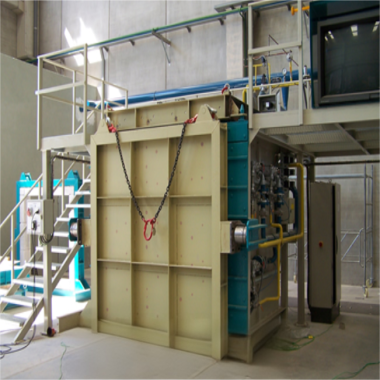

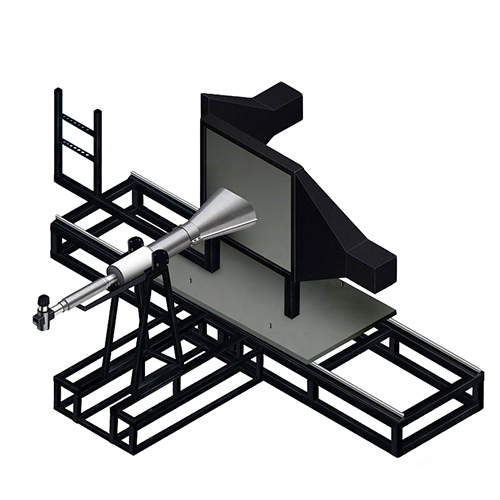

Vertical Fire Testing Furnace

Fire resistance performance of material provide important information for evaluation samples and Assembly properties. This furnace is a quantitative method of material vertical position and ability to withstand high temperatures.This furnaces can be used for evaluation of fire resistant products, such as walls, doors, air dampers, connections and infiltration sealing agent. Evaluation samples a number of features, including load-carrying capacity, fire control, heat transfer, and so on.

The fire resistance test furnace is designed to comply with the relevant parts of building materials in fire resistance test of EN1363-1.1363-2 hydrocarbon curve and relevant requirements of ISO standard 834.and is similar to other States of the relevant provisions. The equipment was specifically designed and after years of improvement, formed a kind of test specimens configuring reliable and accurate methods and necessary part of the combustion chamber, which can be placed on the combustion chamber contains samples of various types of restrictive framework. The control at a specific time, temperature and pressure conditions, the response to heating of the sample to evaluate specific performance standards.

The furnace in the production and installation of lining and tested in the factory, According to your preset function, disassemble into parts packed into trailers suitable for heavy transport.

Standards:

EN1363-1

ISO 834

Features:

•The inner space of this fire resistance test furnace is 3000mm (w) x 3000mm (h) x 1300mm (d), Lined with 1400 class insulation bricks, refractory filling block and the slag plate.furnace top laying with special-shaped brick and lined with refractory material in situ.

• In some regions apply diatomaceous earth insulation and the super thermal insulation material at low temperature, in a hazardous area area and base of the combustion chamber all for to cement the connection as much as possible using the 42% dense alumina refractory brick lining in the 6-hour high temperature during the test will provide sufficient insulation.

• Fixation of available customized vertical test samples for testing

• Refractory insulation brick used in heat-resistant lining, refractory filling block and the slag plate

• Top shop special-shaped brick and lined with refractory material

• Furnace using low carbon steel, reinforced with c channel steel and h-beams, steel resolve hot deformation

• Sample fixed boxes mounted on the furnace front, fixed by four sets of doors

• Cold noodles with inorganic fiber pad, heat-resistant insulated bricks along the wall pad, shop in situ high temperature block

• Four observation port is located on the long side of the wall, use a heat-resistant quartz glass, clever, convenient operators watch the whole sample in a test case

• Air cooler insulating frame lightweight aluminum fiberboard sliding doors without using a observation port, slide the door blocking the oven available in the heat

• Twelve specialized luminous flame burner. Each fuel burners are fitted with flame supervision devices to ensure combustion combustion safety

• Use button switches at any time automatically inserted into the mouth, according to thepresetheat curve light burning mouth, such as the BS 476-DI20-24bu, EN 1363 and IMO the hydrocarbon curve. Manual control can be lit to specify burning mouth burning mouth.

• The three genuine leaks smoke cross section is circular, each of which contains an airlock. These three air brakes is a round of high-level stainless steel structure and its shaft water cooling. Flue liner here for biodegradable ceramic fiber material.

• Furnace using low carbon steel, reinforced with c channel steel and h-beams, solve the thermal deformation of the steel issue, designed as a strong deformation structures. Strengthening plates for burners, hole, thermocouples, pressure and monitoring points provide holes. Steel frame is designed to ensure that you have considered the use function. The durable nature of the equipment to ensure its life expectancy in a test environment.

Send product request

Other supplier products

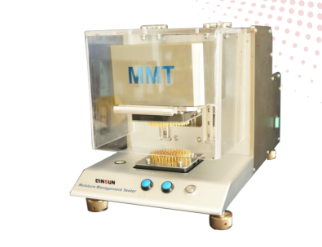

| MMT Liquid Water Separation Tester - lab instrument | We are a professional testing instrument manufacturer offering complete laboratory testing solutions.please contact us for details and technical su... | |

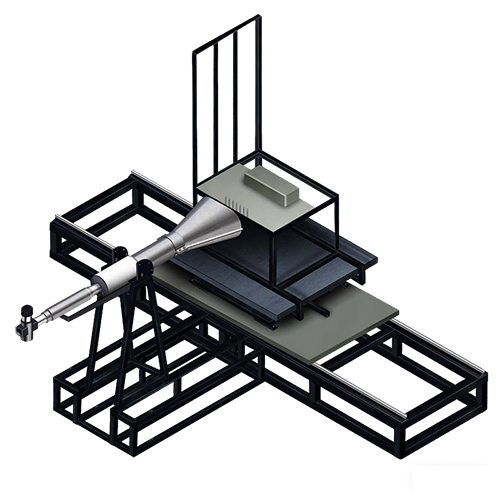

| Roller Abrasion Tester | Car tire performance and its service life is directly related to the running condition of the car, and has a great impact on the safety driving of ... | |

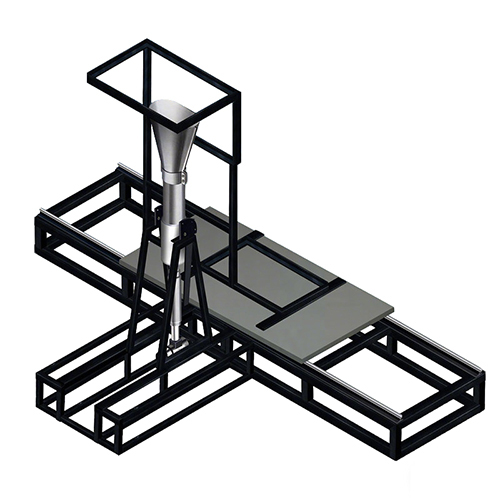

| Diaper Anti-Side Leakage Performance Tester | The Diaper Anti-Side Leakage Performance Tester is designed to accurately measure the liquid loss of nonwoven materials and evaluate the anti-side ... | |

| Fully automatic spinneret mirror inspection instrument (short fiber spinneret)| Testing Equipment | The Fully Automatic Spinneret Mirror Inspection Instrument (Detector) is designed for automatic inspection of chemical fiber filament spinnerets, s... | |

| AATCC KMS-M6 Washer, KMS-M6D Dryer | The AATCC KMS-M6 Washer and KMS-M6D Dryer are precision textile testing instruments designed to simulate industrial laundering and drying processes... |