What is the Difference Between Overmolding and Insert Molding?

What Is the Difference between Insert Molding and Overmolding

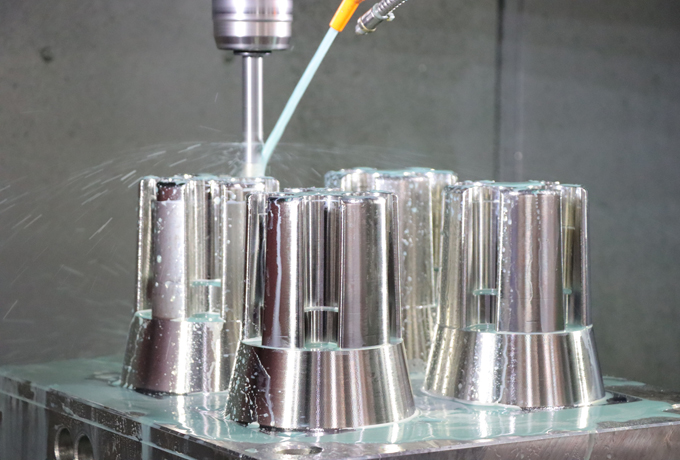

Plastic injection molding is one of the most widely used processes for manufacturing high-quality and extremely precise parts. The process is known for its multiple advantages. Consequently, a wide range of industries have adopted this part manufacturing method. There are many types of injection molding technologies currently in use, depending on the parts to be produced. Among the many types, overmolding and insert molding are the two most common injection molding technologies.

As the name implies, overmolding is a process of molding one material on another. The first component is made in an injection mold and then placed in the second mold, where overmolding material is added. This technology combines a variety of plastics to achieve practical or aesthetic purposes. For example, people may use plastics of different hardness to mold soft plastics over hard plastics to make the parts easier to grasp. The use of multiple colors of plastic in overmolding parts can also distinguish the products from those of other brands. Overmolding is often used on the handles of tools such as screwdrivers, electric drills, or toothbrushes.

The advantages of overmolding injection molding are:

(1) Improve material flexibility

(2) Long service life

(3) Enhance security

Insert molding is a subset of custom injection mouldingtechnology, similar to overmolding. Before the actual injection molding, the metal part is put into the mold cavity, and the insert is accurately positioned in the mold by manual operation or mechanical arm. Then the mold is closed and the plastic is molded on the insert to form a part. Most of the finished parts produced by this method are a combination of thermoplastics and metal parts, which are often used in aerospace, automotive and medical fields.

The advantages of insert injection molding are:

(1) Reduce assembly and labor costs

(2) Reduce the weight of parts

(3) Shorten assembly time

The above is the insert molding vs overmolding differenceBoth have their own advantages and applications. The corresponding technology can be selected according to the type of parts to be manufactured.

If you want to know more details of insert molding vs overmolding, please visit our website.

As one of mould manufacturers in china, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

| Injection Molding Surface Finish | Injection MoldSurface Finish Do not use the finest whetstone, sandpaper, or abrasive polishing paste at the beginning of mold polishing, as you ... | |

| Injection Mold Design Engineering | Injection mold design engineeringis a procedure at the first stage of injection molding process, which develops the injection mold designs to impro... | |

| Injection Molding Materials | What materials are used in injection moulding?Materials used in injection moulding generally include abs molding, nylon injection molding, polycarb... | |

| Plastic Injection Mould Tooling | Plastic molds are tools that are matched with plastic mold making machines in the plastic processing industry to give plastic products a complete c... | |

| Injection Molding Materials | Common Injection Molding Materials What materials are used in injection moulding? Materials used in injection moulding generally include abs mold... |

Same products

| What is the Difference Between Overmolding and Insert Molding? | Seller: Taizhou Huangyan Fow Mould CO., LTD | What Is the Difference between Insert Molding and Overmolding Plastic injection molding is one... | |

| BOPP Film (Biaxial-Oriented Polypropylene Film) | Seller: Asia Pacific International Co., Limited | BOPP Film (Biaxial-Oriented Polypropylene Film) BOPP film (Polypropylene Film, BOPP foil, BOPP ... |