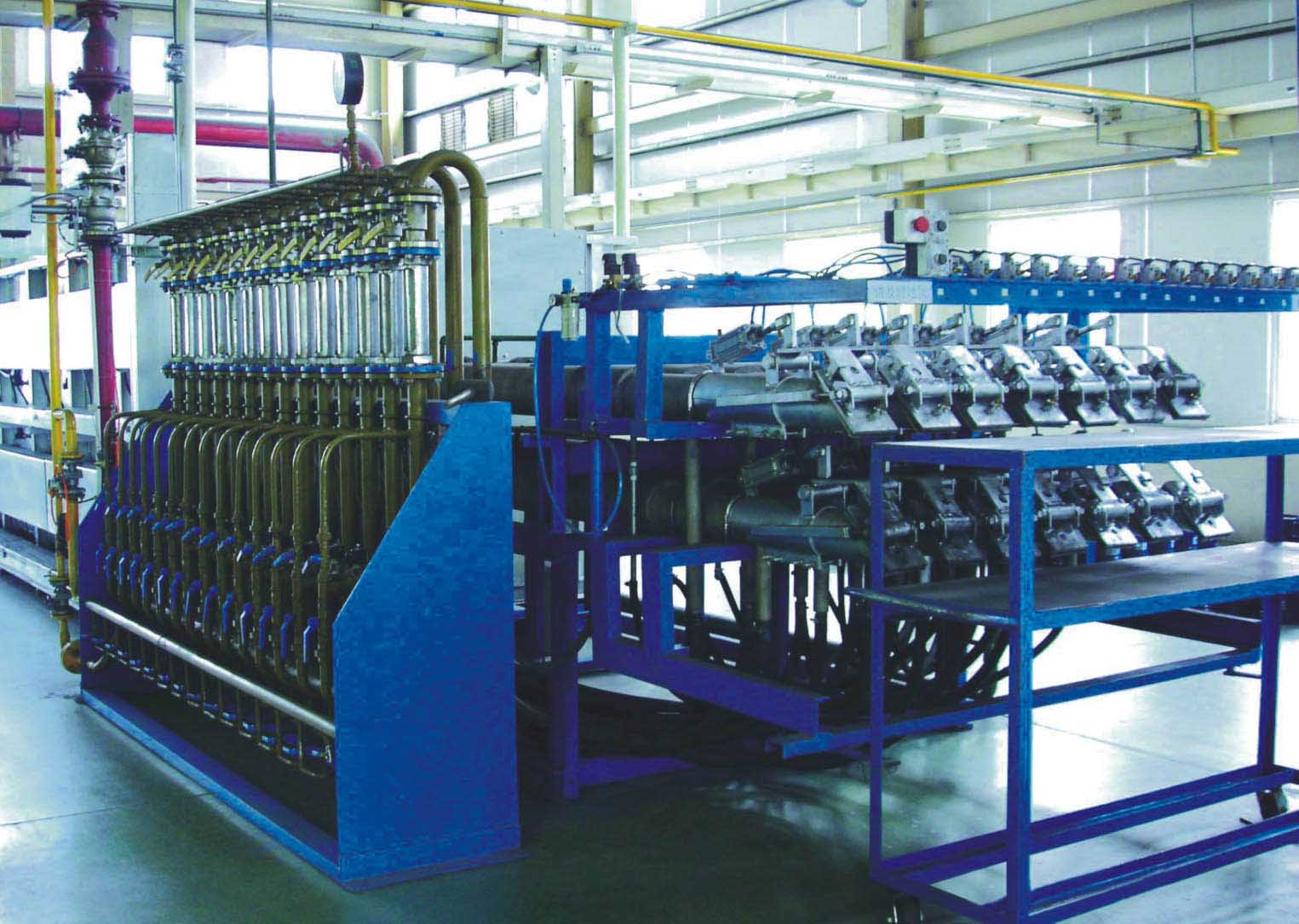

HIP and Gas Quench Furnace

Application

It is used for HIP and rapid cooling gas quench treatment of various metal, copper base, iron base powder, friction resistant material ceramic material and etc.

Technical Features

1. Horizontal twin chamber, horizontal loading structure. Furnace door type can be customized design.

2. Gas quenching chamber is bottom to top or left to right gas circulation, which has high heat exchange rate..

3. The HIP chamber is closed before gas quench, to save energy.

4. According to the treating jobs, users can choose to configure axial-flow type high power gas quenching fan or centrifugal high power gas quenching fan.

Other supplier products

|

|

Reduction Furnace Manufacture |

DescriptionSteel belt furnace is mainly applied for reduction of Fe powder, Cu powder, Co powder, Ni powder, W powder, Mo powder, etc. It can also ... |

|

|

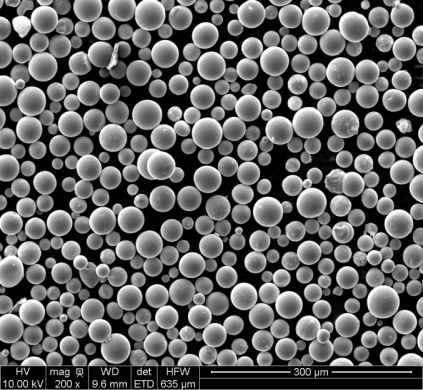

Spherical Titanium Alloy Powder |

ACME is a high-tech enterprise specialized in manufacture of industry heating equipment for new material and energy. Based on technology innovation... |

|

|

China Calcination Furnace Supplier |

DescriptionRotary furnace is mainly used for metal salt calcination and metal oxide reduction process, such as APT calcination, blue tungsten reduc... |

|

|

18-Tube Automatic Reduction Furnace |

DescriptionMulti-tube furnace is mainly used for metal powder (like tungsten, moly, etc) reduction.Technical Features1. Multiple tube heating guara... |

|

|

Vertical Vacuum Water Quenching Furnace |

Vertical vacuum water quenching furnace is applied for the solution of titanium alloy in aerospace industry, such as TC4, TC16, beryllium bronze in... |

All supplier products

Same products