Oil Filter Performance Tester

Many materials and components in various industries are subjected to repeated cycles of operation, stress, or exposure. Evaluating their performance and durability requires testing methods that go beyond single-event or static measurements. "Multiple Passes Through Tester" refers to systems designed to replicate these repetitive actions in a controlled laboratory environment.

The fundamental principle involves setting up a test where the item under evaluation undergoes a specific interaction or process, and this process is then repeated for a large number of cycles or "passes." The test aims to accelerate the effects of long-term use, allowing manufacturers and researchers to assess degradation, wear, fatigue, or the ability to maintain performance over time.

Examples of testers that utilize the "multiple passes through" principle include:

Hydraulic Filter Multi-pass Testers: Hydraulic fluid containing contaminant is repeatedly circulated through a filter element to measure its particle removal efficiency and dirt holding capacity over time.

Zipper Fatigue Testers: The zipper slider is repeatedly opened and closed along the zipper chain to assess its durability and functional life.

Hook and Loop Fastener Fatigue Testers: Hook and loop tapes are repeatedly engaged and disengaged to evaluate the degradation of closure strength.

Shoe Bending Testers: Complete shoes or shoe components are repeatedly flexed to assess their resistance to bending fatigue.

Flow Fatigue Testers (e.g., for filters): Components are subjected to repeated cycles of pressure or flow to evaluate structural fatigue.

In these testers, the number of cycles or passes is carefully controlled and monitored. Performance parameters are measured at intervals or at the end of the test, and failure criteria are typically defined based on changes in performance, appearance, or structural integrity.

Meet the standard

ISO 16889

ASTM D5170

ASTM D2060

ASTM F3445

ISO 3724

ISO/DIS 19438-2004

ISO 4548-12:2000

GB/T 18853-2015

GB/T 8243.12-2007

Send product request

Other supplier products

| Textile formaldehyde content tester | In China, the national mandatory standard "national textile products basic safety technical specifications" GB18401-2003. with effect from 1 Januar... | |

| Spray Rating Tester | Applications Spray Rating Tester is used to determine the surface wetting resistance of fabrics. Standards ISO 4920:2012: Textiles—Determi... | |

| Children's Product Comprehensive Force Tester - lab instrument | Applicable Standards GB/T 31701 - 2015. GB/T 6675 - 2003. GB/T 32599. EN71 - 1. BS 7909. ASTM F963. 16CFR1500.51. GB/T 22704. etc. Application Sc... | |

| Photovoltaic Acid Mist Test Chamber | The Photovoltaic Acid Mist Test Chamber is a specialized device designed to simulate coastal environments with high salt fog concentrations, enabli... | |

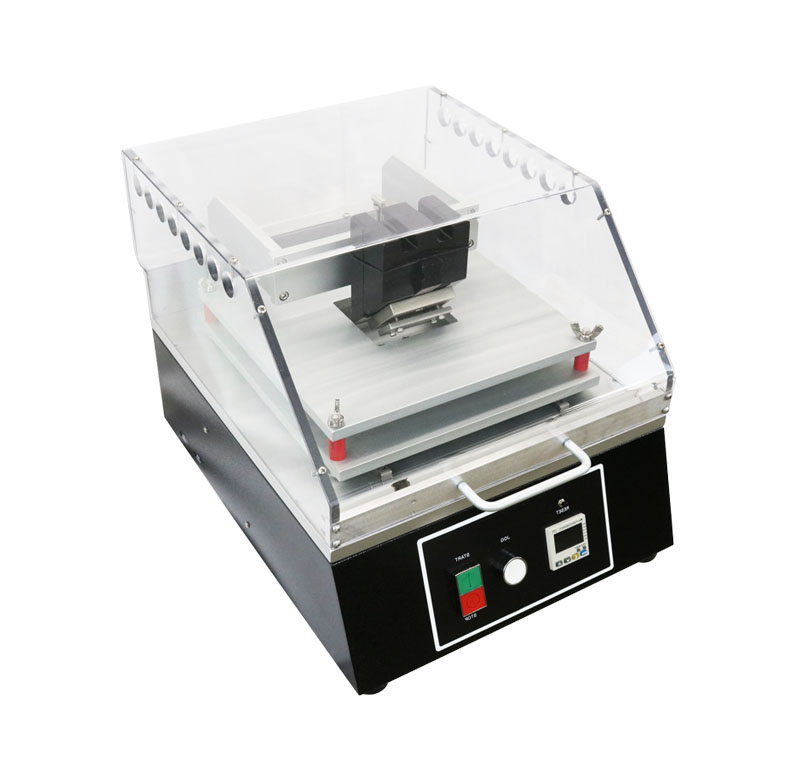

| Taber Type Abrasion Tester | TheAlcohol abrasion resistance testercomplies withUL817 and other relevant standards "special rubber fixed to the machine friction rub hammer surfa... |

Same products

| Air Intake Filter Test System | Seller: Standard Groups | The Air Intake Filter Test System is designed for testing industrial air filters and engine air f... | |

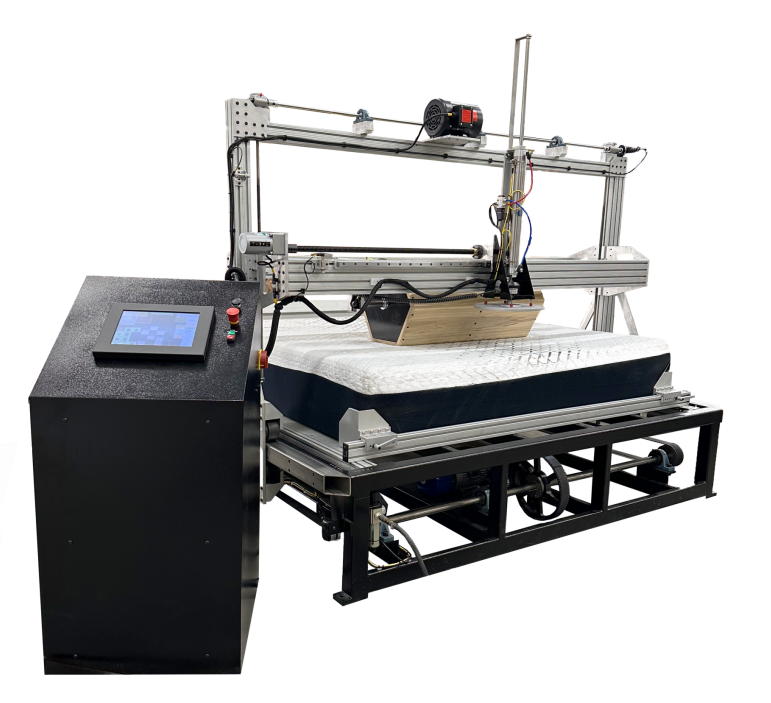

| Mattress Spring Fatigue Tester,ASTM D3574 ,how to test mattress for sagging | Seller: Standard International Group (HK) Limited | The King Size Foam Fatigue Tester is a single-station pneumatic fatigue testing system designed f... | |

| Mattress Rollator,ASTM F1566 ,Mattress Durability Tester,Mattress Fatigue Tester | Seller: Standard International Group (HK) Limited | The Mattress Rollator is a laboratory durability testing system designed to evaluate the long-ter... | |

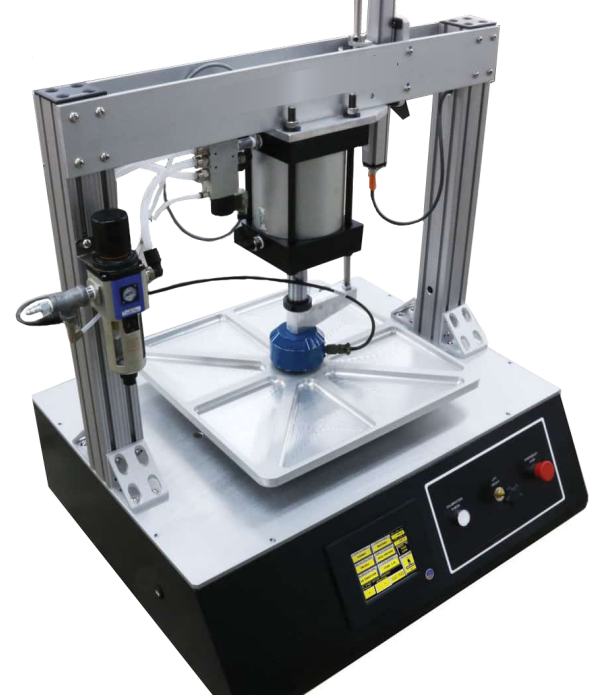

| HD2 Pneumatic Foam Fatigue Tester,ISO 3385,Foam Fatigue Testing Machine | Seller: Standard International Group (HK) Limited | The HD2 Pneumatic Foam Fatigue Tester is a heavy-duty, single-station laboratory testing machine ... | |

| VW Heel Abrasion Tester,ISO 4649 ,Heel Performance Testing Machine | Seller: Standard International Group (HK) Limited | The VW Heel Abrasion Tester is designed to evaluate the wear resistance of floor covering materia... |