Flotation cell (total cross-section, air-lift, micro bubble)

Introduction

This flotation cell is invented by our company and has been applied for a patent. Compared with the traditional flotation cell, our equipment with the agitation.

Features

Many one-way abrasion-resistant rubber valves are equipped at the bottom of flotation cell .

The production expense and installed power are separately reduced by 70% and 60% compared to that of the traditional equipment.

Dust removal unit, screening factory and screening equipments are leaved out, which reduce civil engineering investment, the floor area and the cost of labor power and management.

The max feeding size is 160mm.

Application

It is used for coarse grinding after coarse crushing.

Working principle

The essential component is a cylinder with bigger diameter and smaller length which is slowly revolved via transmission machinery. Materials are fed into central sleeve where ores are fully grinded due to the falling impact and autogenous grinding. Ore materials, which are eligible for the particle size standard and pass through grid plate, are discharged from another side of central sleeve, with the aid of overflow water.

Technical parameter

Number Model Capacity(t/d) ·Diameter

(m) Height(m) Volume(m³) Airsuction

amount(m³/min) Air

pressure(Kpa) Weight(t)

1 XQFφ1000×7000 45 1.0 7.0 4.87 0.94 120.90 3.5

2 XQFφ1000×6400 40 1.0 6.4 4.40 0.94 109.20 3.1

3 XQFφ1000×5800 39 1.0 5.8 3.93 0.94 97.50 2.9

4 XQFφ1500×7000 100 1.5 7.0 10.96 2.12 120.90 5.4

5 XQFφ1500×6400 98 1.5 6.4 9.90 2.12 109.20 4.9

6 XQFφ1500×5800 86 1.5 5.8 8.84 2.12 97.50 4.5

7 XQFφ2000×7000 190 2.0 7.0 19.48 3.77 120.90 7.5

8 XQFφ2000×6400 170 2.0 6.4 17.59 3.77 109.20 6.8

9 XQFφ2000×5800 150 2.0 5.8 15.71 3.77 97.50 6.2

10 XQFφ2500×7000 300 2.5 7.0 30.43 5.89 120.90 9.7

11 XQFφ2500×6400 270 2.5 6.4 27.49 5.89 109.20 8.8

12 XQFφ2500×5800 240 2.5 5.8 24.54 5.89 97.50 8

13 XQFφ3000×7000 420 3.0 7.0 43.83 8.48 120.90 12

14 XQFφ3000×6400 370 3.0 6.4 39.58 8.48 109.20 10.9

15 XQFφ3000×5800 350 3.0 5.8 35.34 8.48 97.50 9.9

16 XQFφ3500×7000 580 3.5 7.0 59.65 11.55 120.90 14.50

17 XQFφ3500×6400 520 3.5 6.4 53.88 11.55 109.20 13.20

18 XQFφ3500×5800 480 3.5 5.8 48.11 11.55 97.50 12.00

19 XQFφ4000×7000 780 4.0 7.0 77.91 15.08 120.90 16.00

20 XQFφ4000×6400 700 4.0 6.4 70.37 15.08 109.20 15.20

21 XQFφ4000×5800 620 4.0 5.8 62.83 15.08 97.50 14.40

Other supplier products

|

|

Electromagnetic iron remover |

Introduction

Electromagnetic iron remover is custom designed for the removal of tramp iron from magnetic material like iron ore, sinter ore, pelle... |

|

|

Dry magnetic separator |

Introduction

Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force. Dry m... |

|

|

High efficiency agitating tank |

Introduction

High efficiency agitating tank is used for the pulp stirring before the flotation operations, make the pulp fully mixed with the phar... |

|

|

Jig |

Introduction

Jig concentrators are devices mainly used in the mining industry for mineral processing, to separate particles within the ore body, b... |

|

|

Circular vibrating screen |

Circular vibrating screen is a kind of effective vibrating screen with multi-layers. It employs cylindrical eccentric shaft vibration exciter and p... |

All supplier products

Same products

|

|

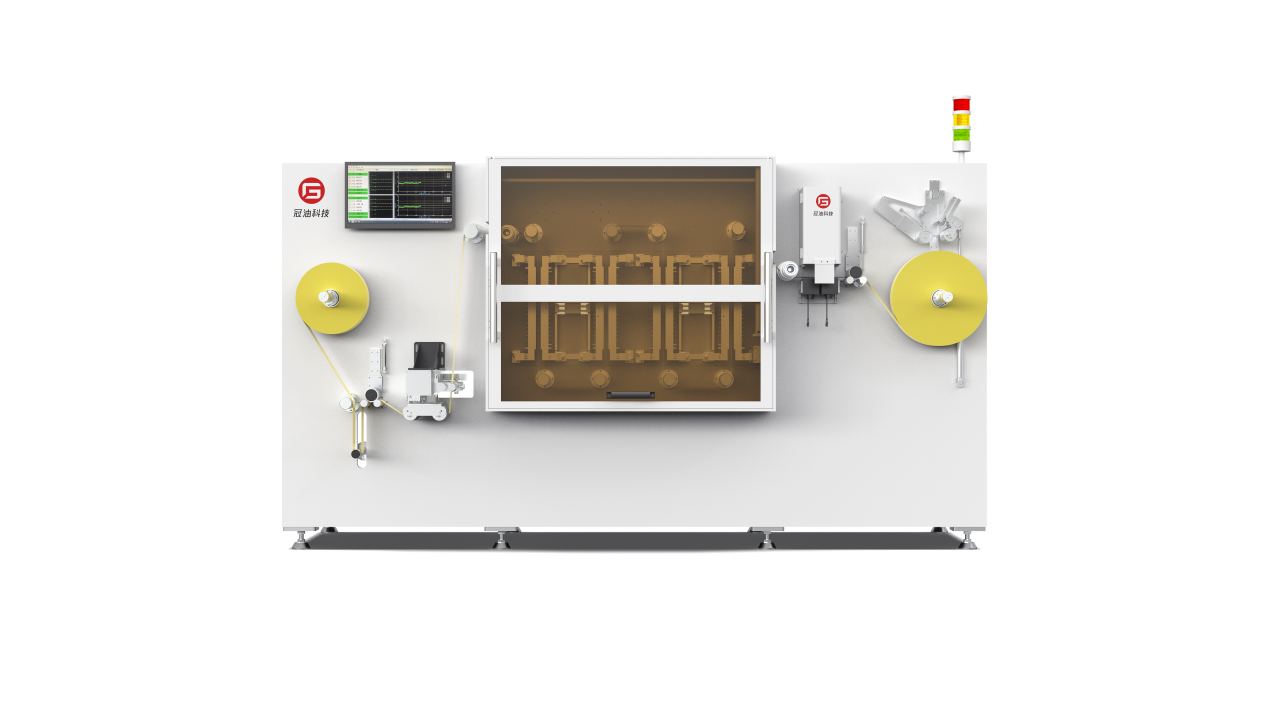

The Single Workstation Electrostatic Perforating Machine |

Seller: Wuhan Guan You Technology Co., Ltd. |

The single workstation electrostatic perforating machineis a professional cigarette paper static ... |

|

|

YZH WHEN1510 Stationary Pedestal Rockbreaker Boom |

Seller: Shandong Yirun Foundation Engineering Co., Ltd |

Below is a detailed introduction to the YZH WHEN1500 fixed hydraulic demolition arm, covering its... |

|

|

YZH WHEN1410 Stationary Pedestal Rockbreaker |

Seller: Shandong Yirun Foundation Engineering Co., Ltd |

YZH WHEN1410 Stationary Pedestal Rockbreaker is a specialized equipment designed for secondary cr... |

|

|

JY-160S2 Standard Plastic Injection Machine |

Seller: Dongguan Jieyang Machinery Co., Ltd |

Straight screw ejected assembly.

Two(three)-phase temperature, ejected speed, backing pressure a... |

|

|

WPC Terrace panel extrusion line |

Seller: Qingdao Trusty Plastic Machinery Co.,Ltd |

Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... |