tra... | |

| Vertical Waste Transfer Station Project | Vertical Waste Transfer Station Project Dezhou Qunfeng Machinery Manufacturing Group, located in the east of Ningjin economic development area of ... | |

| FDY-1250 Full Automatic Baler Machine,baler machine for paper,paper baler machine | FDY-1250 Full Automatic Baler Machine,baler machine for paper,paper baler machine Usage Specialized in recycling and compressing the loose material... | |

| Commercial Waste Sorting Technoloy | Commercial Waste Sorting Technoloy is cutting-edge technology in the solid waste management industry. It is an automated sorting and recycling... |

Same products

| UV Accelerated Weathering Tester丨UV Accelerated Weathering Chamber | Seller: Standard International Group (HK) Limited | Standard ASTM D4329、ASTM D4587、ASTM D4799 、ASTM D5208、ASTM G151、ASTM G154 、EN 927-6、EN 1297 、EN ... | |

| UV Condensation Aging Test Chamber丨UV Condensation Aging Tester | Seller: Standard International Group (HK) Limited | Standard ASTM G154.ISO 4892-3.JIS K 7350. andSAE J2020for UV exposure testing. IEC 60068-2-78fo... | |

| UV Aging Test Chamber丨UV Aging Test Mechine | Seller: Standard International Group (HK) Limited | The UV aging test chamber is suitable for all kinds of geo-synthetics, such as light resistance, ... | |

| UV Light Degradation Chamber丨UV Light Degradation Tester | Seller: Standard International Group (HK) Limited | Features and Benefits 1.TheUVlamps can be selected in different wavelength ranges, including U... | |

| Weatherometer Laboratory Testing Equipment(UV) | Seller: Standard International Group (HK) Limited | Features and Benefits 1. UVA-340. UVB-313 and other UV lamps, a single power of 40 watts, can ... |