What Should You Do After Running the VSI Crusher?

After turning on the VSI crusher, you should firstly make it run without loads, then do the feeding work after the above run is normal.Feeding work should be at even. Size of raw materials should be smaller than the feeding mouth of VSI sand maker. For materials to be processed by VSI crusher, they should be pure without iron matters inside. Or else, key parts of VSI sand maker would be much easier to be worn out.

As to the sequence to make the shut-down work, it refers to stop the feeding work first. Discharging system can not be finished until all materials in crushing cavity are discharged out. Then, you can close the cooling system. As to the things for notice, they can be seen in the instructional books.If abnormal situation occurs, you can ask help from technicians and engineers of FTM Crusher Company. We will give you solutions as soon as possible.

Lubricating oil used for bearings should be added immediately and changed frequently. In order to immediately take the maintenance measures, control the changing period of easy-wearing parts and manage the accessories in order, you should frequently check the wearing situation of easy-wearing parts inVSI sand maker. As to the other items, they can be seen in the instructional books.

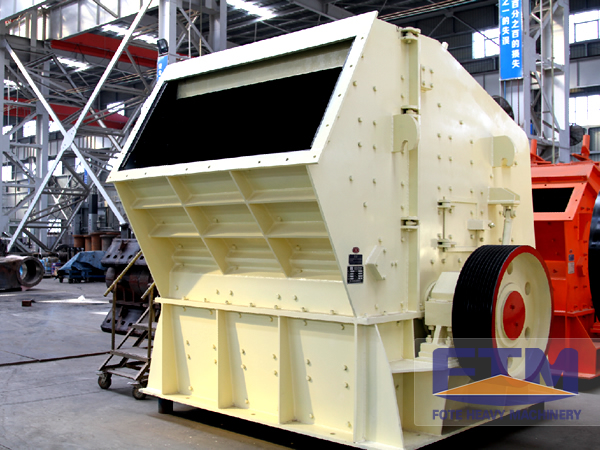

Doubtlessly, performance of VSI crusher is closely related with the structure and working principle. While, to a larger extent, the performance ofstone crushing machineis decided by the safe operation and frequent maintenance. Hope the above content can help you a lot.Enjoy the discounts on website!

Fote Heavy Machinery:

Fote Official Email:

Send product request

Other supplier products

All supplier products

What Should You Do After Running the VSI Crusher?

After turning on the VSI crusher, you should firstly make it run without loads, then do the feeding work after the above run is normal.Feeding work...

Skills to Install Bolts for Fixing Sludge dryer

To make the coal slime dryer be firmly fixed during the installation process, you need to learn some skills to install the foundation bolts. Hope t...

Maintenance Work for the FTM Straw Pellet Mill

As to the maintenance work for straw pellet mill, it should start from the first run of straw pellet mill. After each run, you should clean the str...

Points Related With Work of Hydraulic Cone Crusher

The matching of feeding size should be suitable. Service life of hydraulic cone crusher will be seriously influenced if materials are too coarse or...

Different Stone Crushers in FTM Crusher Company

Based on the strong technological power and professional teams, FTM Crusher Company has produced many crushers like jaw crusher, impact crusher, ve...

Same products

YZH WHEN1510 Stationary Pedestal Rockbreaker Boom

Seller: Shandong Yirun Foundation Engineering Co., Ltd

Below is a detailed introduction to the YZH WHEN1500 fixed hydraulic demolition arm, covering its...

YZH WHEN1410 Stationary Pedestal Rockbreaker

Seller: Shandong Yirun Foundation Engineering Co., Ltd

YZH WHEN1410 Stationary Pedestal Rockbreaker is a specialized equipment designed for secondary cr...

YZH WHEN 1300 Stationary Pedestal Rockbreaker

Seller: Shandong Yirun Foundation Engineering Co., Ltd

The Features of the WHEN 1300 Stationary Pedestal Rockbreaker:

Intelligent Multi-Mode Control: S...

WHE1500 Pedestal Breaker Boom Systems

Seller: Shandong Yirun Foundation Engineering Co., Ltd

The Features of WHE1500 Pedestal Breaker Boom Systems:

The WHE1500 Pedestal Breaker Boom System ...

WHEN1850 boom breaker

Seller: Guangxi YZH Machinery Equipment Co.Ltd

A high-performance crushing equipment is crucial in the secondary crushing process of industries ...