Measures to Deal Bag Pasting of Three-drum Dryer

To avoid the appearance of dew point, you should strictly control the feeding mount and sulfur content of fuels. To lower the temperature of dew point, you should lower the content of sulfur dioxide in the flue gas. Then, you should stabilize the speed balance between the material feeding, hot air and material discharging. In order to control the amount of wet materials in the rotary drum, you should control the temperature of exhausted gas higher about 15 ℃ than the dew-point temperature.

When the temperature of exhausted gas closes to the dew point, you should stop the feeding work. When the amount of wet materials decreases and temperature of air heating furnace increases, you can recover the drying work. When the three-drum dryer stops working, you should immediately remove the dust on the filter bag and dust hopper. In order to avoid the heat dissipation of precipitator, you should make the temperature of shell, dust hopper and air pipe be well kept.

According to the specialty of exhausted gas and type of precipitator, you should accordingly select the filter materials of glass fiber, Nekton or oilproof polyester. As a professionalsupplier of three-drum dryer, Fote Machinery has made the production for more than 30 years. Known as the NO.1 brand of China Mining Machinery, Fote Machinery can also produce other dryers like sand rotary dryer, coal slime dryer, industrial dryer and sawdust dryer machine, etc.

Interested in thethree-drum dryer of Fote Machinery? Please leave messages on our website or directly us. Surprises for you on website!

Fote Heavy Machinery:

Fote Official Website:

Send product request

Other supplier products

All supplier products

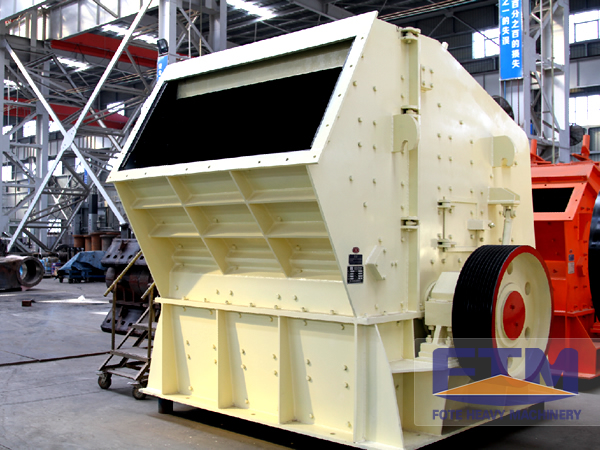

Different Stone Crushers in FTM Crusher Company

Based on the strong technological power and professional teams, FTM Crusher Company has produced many crushers like jaw crusher, impact crusher, ve...

What Should You Do After Running the VSI Crusher?

After turning on the VSI crusher, you should firstly make it run without loads, then do the feeding work after the above run is normal.Feeding work...

Briquetting Plant/Large Briquetting Plant

Introduction to Large Briquetting Plant

Major equipments: compound crusher, feeder, horizontal mixer, briquetting machine and dryer. Briquettes pla...

Gypsum Briquetting Machine of Fote Heavy Machinery

Most people think that it is easy to make the desulfurization gypsum. Actually, it is not as simple as you image. It is technical to produce the de...

Newly-type Working System of Hammer Mill Crusher

Known as the NO.1 brand of hammer mill crusher, FTM Crusher Company has produced the newly-type crushing system.The key part of this newly-type cru...

Same products

YZH WHEN1510 Stationary Pedestal Rockbreaker Boom

Seller: Shandong Yirun Foundation Engineering Co., Ltd

Below is a detailed introduction to the YZH WHEN1500 fixed hydraulic demolition arm, covering its...

YZH WHEN1410 Stationary Pedestal Rockbreaker

Seller: Shandong Yirun Foundation Engineering Co., Ltd

YZH WHEN1410 Stationary Pedestal Rockbreaker is a specialized equipment designed for secondary cr...

YZH WHEN 1300 Stationary Pedestal Rockbreaker

Seller: Shandong Yirun Foundation Engineering Co., Ltd

The Features of the WHEN 1300 Stationary Pedestal Rockbreaker:

Intelligent Multi-Mode Control: S...

WHE1500 Pedestal Breaker Boom Systems

Seller: Shandong Yirun Foundation Engineering Co., Ltd

The Features of WHE1500 Pedestal Breaker Boom Systems:

The WHE1500 Pedestal Breaker Boom System ...

WHEN1850 boom breaker

Seller: Guangxi YZH Machinery Equipment Co.Ltd

A high-performance crushing equipment is crucial in the secondary crushing process of industries ...