Electrostatic Decay Tester

The Electrostatic Decay Tester is professionally designed to evaluate the static electricity attenuation characteristics of textile and non-textile materials. It is used to measure corona discharge time, static voltage attenuation half-life, static decay curves, and other electrostatic properties.

The instrument provides quantitative analysis of electrostatic diffusibility, enabling accurate assessment of anti-static performance for research, quality control, and compliance testing.

Application

The Electrostatic Decay Tester is applicable to electrostatic performance evaluation across the following industries and products:

(1) Textile Industry: fibers, filaments, yarns, woven fabrics, knitted fabrics, nonwoven fabrics, functional textiles

(2) Apparel and Garment Industry: anti-static workwear, protective clothing, cleanroom garments, sportswear

(3) Medical and Healthcare Industry: surgical gowns, medical protective clothing, medical nonwoven materials

(4) Industrial and Technical Textiles: filter media, conveyor belts, reinforcement fabrics, industrial fabrics

(5) Electronics and Semiconductor Industry: ESD fabrics, anti-static curtains, packaging materials, cleanroom textiles

(6) Polymer and Plastic Industry: plastic films, sheets, plates, composite materials

(7) Automotive and Aerospace Industry: interior fabrics, seat materials, insulation materials, composite panels

(8) Research and Quality Inspection: laboratory test specimens, standard verification materials, R&D samples

Standards

The instrument complies with and can be applied to the following standards (including but not limited to):

(1) JIS L 1094 – Testing Methods for Electrostatic Properties of Textiles

(2) GB/T 12703 – Textiles — Evaluation of Electrostatic Properties

(3) ISO 18080 – Textiles — Test method for electrostatic properties

(4) AATCC 76 – Electrical Resistivity of Fabrics

(5) AATCC 84 – Electrical Resistance of Conductive Yarns

Features

(1) Integrated analysis and calculation unit capable of automatically computing voltage decay half-life from the static decay curve

(2) One-touch automatic measurement by connecting the analyzer and host meter

(3) Separation design of tester and controller for safe and convenient operation

(4) Digital voltmeter for direct display of test results

(5) Automatic shutdown function for high voltage and motor protection

(6) Optional data analysis software for detailed curve analysis and result reporting

(7) Stable and repeatable testing performance suitable for laboratory and industrial use

Technical Parameters

| Item | Specification |

|---|---|

| Electrostatic Voltage Measuring Range | 0 – 10 kV |

| Half-life Time Range | 0 – 99.99 h |

| Rotation Speed | 1500 RPM |

| Discharge Time | 0 – 99.99 s (standard test time: 30 ± 0.1 s) |

| Discharge Distance (Needle Electrode to Specimen) | 20 mm |

| Measurement Distance (Probe to Specimen) | 15 mm |

| Sample Size | 60 mm × 80 mm |

| Power Supply | AC 220 V, 50 Hz |

| Power Consumption | 1.5 kW |

Accessories

Main testing unit

Analyzer and controller module

Needle electrode assembly

Digital voltmeter

Sample holder

Power cable

Operation manual

Calibration certificate

Test Procedures

(1) Prepare the specimen according to the applicable standard

(2) Ensure the oil cylinder is filled with transformer oil before testing

(3) Power on the instrument and perform voltage calibration if required

(4) Place the specimen on the sample holder

(5) Set the test parameters and discharge time

(6) Start the test using one-touch operation

(7) Record voltage decay curve, half-life time, and related parameters

Maintenance Information

(1) Verify electrostatic voltage calibration before routine use

(2) Ensure the oil cylinder remains properly filled with transformer oil

(3) Clean electrodes and sample holder regularly to maintain accuracy

(4) Inspect electrical connections and safety protections periodically

(5) Store the instrument in a dry, dust-free laboratory environment

Send product request

Other supplier products

| Friction and wear testing machine | Standards ASTM G99-04 ASTM G77-16 ISO 9352:1995 GB/T 12444-2006 GB/T 12607-2007 GB/T 1865-2009 Application field Petrochemical: Used to ass... | |

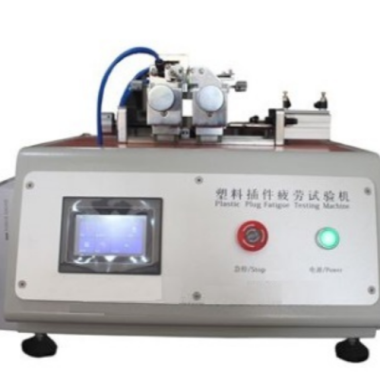

| Bag Plastic Buckle Durability Tester | It is mainly used to test the service life of plastic plug-ins in luggage accessories. Applications This machine simulates the use of plastic cla... | |

| Hot Cold Chamber | Features and Benefits 1.Hotcoldchambercan range from very low temperatures ( -70 ° C or lower) to high temperatures (+180 ° C or higher) t... | |

| Qinsun Xenotest 220 | Standards ISO 105-B02: Lightfastness testing for colored textiles. AATCC TM16 (Option 3): Accelerated weathering for textiles under controlled co... | |

| Automatic Cap Torque Tester | A Bottle Cap Torque Tester is a specialized device used to measure the torque applied to bottle caps during sealing or opening processes. Its prima... |

Same products

| Full-Body Garment Stress Tester,FZ/T 70015 | Seller: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Seller: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Seller: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Seller: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Seller: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |