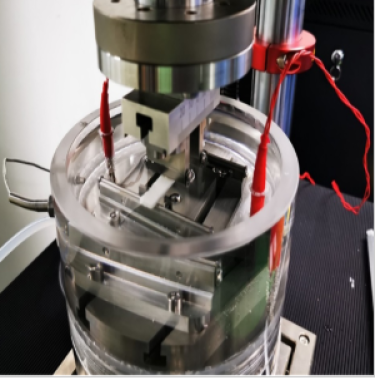

Battery Powder resistance tester

The Powder Resistivity Meter is a precision testing system designed to measure electrical resistivity, conductivity, and related properties of powders under controlled pressure and environmental conditions. It is suitable for conductive and insulating powders, including battery cathodes, anodes, solid-state electrolytes, and conductive additives. The system enables automated, high-accuracy testing for R&D, quality control, and material optimization applications.

Application

(1) Measurement of powder resistivity and conductivity for lithium-ion, sodium-ion, and solid-state battery materials (e.g., LCO, NCM, LFP, graphite).

(2) Evaluation of conductive additives and composite powders for battery electrodes.

(3) Determination of powder compacted density and mechanical response under controlled pressure.

(4) Assessment of solid-state electrolyte powders and electrical insulation properties.

(5) Material R&D for optimizing electrode mixing, compaction, and battery performance.

(6) Quality control of powder batches for consistency and reproducibility.

(7) Simulation of real-world compaction processes through pressure step, single-point unloading, and steady-state unloading tests.

(8) Data-driven analysis for battery manufacturing and research using exported CSV/PDF files or integration with LabVIEW, MATLAB, or Python.

Standards

(1) YS/T 587.6-2006 – Test methods for battery powder resistivity (China).

(2) GB/T 24525-2009 – General methods for measuring electrical resistivity of powders.

(3) GB/T 30835-2014 – Technical specification for battery powder conductivity testing.

Features

(1) Dual-probe compatibility: Switch seamlessly between four-point probe (low-resistance powders) and two-point probe (high-resistance powders).

(2) Ultra-wide measurement range: Pressure up to 350 MPa and resistance up to 1200 MΩ, suitable for conductive to insulating powders.

(3) Fully automated operation: Programmable software allows one-click testing with adjustable pressure, duration, and sampling rate.

(4) Real-time monitoring: Measures pressure, stress, temperature, humidity, thickness, resistance, resistivity, conductivity, and tapped density; generates dynamic curves and auto-saves reports.

(5) Versatile testing modes: Pressure step, single-point unloading, and steady-state unloading for realistic compaction simulations.

(6) High-precision control: Pressure accuracy ±0.5% FS; laser-based thickness measurement ±1 μm.

(7) Environmental compensation: Built-in temperature (-20°C to 150°C) and humidity (10%–95% RH) sensors.

(8) Certified calibration: NIST-traceable thickness and resistance blocks ensure accurate measurement and compliance.

(9) Ergonomic design: Compact footprint with touchscreen interface and safety interlocks for hazardous powder testing.

Parameters

| Parameter | Specification |

|---|---|

| Pressure Range | 0–350 MPa (adjustable increments) |

| Resistance Measurement | 1 μΩ–1200 MΩ (10 nΩ resolution) |

| Thickness Accuracy | ±1 μm (laser sensor) |

| Temperature Range | -20°C to 150°C (±0.5°C accuracy) |

| Humidity Range | 10%–95% RH (±3% accuracy) |

| Data Interface | USB 3.0, Ethernet, RS-232 |

| Power Supply | 100–240 V AC, 50/60 Hz |

| Dimensions (W×D×H) | 450 × 550 × 600 mm |

Accessories

(1) Main Unit: Powder Resistivity Meter with integrated safety enclosure.

(2) Software Suite: Multi-language GUI with data analysis tools.

(3) Probes: Two interchangeable probe sets (four-point and two-point).

(4) Calibration Kits: Thickness calibration block (certified) and resistance standards (10 Ω, 1 kΩ, 100 kΩ).

(5) Testing Jigs: Customizable powder cells for varying sample volumes.

(6) User Manual: Multilingual PDF with operation and maintenance instructions.

Test Procedures

(1) Place the powder sample into the designated test cell and select the appropriate probe.

(2) Set test parameters in the software, including pressure range, duration, and measurement mode.

(3) Start the test; the system automatically applies pressure and records electrical and environmental parameters in real time.

(4) Analyze data via software; export results in CSV/PDF format or integrate with analytics tools for further evaluation.

Maintenance Information

(1) Inspect probes, calibration blocks, and test cells regularly for wear or contamination.

(2) Calibrate thickness and resistance measurement systems periodically using certified standards.

(3) Keep the control system, touchscreen interface, and software environment clean and dry.

(4) Verify safety interlocks and emergency stop functions before testing powders.

(5) Lubricate or maintain any moving mechanical parts according to manufacturer recommendations.

Send product request

Other supplier products

| Wrinkle Recovery Tester 丨Wrinkle Recovery Test mechine | Standards AATCC 128, ISO 9867, ENKA 3061 Applications AATCC Wrinkle Recovery Tester is used to determine a fabric's ability to recover after wri... | |

| Bonding Strength Measuring Instrument | The tack - holding tester, also known as the tack - holding property tester, tack - holding force tester, or holding - power tester, is a device sp... | |

| Fiber Blend Ratio meter | Product Introduction: It is used to measure the resistance value with a certain density under a certain geometry, and then converts it into the sp... | |

| Absorbable Bone - connecting Plates Four - point Bending Tester | Standard ASTM F2119: Standard test method for constant load testing of bioabsorbable screws and washers, applicable to bending performance evalu... | |

| Photography Testing Light Chamber | Standard ISO 12233: Compliant with SFR (Spatial Frequency Response) testing for lens resolution. IEC 62679: Photometric requirements for video ca... |

Same products

| Thrust Bearing Rolling Friction and Wear Testing Machine | Seller: Standard International Group (HK) Limited | Applicable Standards: ASTM D3702 ASTM G99 ASTM G77 ISO 18535 Product Advantages: Simulates ... | |

| Falling Sand Abrasion Test machine | Seller: Standard International Group (HK) Limited | The sand abrasion tester is a specialized testing device used to evaluate the abrasion resistance... | |

| Conveyor Belt Drum Friction Testing Machine | Seller: Standard International Group (HK) Limited | Main Purposes of Conveyor Belt Drum Friction Testing Machine The conveyor belt drum friction tes... | |

| Dry Sand Rubber Wheel Wear Tester | Seller: Standard International Group (HK) Limited | The dry sand rubber wheel abrasion tester is mainly used to test the abrasion resistance of mater... | |

| Sliding Bearing Fatigue Testing Machine | Seller: Standard International Group (HK) Limited | The sliding bearing fatigue testing machine is an important testing device, mainly used to evalua... |