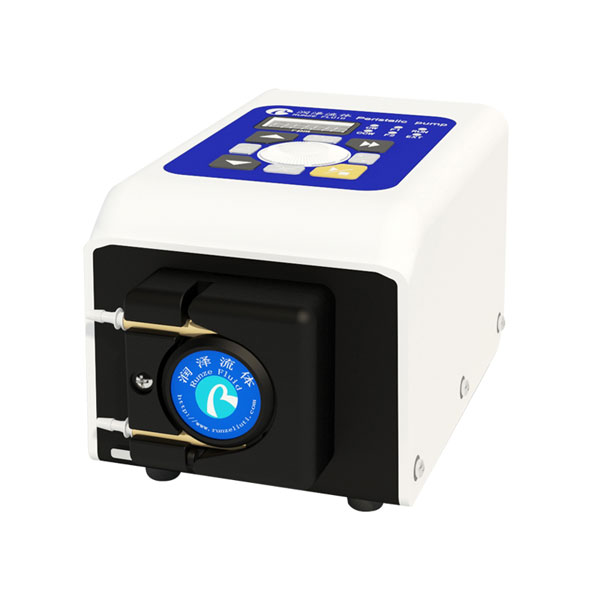

Miniature Peristaltic Pump

Miniature Peristaltic Pumpshead is very high cost performance model for small flow rate applications like the micro peristaltic pumps, small layout, 4 rollers structure and easy tubing replacement make it very welcomed by medical and lab equipment, flexible block designs enable it self-adapt to different tube sizes in a wide range.

Specification of

|

Model No. |

RZ1030-4 |

|

Pump Roller |

POM 4 rollers |

|

Pump Head |

ABS engineering plastic |

|

Fast Tubing |

YES |

|

Pump Color |

Black |

|

Compatible Motor |

Stepper motor/DC motor |

|

Motor Speed |

0-500rpm |

|

Flow Range |

0-170ml/min |

|

Tubing Size |

|

|

Tubing Life |

Silicone≥200H BPT Rubber≥1000H |

|

Pressure Rating |

Up to 2 bar(30psi) |

|

Working Environment |

0-40℃, <80% non-condensing |

|

Max DB |

65db |

|

Suction |

5 meters |

|

Head |

8 meters |

|

Dimension (L*W*H) |

57*65*23mm |

|

Net Weight |

58g |

Fitting Peristaltic Tubing of Miniature Peristaltic Pump

|

Picture |

Material |

Features |

Service Life |

|

Silicone |

Food grade, High flexibility Temp. range -4℃ - +180℃ For non-corrosive liquid |

≥200h |

|

|

Pharmed BPT |

Saint-Gobain, FDA standard Temp. range -51℃- +132℃ Anti weak acid and alkali |

≥1000h |

|

|

Viton |

MasterFlex, FDA Standard Temp. range -20℃- +260℃ Anti strong acid and alkali |

≥1000h |

How Do Micro Peristaltic Pumps Work?

The mini peristaltic pumps are low-pressure product pumps, the general working pressure does not exceed 0.7Mpa, and the large peristaltic pump (hose pump) can reach more than 1Mpa. The miniature peristaltic pump alternately squeezes and releases the elastic delivery hose of the pump, so that the peristaltic pump draws fluid. Just like pinching and squeezing a hose with two fingers, the hose moves with the fingers, and the liquid creates a negative pressure in the hose. There are many types of fluids transmitted by micro peristaltic pumps, not only fluids with particles, but also fluids with strong acids, strong bases and strong organic solvents. You only need to choose a hose suitable for the fluid.

What Are the Advantages of Using Micro Peristaltic Pumps?

How to Maintain a Micro Peristaltic Pump?

The composition of the mini peristaltic pumps is divided into three components: the driver, the pump head, and the hose. During use, the hose is consumable and needs to be replaced regularly. The driver and pump head are maintenance-free parts, and only need to be dry and cleaned daily. Work without special maintenance.

In the use of the miniature peristaltic pump head, the common damages include the following situations, which need to be paid attention to during use: First, the speed is too high, exceeding the design speed requirements of the pump head; Second, accidental fall from high altitude, resulting in deformation or damage of the pump head; Third, the leakage of the hose causes the liquid to enter the rollers of the pump head and the main shaft bearing, and damage the bearings.

Send product request

Other supplier products

| 12v Peristaltic Pump | 12v peristaltic pumpis available of 12V and 24V DC motor for specific system requirement, the peristaltic water pump DC motor can work immediately ... | |

| Multi Channel Syringe Pump | Multi Syringe Pumpis a precision syringe pump specially designed for high precision liquid handling with a small footprint applied in limited space... | |

| Peristaltic Pump Head | Peristaltic Pump Headsis the most important part for a full unit peristaltic liquid pump, it is responsible to drive the suitable tubes to reach th... | |

| Laboratory Peristaltic Pump | Laboratory Peristaltic Pump is a bench-top type peristaltic liquid pump suitable for laboratories and production line to filling bottles or fluid m... | |

| Laboratory Peristaltic Pump | Laboratory Peristaltic Pump is a bench-top type peristaltic liquid pump suitable for laboratories and production line to filling bottles or fluid m... |