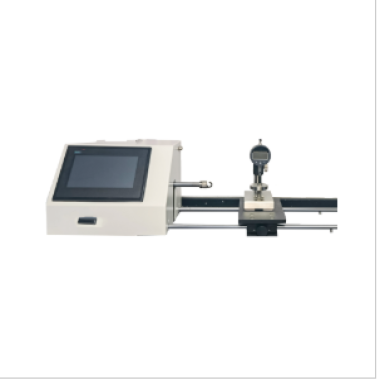

Medical Suture Line Diameter Tester

The Medical Suture Thread Diameter Tester is a specialized testing equipment used for measuring the diameter or linear diameter of medical suture threads.

Applications

Quality Control: The medical suture thread diameter tester plays a crucial role in the quality control of medical devices. By accurately measuring the diameter of suture threads, it ensures that products meet relevant medical standards and specification requirements, thereby improving the quality and safety of medical devices. Manufacturer Inspection: During the production process, manufacturers need to conduct strict quality inspections on each batch of suture threads. The thread diameter tester can monitor the changes in thread diameter in real - time, promptly detect and correct production deviations, and improve production efficiency and product quality. Third - Party Inspection: Independent third - party testing laboratories are responsible for conducting random quality inspections and verifications on suture threads sold in the market. The high - precision data provided by the thread diameter tester can serve as a reliable basis for test reports, ensuring the safety and effectiveness of products during use. Product R & D: In the process of developing new suture thread products, R & D personnel need to repeatedly verify and adjust product specifications. The thread diameter tester can provide accurate thread diameter measurement data, helping R & D personnel optimize the design and improve product performance.

Standards

The medical suture thread diameter tester needs to comply with relevant medical industry standards, such as YY 1116 - 2020Absorbable Surgical Suture and YY 0167 - 2020 Non - absorbable Surgical Suture. These standards specify in detail the requirements for the technical parameters, testing methods, and measurement accuracy of the suture thread diameter tester, ensuring the accuracy and reliability of measurement results.

Features

1. Compliance

Execution Standards: Designed and manufactured according to the wire diameter testing clauses in YY1116-2020 "Absorbable Surgical Sutures" and YY0167-2020 "Non-absorbable Surgical Sutures".

Allows for measurement at multiple positions, including 1/4. 1/2. and 3/4 of the length; for multi-strand sutures with specifications greater than metric 2. the suture can be rotated 90° for measurement without disassembly.

2. Stability

Uses a grating displacement sensor instead of a micrometer, providing accuracy to one ten-thousandth and excellent stability.

3. Convenience

Manual sample loading, electric tensioning, and multi-point automatic measurement.

To address the issue of changing weights for each specification, it innovatively uses a high-precision force sensor to automatically set the tension force, making operation simple.

Equipped with quick mechanical buttons for testing and stopping, allowing for one-button testing and pausing.

4. Intelligence

A 7-inch color touch screen combined with intelligent data processing functions provides users with a comfortable and smooth operating experience.

Touch screen operation: Nominal specification, test load, printing, testing, left movement, right movement, time, calibration.

Technical Parameters

| Serial No. | Parameter Item | Parameter Details |

|---|---|---|

| 1 | Minimum Division Value | Not exceeding 0.002mm (some high-precision devices can reach 0.001mm), ensuring precise suture thread diameter measurement |

| 2 | Base Diameter | Usually greater than 50mm, providing stable basic support for measurement |

| 3 | Pressing Plate Diameter | 12.70mm±0.02mm, used to apply pressure to the suture thread for diameter measurement |

| 4 | Presser Foot Load | Varies by suture thread specifications:- For specifications > nominal size 0.4 (or 8-0): 210g±3g- For specifications ≤ the above size: ≤60g |

| 5 | Calibration Difference and Parallelism Difference | Not greater than 0.005mm (between pressing plate surface and base), ensuring measurement accuracy |

Accessoriess

One main unit, one certificate of conformity, accompanying fixtures, one instruction manual, and one roll of printing paper.

Test Procedures

1. Preparation Before Operation

Equipment and Environment Check:

Connect the power supply (suitable for wide voltage range), start the equipment and confirm that the operating interface is functioning correctly; place the equipment in a standard testing environment of **22±2℃ and 50±5% humidity**, ensuring the workbench is stable and vibration-free.

Sample Preparation:

Select suture samples that meet the standards of "YY 1116-2020 Absorbable Surgical Sutures" and "YY 0167-2020 Non-absorbable Surgical Sutures," cut them to a length of 10-15cm, ensuring the sutures are clean, untwisted, and undamaged.

Equipment Pre-check:

Confirm the condition of the components, including the press plate diameter (12.70mm±0.02mm) and base diameter (≥50mm), ensuring there is no wear or deformation.

2. Equipment Calibration (Ensuring Measurement Accuracy)

Baseline Calibration:

In the unloaded state, verify the "calibration difference and parallelism difference between the press plate surface and the base," ensuring the error is ≤0.005mm; calibrate the minimum division value (typically ≤0.002mm, high-precision models ≤0.001mm) using the equipment's built-in calibration program.

Press Foot Load Calibration:

Set the press foot load according to the suture specifications:

Suture specifications > nominal 0.4 (or 8-0): Calibration load is 210g±3g;

Specifications ≤ nominal 0.4 (or 8-0): Calibration load ≤60g.

3. Sample Installation

Place the suture naturally in the center of the base, ensuring the suture is not stretched or twisted; adjust the position of the press plate so that it is aligned with the area of the suture to be measured, avoiding contact between the suture and other parts of the equipment.

4. Parameter Settings

Select the corresponding standard (YY 1116-2020/YY 0167-2020) through the operating interface and set:

Measurement mode (single measurement/multi-position average measurement);

Press foot load matching the sample specifications;

Minimum division value (select 0.001mm/0.002mm accuracy as needed). 5. Test Execution

After confirming the parameters are correct, start the test; the device automatically drives the pressure plate to apply the set load to the suture, and simultaneously collects diameter data.

It is recommended to measure 3-5 different positions on a single suture to obtain multiple data sets to improve result stability.

6. Data Processing and Application

The device automatically calculates the average measurement value and displays the individual data sets and the average;

A report is generated containing "sample information, measurement data, calibration records, and compliance with standards," which is used for:

Quality control: verifying whether the suture diameter meets medical standards;

Production testing: real-time monitoring of diameter deviations in batch products;

Third-party inspection: providing high-precision data for compliance verification of products in the market.

7. Post-Test Maintenance

Turn off the device power, and clean any remaining suture fibers from the base and pressure plate surface;

Record the device usage status, and regularly re-examine the pressure plate wear and sensor accuracy to ensure the long-term stable operation of the equipment.

Send product request

Other supplier products

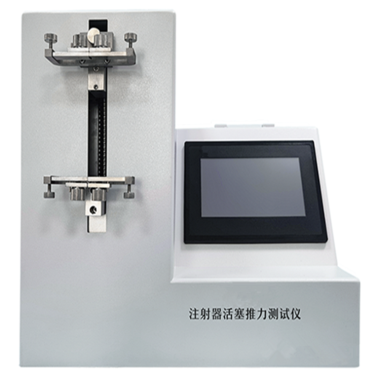

| Syringe piston thrust tester | Product introduction The syringe piston thrust tester is a kind of high precision and high stability measuring equipment, which is used to measure... | |

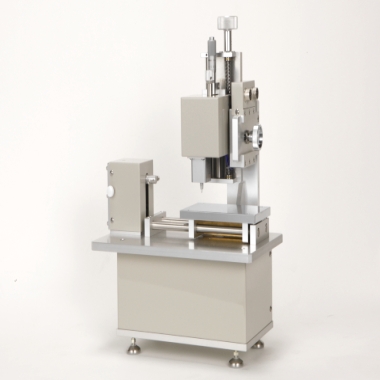

| Rubber non-rotor vulcanization Tester | The Rubber Non-Rotor Vulcanization Tester is a precision instrument designed for the rubber processing industry to monitor and control rubber mater... | |

| Putty sanding meter | Standard GB/T 1770 YC/T 315-2009 GB/T 1749-2025 Technical parameters The technical parameters of the putty sanding tester may vary from model ... | |

| Full Notch Creep Tester | Standard ISO 16770: Exclusively designed for full-notch creep testing (FNCT) of thermoplastics under sustained stress. ASTM D2990: Configurable f... | |

| Medical glove water-impermeability tester | The medical glove water-impermeability tester is used to determine the water-impermeability performance of medical rubber examination gloves, inclu... |

Same products

| Gas Oxidizing Property Tester | Seller: Standard International Group (HK) Limited | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylind... | |

| Battery Powder Compaction Density Measurement System | Seller: Standard International Group (HK) Limited | The Battery Powder Compaction Density Measurement System is a precision testing system designed... | |

| Battery Powder resistance tester | Seller: Standard International Group (HK) Limited | The Powder Resistivity Meter is a precision testing system designed to measure electrical resisti... | |

| KES-SESRU surface roughness/friction tester | Seller: Standard International Group (HK) Limited | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans ... | |

| Air Permeability Tester STD- F8 | Seller: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... |