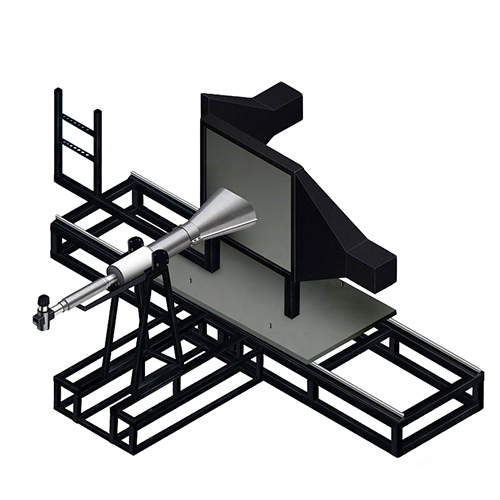

ACME Steel Belt Furnace

Description

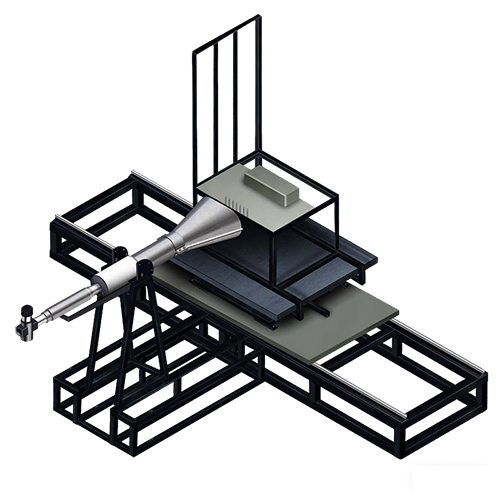

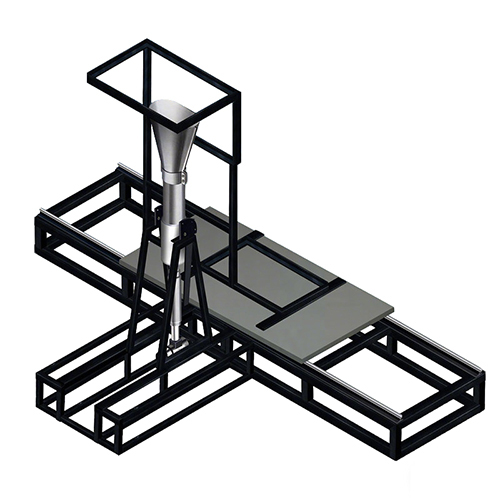

Steel belt furnace is mainly applied for reduction of Fe powder, Cu powder, Co powder, Ni powder, W powder, Mo powder, etc. It can also used for calcination of metal salt like cobalt formate and APT.

Technical Features

1. Continuous production features low energy consumption and large production capacity.

2. The furnace without boat and dead corner ensures good temperature uniformity, complete reduction and high quality.

3. Steel belt reduction furnaces are configured with full automatic loading and unloading operation, which makes stable product quality and low labor force.

4. The furnace is equipped with gas recycle system, which can improve the gas efficiency and lower the gas consumption.

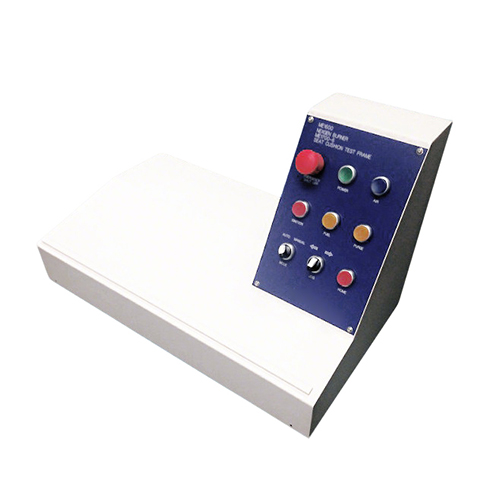

5. It has functions of remote control operation, remote malfunction diagnosis and remote program update functions.

Send product request

Other supplier products

| Vertical Bottom Loading Vacuum Annealing Furnace | DescriptionVertical bottom loading annealing furnace is satiable for bright annealing of materials like tool steel, die steel, high-speed steel, ul... | |

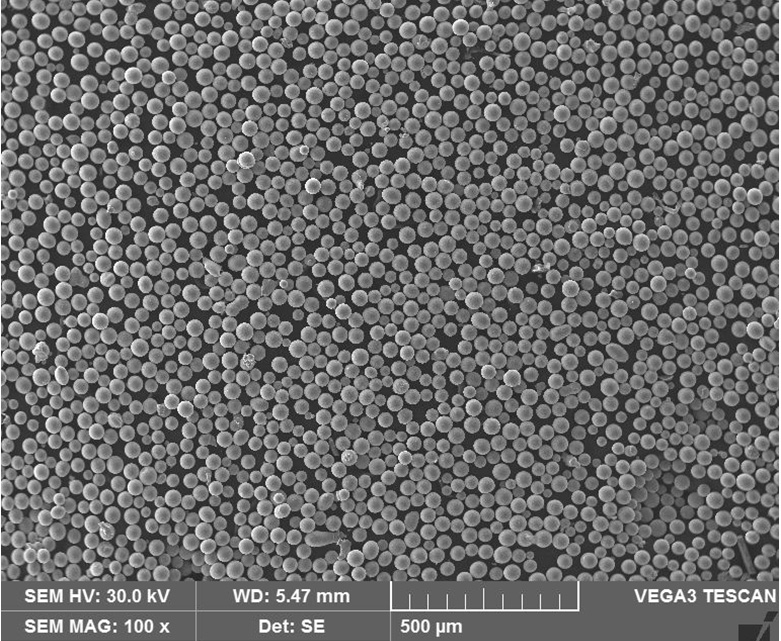

| Spherical Moulding Alloy Powder | ACME is a high-tech enterprise specialized in manufacture of industry heating equipment for new material and energy. Based on technology innovation... | |

| Mesh Belt Sinter Furnace | DescriptionMesh belt sinter furnace is mainly used for high temperature sinter of powder metallurgy ferrous and copper parts, such as oil bearing, ... | |

| Horizontal Twin Chamber Vacuum High Pressure Gas Quenching Furnace | DescriptionHorizontal gas quenching furnace is used for gas quenching of materials like tool steel, die steel, high speed steel, super high strengt... | |

| Vacuum Debinding and Sinter Furnace | Vacuum debinding and sinter furnace is mainly suitable for debinding and sinter process of tungsten alloy, heavy alloy, moly alloy, titanium alloy ... |