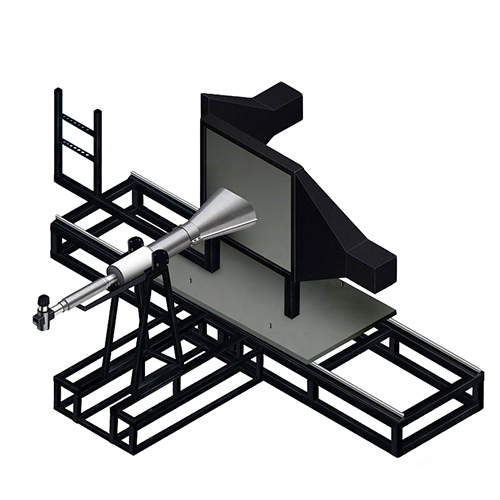

ACME Rotary Furnace

Description

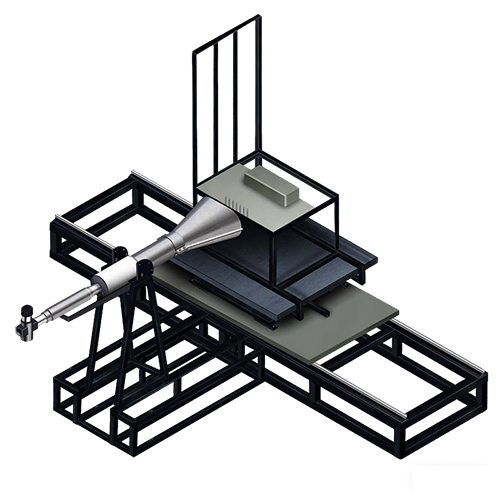

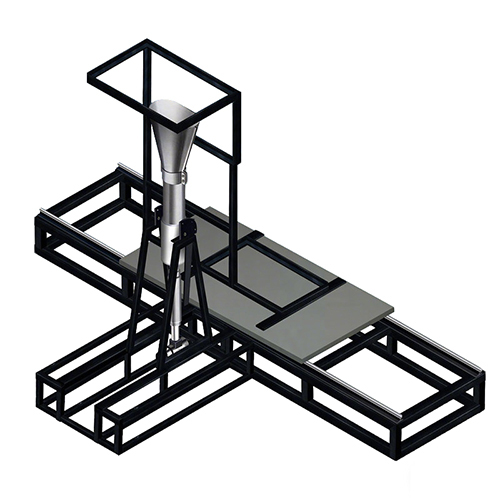

Rotary furnace is mainly used for metal salt calcination and metal oxide reduction process, such as APT calcination, blue tungsten reduction, etc.

Technical Features

1. The rotary reduction furnaces use rotary tube which will result in good powder fluidity.

2. The intermittent loading and unloading type assures good sealing performance and low gas consumption with gas recycling.

3. Full automatic loading and unloading is available, which assures stable product quality and low labor force.

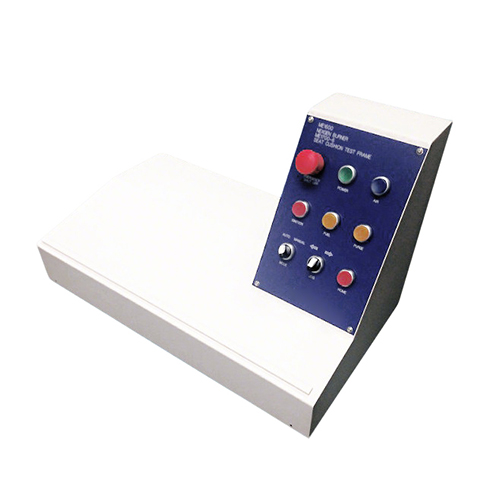

4. Furnace has the functions of remote control operation, remote malfunction diagnosis and remote program update functions.

Send product request

Other supplier products

| Horizontal Vacuum Graphitization Furnace | Horizontal vacuum graphitization furnace is applied for high temperature graphitization and purify treatment of C/C, graphite, carbon fiber insulat... | |

| HIP and Gas Quench Furnace | ApplicationIt is used for HIP and rapid cooling gas quench treatment of various metal, copper base, iron base powder, friction resistant material c... | |

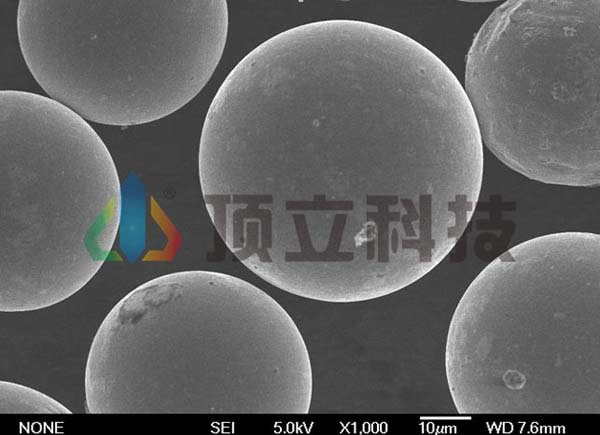

| Spherical Aluminum Alloy Powder | Based on technology innovation and professional service, ACME provides high-end industrial heating equipment for customers in various fields, such ... | |

| CVD coating Furnace(SiC) | Horizontal CVD tube furnace (Silicon Carbide) uses methyltrichlorosilane (MTS) as air source to make material surface oxidation resistant coating a... | |

| Spherical Stainless Steel Alloy Powder | Based on technology innovation and professional service, ACME provides high-end industrial heating equipment for customers in various fields, such ... |