KHGK Auto welding machine,TIG welding machine for pipe

KHGKSeriesoforbitpipe-tube

automaticpulseargonarcweldingmachine

Orbitalweldingmachine

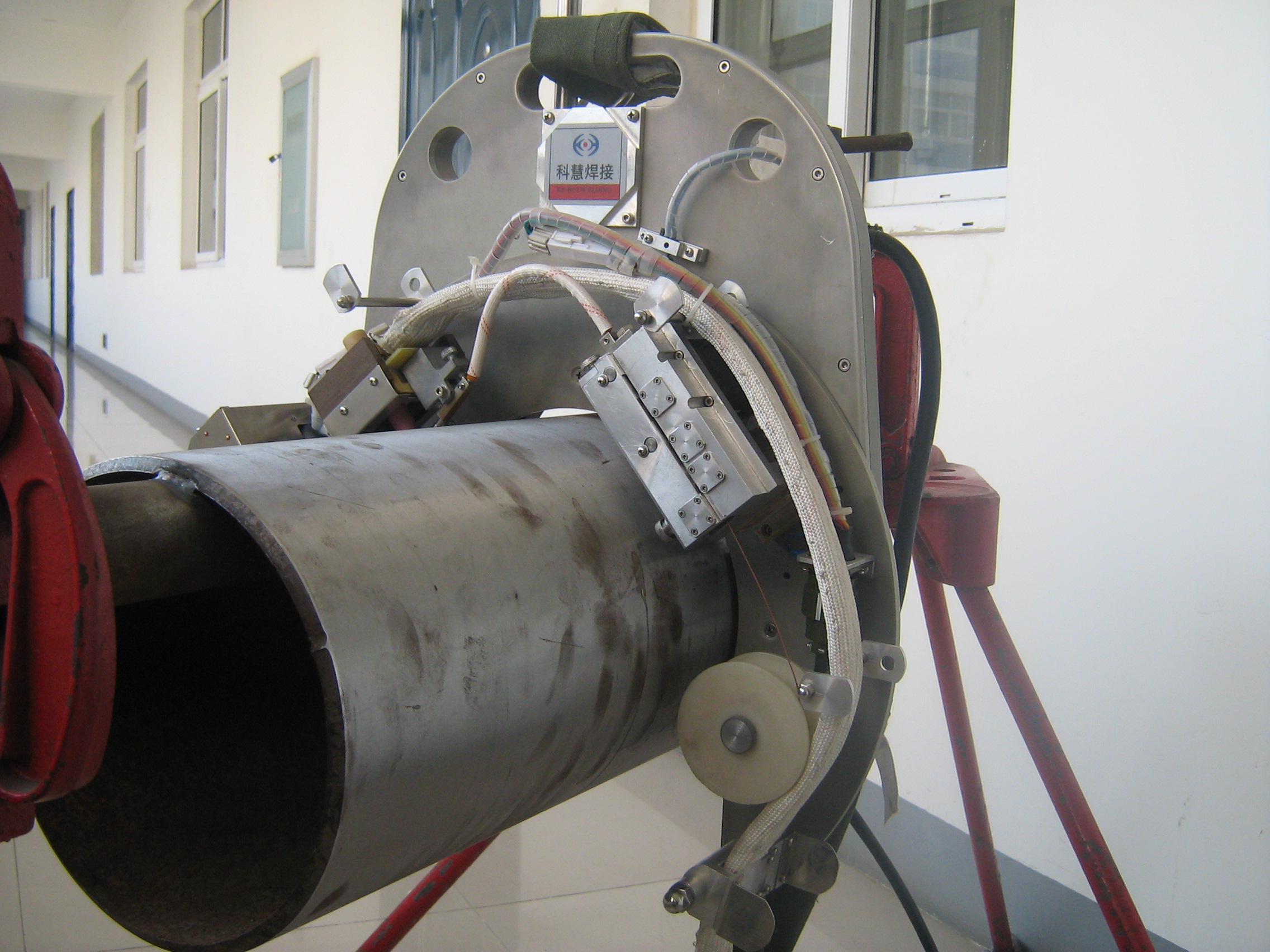

KHGKseriesisdesignedforallpositionautomaticweldingoftube-tube,tube-bend,tube-flange,andtube-valvebodywhosetubeoutsidediameterisbetweenφ16~φ300mm,andweldingmaterialscontaincarbonsteel,alloysteel,stainlesssteel,etc.KHGKseriescanbeusedforfillingwireornotfillingwirebuttwelding.

lKHGKseriesconsistsofpower,controlsystem,coolingsystem,remotecontrolandweldinghead,etc.Separateddesignfortheequipment,makesitnotonlyconvenienttooperationandmanagement,butalsofacilitateforproductionworkshoporproductionsitetomovefreelyandeasily.

Performance

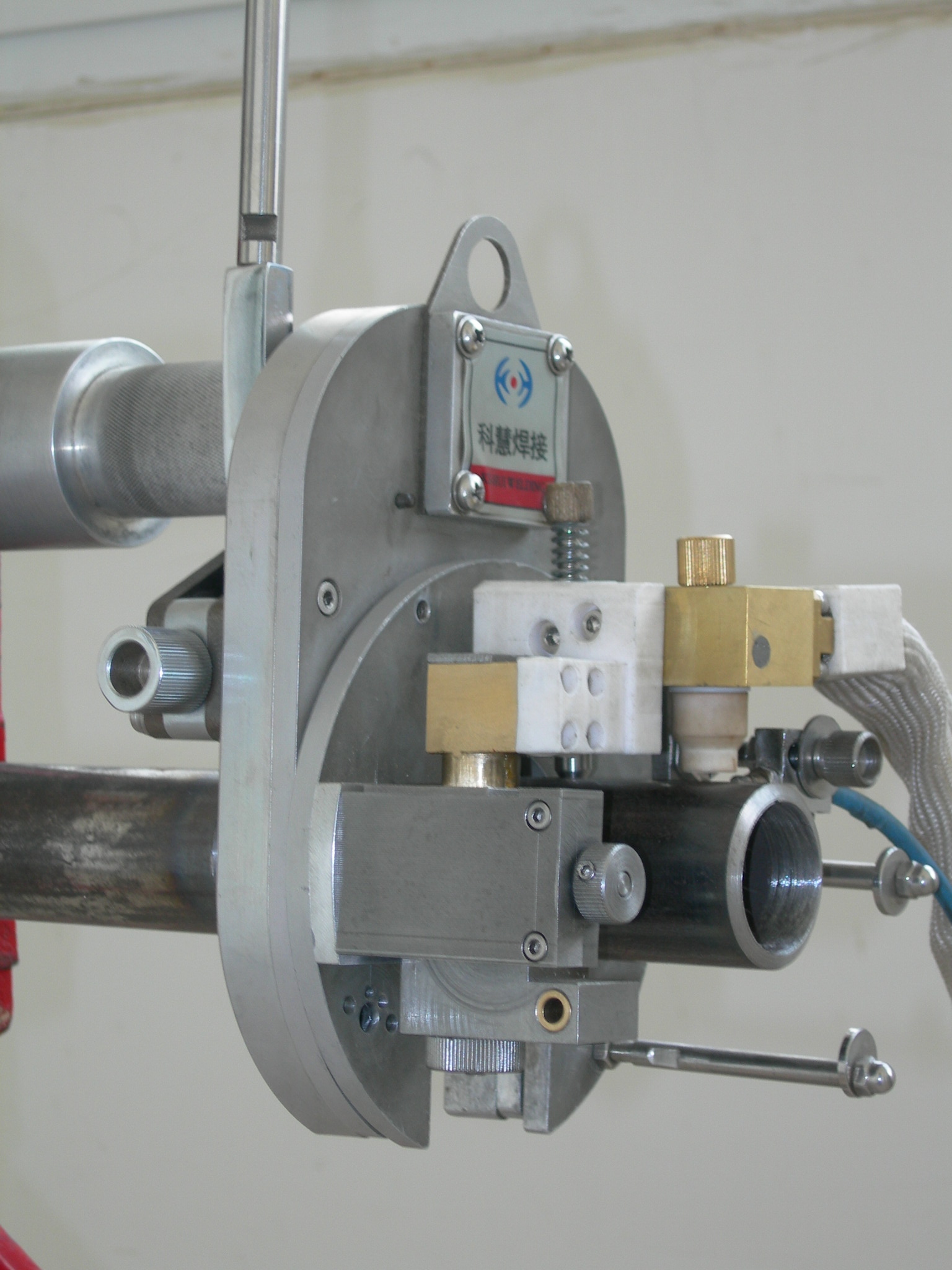

lWeldingheadhavefivespecifications,accordingtodimensionalconditionandproductrangecanchooseoneorseveralspecificationsofthenose

lSuitableforvariouskindsofpipe-pipejointandvariousgrooveform

lWireunitaccordingtoworkingenvironmentdifferent,canadoptbuilt-inwireorexternalwire;

lWeldingheadmaincomponentsareusedaviationmaterials,lightweight,structuralstability,andhightemperaturenodeformation

lDriveandwirefeedadoptssteppingmotor,makenoseoperatereliable.

lNoseequippedwithbalancer,operationconvenience,reductionoflaborintensity

lAdoptPLCcontrolsystemandLCDtouchhuman-machineinterface,canbestoredupto100groupsofweldingstandard,eachgroupofweldingscopecandivide1~12section,inputissimple,andnotneedprofessionalbasisandspeciallanguage

PLCcontrolsystem

LCDtouchhuman-machineinterface

UsedPanasonicIGBTinvertercontroldcpulsepower,guaranteehighweldingefficiencyandstrongarcstability,Weldbeadmoldingbeautiful;

lWeldingtorchusingforcedwatercooling,cankeeplong-termwork;

lNose(exceptofKHGK16-40A)canchoosethearclengthautomatic

adjustmentandyawingdevice.Accordingtodifferentrequirementsyawingcanbeusedmechanicalswingandmagneticpendulum;

lMandatorywatercoolingsystem,equippedwith16litersstainlesssteeltank,notaffectedbyfieldwaterhydraulicconditionslimits,coolingfully,reliableconvenient;

lCarstypeintegrationdesign,mobilefreedom,equippedwithsmalltoolboxandargongasbottleseat,andalsocanreceiveheadtothecar,ensureequipmentsecuritystoragewhenitnoused.

Remotecontroller

Figure10showstheremotecontroller.

l4-4-1Definitionoftheswitch

lNumber1:‘Electricarctrack’

SwitchAutomaticallyadjustthelengthofelectricarc,iftheswitchisturnedon.

lNumber2:‘Peakpointcurrent+’and‘PeakpointCurrent–'

SwitchPressonetime,thepeakpointcurrentmayincreasesordecreasesby5ampere.

lNumber3:‘Swing’Switch

Itisusedtoturnonthefunctionofweldingswing,ifturnonit,theweldingheadwillfillweldingwirewithgroovebyswingdeviceduringthewelding.

lNumber4:‘Wirefeeder’Switch

Ifturnontheswitch,thewirefeederstartstowork,inthecaseoffusionweldingprocess,pleaseturnoffit.

lNumber5:‘upanddown’buttonfor‘Trochangleadjustment’

Itisusedtoupordownthetroch,andadjusttheangelbetweentungstenandpipesurface.

lNumber6:‘leftandfight’buttonfor‘Trochangleadjustment’

Itisusedtomovethetrochtoleftorright,andadjusttheangelbetweentungstenandpipesurfaceandensurethetopofthetungstenagainsttothepositioninthemiddleofthegroove.

lNumber7:‘Welding/test’Switch

Whenset‘welding/test’switchonto‘test’,then,pressthe"start"button,themachinestarttodetecttheweldingprocesses.

Whenshifttheswitchonto‘welding’,then,pressthe"start"button,themachinemaybegintoweld.

lNumber8:‘Wirespeed+’and‘Wirefeedspeed–’

Itisusedtoadjustthewirefeederspeed.

Note:Byusingthisbutton,itonlychangesthecurrentfeedingspeed,anditwillnotchangetheweldingspeedwhichhasbeeninputintoprogram.Ifyouneedtochangethewirefeedingspeedinthewholeweldingprocess,itneedstoresetitinthe“Parametersetting’interfaceaftertheweldingcompleted.

lNumber9:“Speed’switchforswingdevice

Itisappliedtoadjustthespeedoftheswingdevice.

lNumber10:‘Amplitude’Switchfor‘swingadjustment’

Itisusedtoadjusttheamplitudeofswing.

lNumber11:‘wireadjustment’Switch

Itisusedtoinsertweldingwiretoweldingheadorpullouttheweldingwirefromweldinghead.

lNumber12‘Rotate’Switch

‘Rotate’switchisusedtorotatetheweldingheadinordertoadjusttheangleoftungsten.

lNumber13:‘Reduction’Button

Press‘Reduction’button,theweldingmachinemaystopgraduallyinashorttime.

lNumber14:‘Stop’Button

Incaseoftheemergencyhappens,ifthereisnotimetoturnoffthepower,press"stop"button,theweldingwillstopassoonaspossible.

lNumber15:‘Start’Button

Whetherinteststatusorweldingstate,pressthe"start"button,touchscreenwillbe10curve,showingFIGweldingcurrent,pulsecurrent(relativetoturntodifferentanglesshowscorrespondingvalue),wirefeedingspeed,rotaryspeedprograminformation.

nApplicableindustries

Petrochemical,boiler,refrigeration,medicine,aviation,pressurevessel,ship,foodmachinery,atomicenergyetc

nApplicablescope

Applytotubediameterfrom16mm-300mm,fortube-pipe,tube-elbow,tube-flanges,tube-Plug,etc.weldingmaterialscontaincarbonsteel,alloysteel,stainlesssteel,etc.usedfillingwireornotfillingwirebuttwelding.

Aselectionof5weldingheadstocovertheweldpipediarangefrom16mmto300mm:

KHGK16-40,KHGK36-90,KHGK70-160,KHGK140-230,KHGK210-300

MaintechnicalSpecification

|

Weldinghead |

KHGK16-40 |

KHGK36-90 |

KHGK70-160 |

KHGK140-230 |

KHGK210-300 |

||||

|

WeldingSpeed(r/min) |

|||||||||

|

SuitableDia.(mm) |

16~40 |

36~90 |

70~160 |

140~230 |

210~300 |

||||

|

ElectrodeDia.(mm) |

|||||||||

|

Swingingfunction |

|||||||||

|

Amplitude(mm) |

--- |

±8 |

±8 |

±8 |

±8 |

||||

|

Speed(mm/s) |

--- |

||||||||

|

Dwelltime(s) |

--- |

||||||||

|

ArcVoltageControl |

|||||||||

|

Amplitude(mm) |

--- |

8 |

8 |

8 |

8 |

||||

|

Speed(mm/s) |

--- |

||||||||

|

FillerWire |

|||||||||

|

WireDia.(mm) |

|||||||||

|

Speed(mm/min) |

0~1500 |

0~1500 |

0~1500 |

0~1500 |

0~1500 |

||||

|

PowerSource |

|||||||||

|

SettingRange(A) |

8~400 |

8~400 |

8~400 |

8~400 |

8~400 |

||||

Send product request

Other supplier products

| circular seam automatic welding machine | Brief Introduction: KHB Suspension Type Automatic Tube –Tube Sheet Pulse Tig Welding Machine is specially designed for the automatic all-posi... | |

| ircumferential seam automatic welding machine | KHGKSeriesoforbitpipe-tube automaticpulseargonarcweldingmachine Orbitalweldingmachine KHGKseriesisdesignedforallpositionautomaticweldingoftube-tu... | |

| KHGK Auto welding machine,TIG welding machine for pipe | KHGKSeriesoforbitpipe-tube automaticpulseargonarcweldingmachine Orbitalweldingmachine KHGKseriesisdesignedforallpositionautomaticweldingoftube-tu... | |

| girth seam automatic welding machine | ORBITALWELDINGMACHINE TheKHGCseriesisdesignedtoperformorbitalTIGweldsontubeandthinwallpipewithouttheneedforwirefeeding.Thesealedcavityisfilled... | |

| KHGC pipe welder, auto Tig welding machine, pipe welding equipment | ORBITALWELDINGMACHINE TheKHGCseriesisdesignedtoperformorbitalTIGweldsontubeandthinwallpipewithouttheneedforwirefeeding.Thesealedcavityisfilled... |

Same products

| Portable Handheld Fiber Laser Welder – Water Cooling for Industrial Use | Seller: Beijing JCZ Technology Co., Ltd | This portable handheld fiber laser welderis designed for industrial-grade welding operations. It ... | |

| Nozzle adjustment gauge | Seller: Weldy China Distributor Co.,LTD | Article127.826Item nameNozzle adjustment gaugeBrandWeldyCountry of originP.R. China | |

| Guide bar | Seller: Weldy China Distributor Co.,LTD | Article126.096Item nameGuide barBrandWeldyCountry of originP.R. China | |

| Heating wedge, stainless steel | Seller: Weldy China Distributor Co.,LTD | Article156.668Item nameHeating wedge, stainless steelVoltage230 VHot wedge materialStainless stee... | |

| Heating wedge, aluminum | Seller: Weldy China Distributor Co.,LTD | Article156.563Item nameHeating wedge, aluminumVoltage230 VHot wedge materialHard ematalised alumi... |