Tungsten Powder Reduction

Description

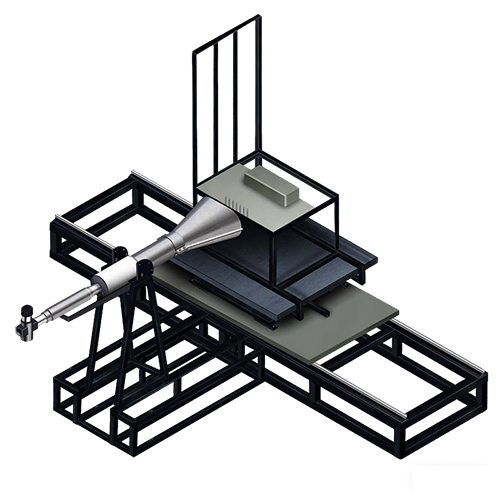

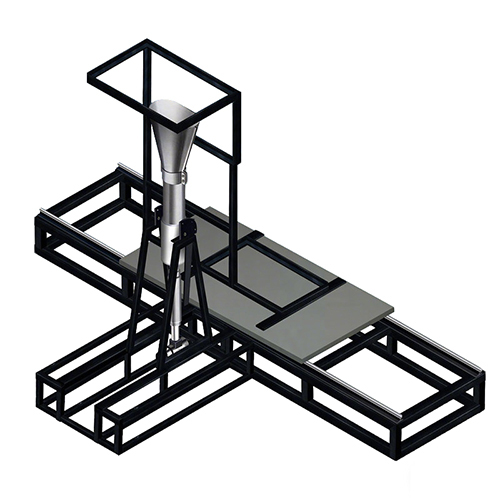

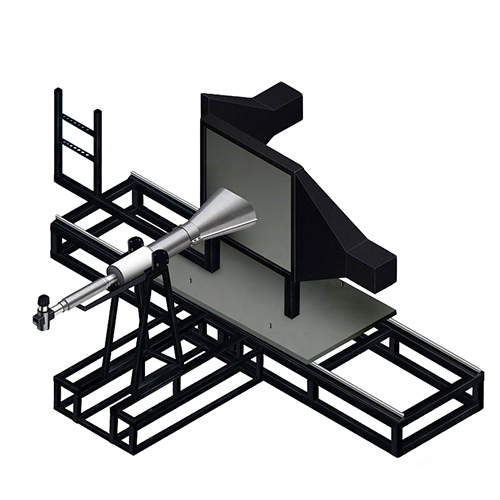

Pusher type furnace is mainly suitable for metal powder (like tungsten, moly, etc) reduction and powder metallurgy part sintering.

Technical Features

1. Multiple tube heating assures good temperature uniformity and large production capacity.

2. The intermittent loading and unloading type assures good sealing performance and low gas consumption.

3. Pusher furnaces are configured with full automatic boat charging, boat pushing, unloading and boat dumping service, which ensures stable quality and low labor force.

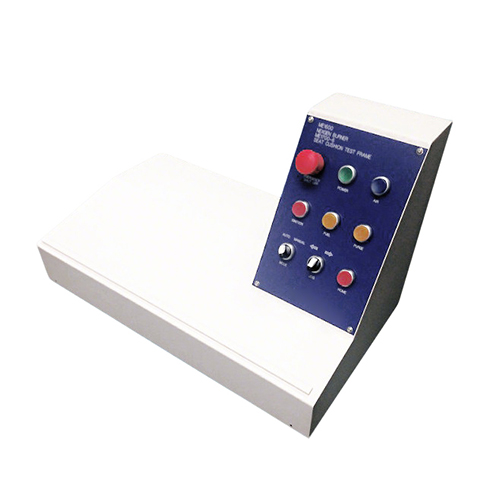

4. Furnace has the functions of remote control operation, remote malfunction diagnosis and remote program update functions.

Send product request

Other supplier products

| Automatic Carburizing Furnace | DescriptionAutomatic carburizing furnace is mainly used for carburizing of tungsten powder, reduction of metal powders, sintering of tungsten coppe... | |

| Continuous Graphite Purification Furnace | Continuous graphite purification furnace is used for continuous high temperature graphitizing purification of graphite powder, which can also compl... | |

| Vacuum Debinding and Sinter Furnace | Vacuum debinding and sinter furnace is mainly suitable for debinding and sinter process of tungsten alloy, heavy alloy, moly alloy, titanium alloy ... | |

| Horizontal Vacuum Carbonization Furnace | Horizontal vacuum carbonization furnace is applied for high temperature carbonization treatment of C/C, carbon fiber insulation material and high t... | |

| ACME Rotary Furnace | DescriptionRotary furnace is mainly used for metal salt calcination and metal oxide reduction process, such as APT calcination, blue tungsten reduc... |