Textile Grease Extraction Apparatus

Rapid Grease Extraction Apparatus

Testing Standards ofRapid Grease Extraction Apparatus:

Edana method ERT 155

Applications:

Rapid Grease Extraction Apparatus is designed to determine the grease or finish content of wool or synthetic samples by solvent percolation and evaporation. Suitable for fiber, yarn or fabric. Available with 1, 2 or 3 extraction units.

Product Information:

The Rapid Grease Extraction Apparatus was developed specifically for obtaining the oil content of tops and similar materials sufficiently quickly for the results to be available at the time of processing.

The principle of extraction is percolation of a solvent through the wool sample in a simple metal tube. The extract, as it drips from the tube, is collected by a light aluminium tray held between two metal rings mounted on a temperature-controlled hot-plate.

Features:

1.The instrument consists of pedestal, extraction tub, weight, plunger, cotton wool plug, tray, and the hot-plate.

2.The tube should be positioned in the hole in the lower support member of the apparatus, and the plunger boss placed in the hole in the upper support member.

3.In use the plunger is placed through the boss and down into the tube. The weight is then located on top of the plunger.

Testing Method:

Before starting a series of tests, the hot-plate is allowed to warm up to a suitable temperature (set by the power regulator knob). The correct temperature has been obtained when the solvent evaporates from the dish almost as quickly as fresh solution filters through to replace it. This prevents flooding of the tray and losing oil to the brass ring.

The temperature must not be too high, however, or the solvent will evaporate violently as the drops of solution hit the hot tray.

Before each test a pre-weighed aluminium tray is placed on the hot-plate brass ring. The tray location ring is then placed on the tray to secure it and to maintain a good thermal contact with the lower ring. The bottom of the tray must not touch the hot-plate.

This test method is most suitable for extracting loose wool or combed slivers, but it may also be used for yarn. It is not suitable for fabric unless it is first disintegrated into yarn to facilitate uniform packing in the extraction tube.

Technical Parameters ofRapid Oil Extraction Apparatus:

1.Range of temperature: ambient temperature-250℃;

2.Loading mode: aggravate weights;

3.Timing range: 1-9999min;

4.Accuracy of temperature control: ±1℃;

5.Number of specimens: 3;

6.Extracting solvent: Petroleum ether, ether and dichloromethane;

7.Outside dimension: 170×170×380mm(L×W×H);

8.Weight: 4.4kg(9.7lb);

9.Power supply: AC220V, 720W;

10.Power dissipation >: 175W.

Send product request

Other supplier products

| UV Carbon Arc weather Meter | Introduction:Weatherproof test: This test is conducted to find out the impacts on some items and parts in a natural condition bysuch factors as sun... | |

| EN 143 Mask Automatic Filtering Performance Tester | The tester is used for performance testing of filter elements, disposable masks, filter media, etc. for respiratory protection products. It's suita... | |

| Pilliscope Assessment Viewer | :起球评估查看器 (PAV) 适用于所有起球和勾丝测试的评估标准。评估结果是通过在指定光源下将样品与标准卡进行比较而得出的。它是马丁代尔起球测试、ICI 球测试、ICI 勾丝测试、随机翻滚起球测试、圆轨迹法起球测试等的辅助评估工具。它广泛应用于纺织和服装行业,符合大多数起球测试标准。技术参... | |

| Taber abrasion resistance test machine | Range of applicationTABER abrasion resistance tester and wear resistance tester can be replaced by wheel and weight,which apply to the abrasion res... | |

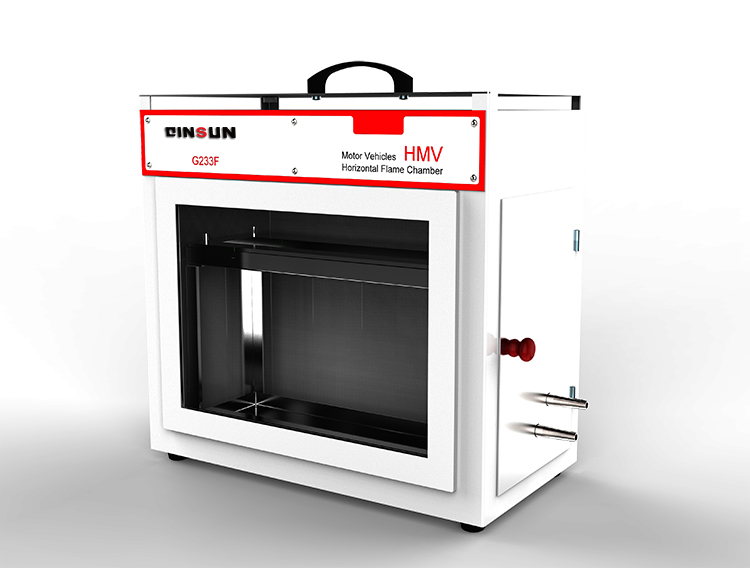

| Horizontal flammability tester | Horizontal Flammability Tester Standards: ISO 3795, FMVSS 302, DIN 75200, SAE J369, ASTM D5132, JIS D1201, AU 169 Applications: The Horizontal Fl... |

Same products

| Blanket Flammability Test Machine | Seller: Standard Groups | Bed Blanket Flammability Tester-It is mainly used for testing the flame retardant performance of ... | |

| High Temperature Oxygen Index Tester | Seller: Standard Groups | The High-Temperature Oxygen Index (TOI) measuring instrument determines oxygen index at up to 125... | |

| Limiting Oxygen Index Tester | Seller: Standard Groups | The Limiting Oxygen Index Tester measures the minimum oxygen concentration needed to sustain comb... | |

| Vertical Flammability Tester | Seller: Standard Groups | Vertical Flammability Chamber for measuring the vertical flame spread for children’ sleepwe... | |

| 45 Degree Flammability Tester | Seller: Standard Groups | Application 45 Degree Flammability Tester is used to determine the burning characteristics of te... |