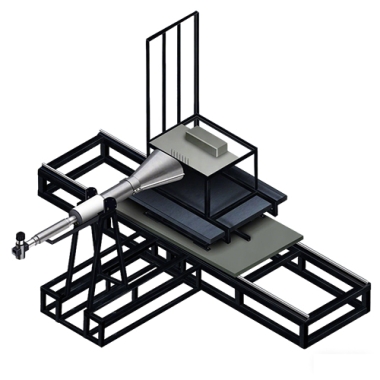

Bundle wire and cable burning test machine

The bundled wire and cable combustion testing machine is manufactured in strict accordance with GB/T 18380.31-2022. equivalent to IEC 60332-3-10:2009 standards. It is used to evaluate the ability of vertically installed bundled wires, cables, or optical cables to inhibit vertical flame propagation under specified conditions. This testing equipment is independently developed and manufactured by Shanghai Qianshi Precision Electromechanical Technology Co., Ltd., offering high cost-effectiveness and comprehensive after-sales service.

Application

Apply to evaluate suppression ability of spread of fire for bundles installed wires and cables ,under specified conditions.

Standards

IEC60332-3-10:2000:Tests on electric and optical fibre cables under fire conditions - Part 3-10: Test for vertical flame spread of vertically-mounted bunched wires or cables

GA306.1-2007:Flame retardant and fire resistive cables - Classification and requirement for flame retardant and fire resistive cables with plastic insulation - Part 1: Flame retardant cables

Main components

Testing chamber, electric control system, air source, ignition source flew control system (propane gas and air compressed gas), steel elevator, Fire extinguishing devices, emissions purification equipment (user option).

Features

1. Equipped with a standard stainless steel ladder, conforming to the requirements of GB/T18380.31;

2. Two sample support racks are included;

3. The ladder is made of stainless steel, which is corrosion-resistant and easy to clean;

4. An air inlet port measuring 800±20(W) × 400±10(D) is located in the lower part of the chamber, 150±10mm from the front of the chamber;

5. A K-type armored thermocouple with a 2mm diameter is installed inside the chamber;

6. The airflow inside the combustion chamber can be stably controlled at (5000±500) L/min.

Parameters

| Feature/Specification | Details |

|---|---|

| Overall Space Size | 2500mm (length) * 3200mm (width) * 4500mm (height) |

| Material | Thermal insulation with a heat transfer coefficient of 0.7W∙m⁻²∙K⁻¹, i.e., coated 65mm thick mineral fiber stainless steel plate |

| Air Source | Control gas flow through the box at (5000 ± 500) L/min, stabilize air flow rate during test; spraying device to forcibly stop burning after test completion |

| Steel Ladder Type | Standard steel ladder width: 500mm; Wide steel ladder width: 800mm |

| Discharge Purification Device | Test box equipped with a collection and washing smoke device that does not alter air flow through the test box |

| Ignition Source | One or two belt-type propane gas burners with supporting flow meters and venturi mixers; fire supply surface drilled with 242 flat metal plates with 1.32mm diameter apertures, center distance of 3.2mm, staggered in three rows of 81. 80. and 81 holes respectively, within a nominal size of 257×4.5mm; additional guide holes on each side of spout plate to maintain steady flame burning |

| a) Flow Control | Each burner equipped with a rotameter for accurate control of propane and air inflow rate |

| b) Airflow Rate (Test Conditions: 100kPa, 20℃) | Air: (77.7 ± 4.8) L/min; Propane: (13.5 ± 0.5) L/min |

| Ignition Source Position | Torch placed horizontally, (75 ± 5) mm away from front surface of cable sample, (600 ± 5) mm away from bottom of test box, symmetrical with axis of steel ladder; ignition point located in center between two rungs of steel ladder, at least 500mm away from lower end of sample |

| Observation Window | Tempered glass observation window surrounded by stainless steel edge |

| Exhaust System | Spiral exhaust fan; 2 sealing push and pull plates; 2.0mm stainless steel |

| Air Inlet | 1 (Φ160mm) |

| Bottom Fixed Frame | 40mm * 40mm square tube production |

Send product request

Other supplier products

| Aircraft Seat Cushion Fuel Burn Test System | The Aircraft Seat Cushion Fuel Burn Test System is a dedicated aviation fire testing platform designed to evaluate the fuel fire performance, flame... | |

| Single Cable Vertical Flame Tester | Single Cable Vertical Flame Tester is used for the vertical flame propagation of a single insulated wire or cable is a bench scale test to determin... | |

| Bubble Pressure Method Membrane Pore Size Analyzer - lab instrument | We are a professional testing instrument manufacturer offering complete laboratory testing solutions. If you need more information or wish to explo... | |

| Steam Shrinkage Test Machine - lab instrument | I. Product Overview TheVapor Shrinkage Testeris a specialized thermal analysis instrument designed to measure dimensional changes in textiles, pol... | |

| Fabric ici pilling and snagging box | Standard GB/T 4802.3: China’s national standard for textile pilling resistance. BS EN ISO 12945-1: European standard for wool-based textile... |

Same products

| Air Intake Filter Test System | Seller: Standard Groups | The Air Intake Filter Test System is designed for testing industrial air filters and engine air f... | |

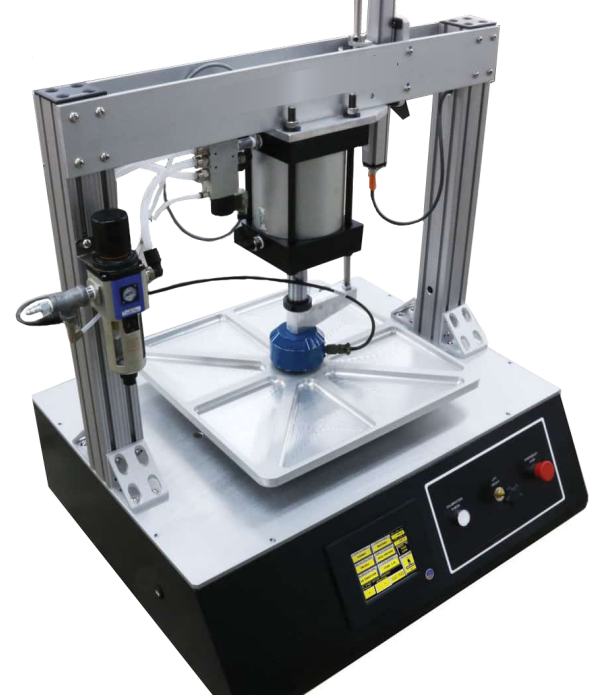

| Mattress Spring Fatigue Tester,ASTM D3574 ,how to test mattress for sagging | Seller: Standard International Group (HK) Limited | The King Size Foam Fatigue Tester is a single-station pneumatic fatigue testing system designed f... | |

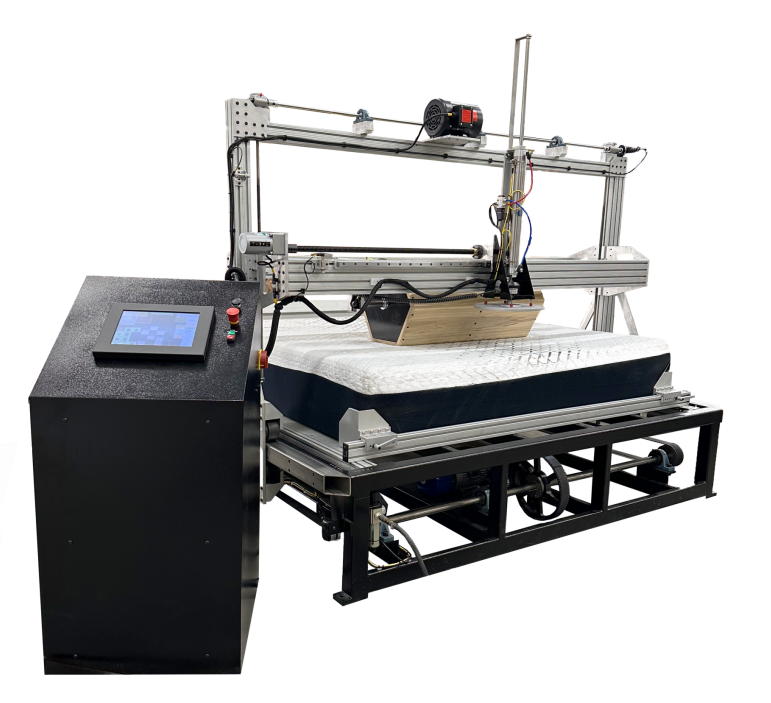

| Mattress Rollator,ASTM F1566 ,Mattress Durability Tester,Mattress Fatigue Tester | Seller: Standard International Group (HK) Limited | The Mattress Rollator is a laboratory durability testing system designed to evaluate the long-ter... | |

| HD2 Pneumatic Foam Fatigue Tester,ISO 3385,Foam Fatigue Testing Machine | Seller: Standard International Group (HK) Limited | The HD2 Pneumatic Foam Fatigue Tester is a heavy-duty, single-station laboratory testing machine ... | |

| VW Heel Abrasion Tester,ISO 4649 ,Heel Performance Testing Machine | Seller: Standard International Group (HK) Limited | The VW Heel Abrasion Tester is designed to evaluate the wear resistance of floor covering materia... |