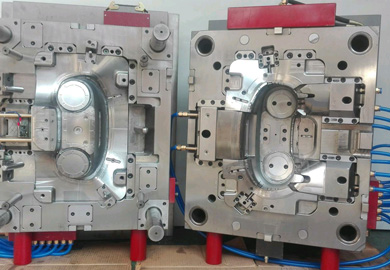

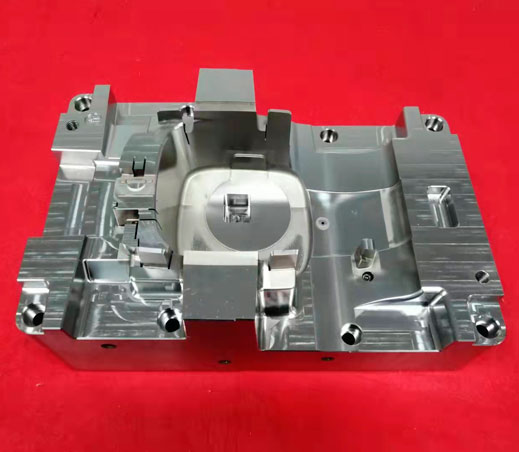

Medical Equipment Mould

Medical Equipment Mould

Medical device injection moldingis a process using medical-grade plastic materials to manufacture different durable medical parts and components. The medical device plastic injection molding process can provide benefits for a variety of applications such as medical enclosures, needles, surgical instruments, prosthetics, and so on.

GM-TECH is one of injection molding manufacturers. Our medical device molding parts and components with relatively low plastic injection molding cost are safe and reliable, which deserves your trust.

Features of Medical Equipment Mould

Due to the high-quality materials, the medical device injection molding process can be performed smoothly and safely, which ensures the medical parts are durable and reliable. These medical-grade plastics have become the ideal material for different kinds of electronic medical equipment. Several features that our medical device plastic injection molding service can provide, include:

Reduced weight

Increased functionality

Lower cost

The decreased burden of sterilization

The Specification of Medical Equipment Mould

|

Part material |

ABS |

|

Cavity |

1 + 1 |

|

Mould accuracy |

+ / - 0.02mm |

|

Mould steel |

H13 |

|

Mouldbase steel |

|

|

Mould life |

100W |

|

Mould standard |

DME |

|

Mould structure |

1 slides |

|

Exporting country |

USA |

|

Leadtime |

5 weeks |

|

Mould quality customer satisfaction |

|

|

FAI pass rate |

|

|

Project cooperation service customer satisfaction |

How does Medical Equipment Mould Work?

When it comes to the working principle of medical device molding, it is inevitable to mention the medical process machine. The medical device precision injection molding machine consists of three parts, namely the feed hopper, the screw, and the heated barrel.

When the feed hopper receives the plastic granules, it uses the frictional action of the screw to create heat. Once the plastic reaches the correct temperature, it is then injected into the medical device plastic injection mold cavity. Finally, it gradually keeps cooling and takes the shape of the designed medical device molding part.

If you want to buy high quality plastic moulded products, please contact us.

Send product request

Other supplier products

| Automotive Part | Automotive Part As the foundation of the automotive industry, injection moulding automotive partsare necessary factors to support the sustainabl... | |

| 2K Mould | 2k mouldingis a manufacturing process that refers to molding two materials or colors into one plastic part. This technology combines two materia... | |

| Mould Slide | GM-TECH, a plastic injection manufacturer, has been manufacturing tools for injection molding of plastics for various industries for more than 10 y... | |

| Mould Component | Mould Component Mould Componentsare also a part of the mould. GM-TECH not only produces precision moulds but also provides customers with high-pre... | |

| Automotive Part | As the foundation of the automotive industry, injection molding automotive parts are necessary factors to support the sustainable and healthy devel... |

Same products

| For Mercedes-Benz-C-206 Modified Bumper Mould | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Taizhou Huangyan Chenpeng Mold Co., Ltd. is a professionalwholesale Mercedes-Benz-C-206 Modified ... | |

| Front Bumper Lower Lip Mould For 2021 Honda CRV | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Introducing the for 2021 Honda CRV Front Bumper Lower Lip Mould: Elevate Your Driving Experienc... | |

| Bottle cap mold | Seller: Taizhou Huangyan Yongsheng Mould Co., Ltd. | Taizhou Yongsheng Mould Co., Ltd. can produce cap moulds ()within 64 cavities. The hot runner or ... | |

| Plastic Injection Mould For 2009 Audi A5 Front Bumper | Seller: Taizhou Huangyan Chenpeng Mould Co., Ltd. | Our Advantage:1.We have developed about 1000 PCS bumper mould since we founded.2.Our company's mo... | |

| Double Color Mold For Car Head Lighting Two-Shot Mold | Seller: Taizhou Toolsong Mould Co., Ltd. | Double Color Mold For Car Head Lighting Two-Shot Mold Double color lens mold for car head lighti... |