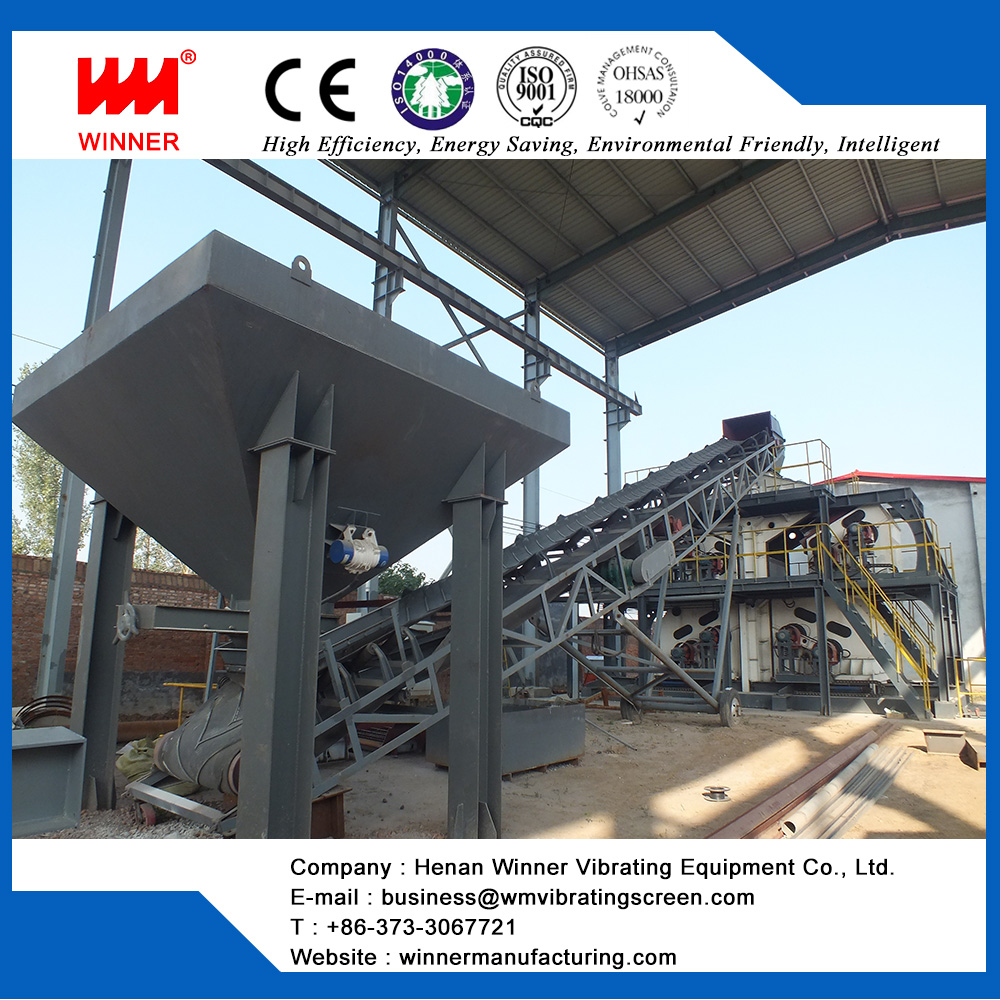

Linear vibrating screen for mining and metallurgy industry

Overview of Linear vibrating screen for mining and metallurgy industry:

Winner Group to achieve national environmental protection requirements,improve the sintering plant conditions of the environment, design a new ultra-environmental protection energy-saving double frequency vibrating screen, completely changed the sintering sieve site use environment, and effectively reduce the cost of sintering, to create green steel.

Advantages of Linear vibrating screen for mining and metallurgy industry:

Under the conditions of the same industrial and mining conditions, the weight of the compound frequency sieve is only 1/5 of that of the traditional elliptical sieve and 3/5 of the grizzly screen, so the double frequency screen is more than 1 times than the traditional oval sieve 1/3.

The single-layer double-surface sieve perforation rate can reach 40%, through the frequency, amplitude and other means to improve the effective screening efficiency of 90%.

Linear vibrating screen for mining and metallurgy industry using the overall replacement of the method, the replacement of a sieve 2 individuals only 2 hours will be able to resume production use, maintenance is simple, low-cost time.

Linear vibrating screen for mining and metallurgy industry adopts the sectional vibration mode, which is 2 - 3 times of the normal dynamic load when starting and stopping. It greatly reduces the cost of the infrastructure construction and has obvious economic benefits.

Linear vibrating screen for mining and metallurgy industry with Self-circulation cooling system, the exciter temperature can be controlled within 65 degrees, the bearing life is more than three times the traditional screen, the only oil required for the traditional screen sieve One-tenth of the machine.

According to customer requirements on the size of the material used in a variety of combinations, such as V-shaped, eight-shaped, laminated, etc. For viscous water-containing materials using multi-channel thin layer screening. For large capacity, double frequency granularity thickness probability screening principle, a variety of combinations to meet customer needs.

Applications of Linear vibrating screen for mining and metallurgy industry:

Mainly used in iron and steel enterprises solvent screening system (metallurgical industry sintering, blast furnace trough, coking, raw materials, etc.) and gravel aggregate system of construction industry. Using low amplitude, high frequency and other characteristics, for less than 5mm fine material screening is more excellent, but also to other industries, mainly for dry material screening. The sieve plate mainly bar, comb teeth, round steel welding, punching and so on.

Technical parameter table of Linear vibrating screen for mining and metallurgy industry:

|

Model |

Aperture size(mm) |

Motor speed r/min |

Motor power kw |

Amplitude mm |

Feed size mm |

Capacity t/h |

Outside Dimension(L*W*H) |

|

WFPS-40100 |

0-5 |

720-1440 |

8*18.5 |

6-9 |

≤5 |

0-600 |

10800*6208*5500 |

|

WFPS-36100 |

0-5 |

720-1440 |

8*15 |

6-9 |

≤5 |

0-520 |

10800*5908*5500 |

|

WFPS-33100 |

0-5 |

720-1440 |

8*15 |

6-9 |

≤5 |

0-450 |

10800*5908*5500 |

|

WFPS-3082 |

0-5 |

720-1440 |

6*11 |

6-9 |

≤5 |

0-360 |

9000*5208*5000 |

|

WFPS-2575 |

0-5 |

720-1440 |

6*7.5 |

6-9 |

≤5 |

0-280 |

8196*4650*4500 |

|

WFPS-2075 |

0-5 |

720-1440 |

6*5.5 |

6-9 |

≤5 |

0-230 |

8196*4150*4500 |

Send product request

Other supplier products

| Mining plane rotary vibrating sieve for food | Product overview of Mining plane rotary vibrating sieve for food: Mining plane rotary vibrating sieve for food is the most effective sieve screeni... | |

| Stock and stone crushing machine for waste recycling | Introduction Overview of Stock and stone crushing machine for waste recycling: Stock and stone crushing machine for waste recycling is the crusher... | |

| WYA series circular vibrating screen for mining | WYA series circular vibrating screen for mining Uses and characteristics of WYA series circular vibrating screen for mining: The circular traject... | |

| Rotary vibrating sieve for Chemical industry | Rotary vibrating sieve for Chemical industry Overview of Rotary vibrating sieve for Chemical industry: Rotary vibrating sieve for Chemical industr... | |

| Double frequency probability combination sieve | Double frequency probability combination sieve Principle of double frequency probability combination sieve: Overview of: Features: Under th... |

Same products

| YZH WHEN1510 Stationary Pedestal Rockbreaker Boom | Seller: Shandong Yirun Foundation Engineering Co., Ltd | Below is a detailed introduction to the YZH WHEN1500 fixed hydraulic demolition arm, covering its... | |

| YZH WHEN1410 Stationary Pedestal Rockbreaker | Seller: Shandong Yirun Foundation Engineering Co., Ltd | YZH WHEN1410 Stationary Pedestal Rockbreaker is a specialized equipment designed for secondary cr... | |

| YZH WHEN 1300 Stationary Pedestal Rockbreaker | Seller: Shandong Yirun Foundation Engineering Co., Ltd | The Features of the WHEN 1300 Stationary Pedestal Rockbreaker: Intelligent Multi-Mode Control: S... | |

| WHE1500 Pedestal Breaker Boom Systems | Seller: Shandong Yirun Foundation Engineering Co., Ltd | The Features of WHE1500 Pedestal Breaker Boom Systems: The WHE1500 Pedestal Breaker Boom System ... | |

| WHEN1850 boom breaker | Seller: Guangxi YZH Machinery Equipment Co.Ltd | A high-performance crushing equipment is crucial in the secondary crushing process of industries ... |