SPC/WPC/PVC Sheet Production Line/Poly-Vinyl Chloride Flooring Machine

Stone Plastic Composite SPC Flooring Extruder

SPC floor base sheet is a new and high-tech environmental protection material. It is the product of the mixing pvc resin and processing agent going through the extruding mould. SPC floor substrate board has the properties and features of non-toxic, no smell, anti-corrision, anti- weathering, waterproof etc. It is the perfect substitute for wood.SPC Flooring Base Sheet can be worked with the tools for wood material. It's easy for sawing, drilling, nailing, bonding and planning. Meanwhile, It is a kind of durable indoor and outdoor waterproof and anti-corrosion building material with excellent performance.

1.Design parameters

2.Equipment List & Quantity

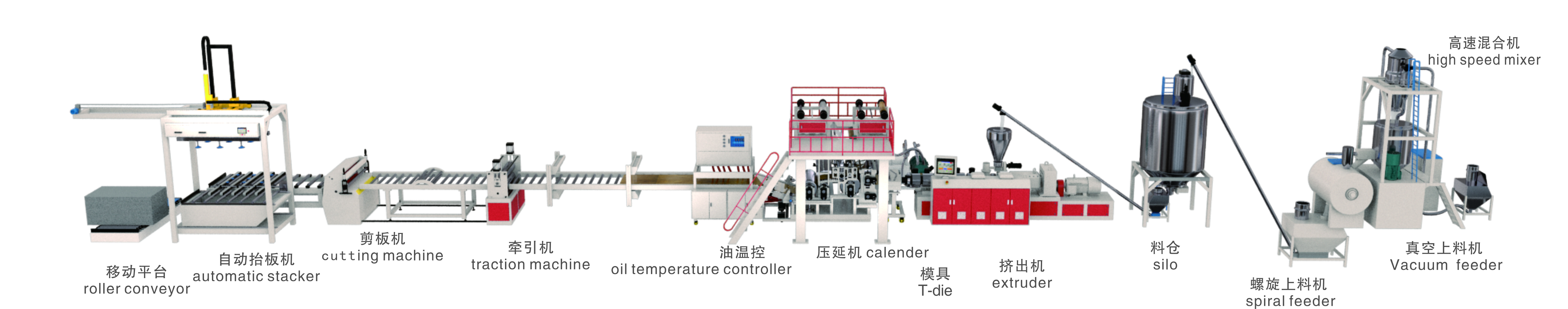

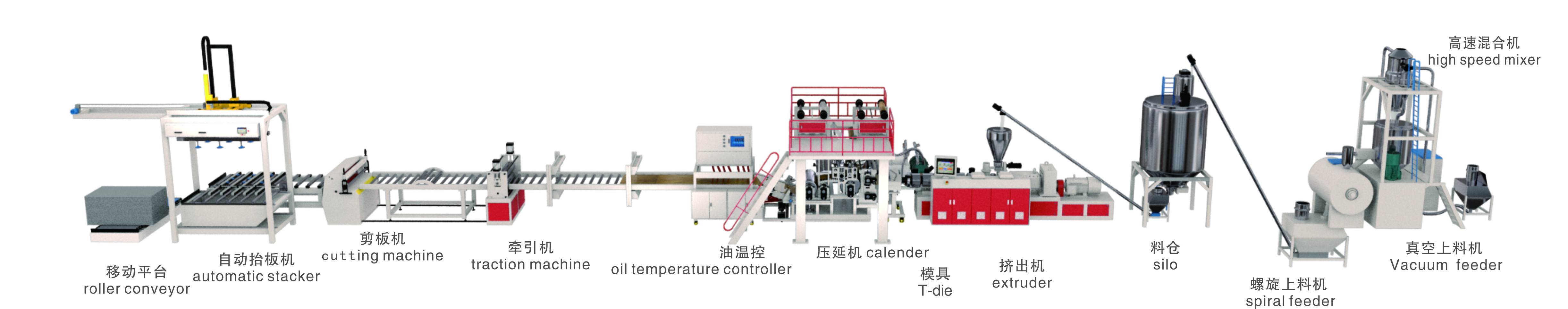

3.Production Flow

Material mixing → Extruder→ T-die → Calender → Traction machine →Cut-to-length →Stacking

4.Advantages of BOYU SPC Production Machine Line

1. More than 20 years experience on palstic machinery designing and manufacturing:

Leading industry level of mechanical and electric design

Various of machine lines for optional

Provide flooring production proposal of expert level

Proposal customized as per different market demand

High Stability, performance, safet

High efficiency smart equipment, less operator needed

2. EIR(High Quality&High Depth Embossing Performance)

The word leading level EIR technology

The unique one key embossing function is effectively short operation time

Deep embossing is helpful to achieve products differentiation

Constant tension system for film unwinding

Automatic deviation rectification system for film unwinding

3. Simple and Smart Electric Control System

PLC smart control system

Profinet connection method, to ensure fast data communication and achieve remote monitoring

Adopted famous internationla brand of electrical elements , much more decrease the faluts ratio.

Synchronous line speed control system

Anti-screw breakage, anti-bloacking die, automatic stacking control system

Automatic oil/water temperature control system

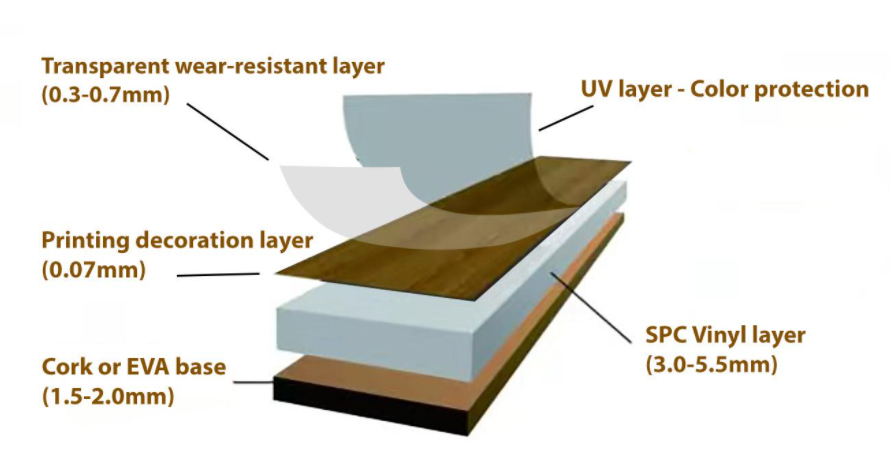

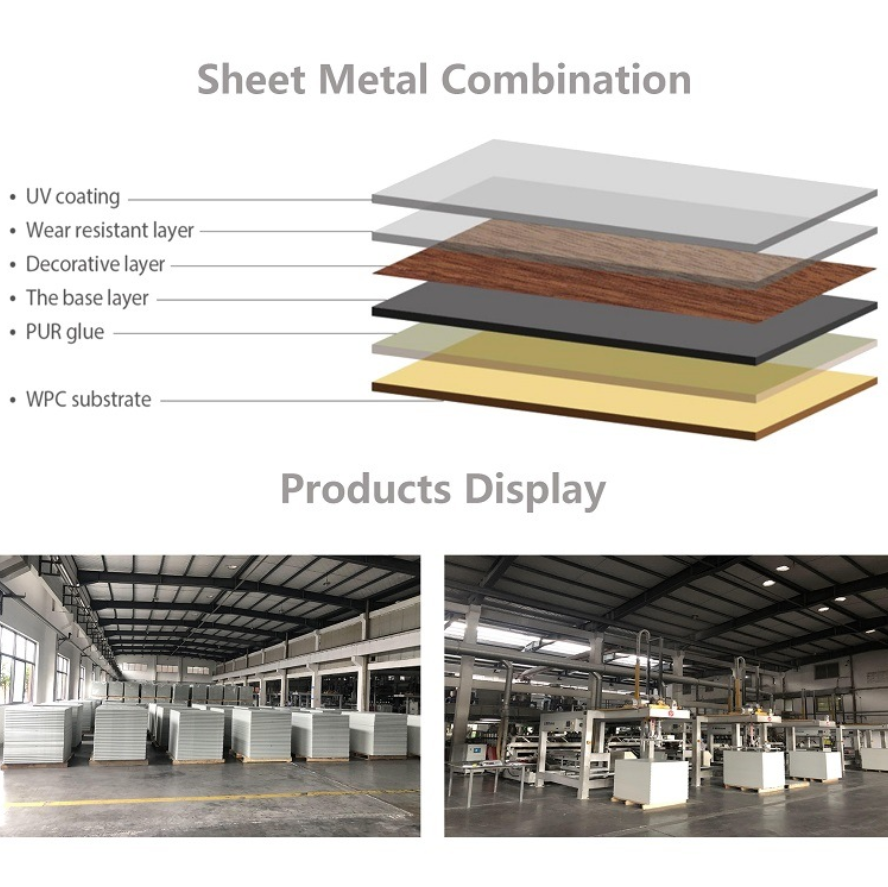

5.Finished board

The SPC floor is fire-proof, moisture-proof, antiskid,mildrew proof, tough and wear-resistant, with good decoration effect, convenient installation and simple maintenance. It is a high-quality environmental protection floor decoration material. The main raw material of SPC floor are PVC and Calcium powder, and these materials are non-toxic and environmental friendly renewable resources. The EIR system can ensure accurate synchronize of embrossing pattern and color film pattern, and make SPC floor feel as nature as wood floor.

6.EIR Patent

7.Our Services:

1. Pre-sale service:

To provide market research information and consultation;

To provide all kinds of convenience and market service;

To help customers make project planning and systematic analysis;

To maximize customer's satisfaction.

2. After-sale service:

To install products and test products for customers;

To provide the formulas and technologies of relevant products and the information of chemical materials manufacture;

To provide technical direction according to customers' requirements;

To provide technical training for clients' employees;

To be responsible for maintenance service, door-to-door service under necessary circumstance.

3. Technology Support

Provide different products for formula and material supplier.

Production technology&Technical guidance.

Technicians dispatching for Guidance and technology exchange.

8.Shipping

Send product request

Other supplier products

| SPC/WPC Flooring Production Line/ Plastic Extrusion Equipment | SPC floor base sheet is a new and high-tech environmental protection material. It is the product of the mixing pvc resin and processing agent going... | |

| Plastic PVC Imitation Marble Sheet Extrusion Production Line|Extruder|Extrusion Line | PVC Imitation Marble Profile Extrusion Production LineI. Design parameters No. Items Data 01 Operation Conditions 380V/3 phases/50Hz, DC24V. ... | |

| PVC Foam Board Extrusion Line/Plastic Extrusion Machine/PVC Board Production Machine | WPC/PVC Foam Flooring Base Sheet is a new and high-tech environmental protection material. It is the product of the mixing pvc resin and processing... | |

| SPC/WPC/PVC Sheet Production Line/Poly-Vinyl Chloride Flooring Machine | Stone Plastic Composite SPC Flooring ExtruderSPC floor base sheet is a new and high-tech environmental protection material. It is the product of th... | |

| WPC Foam Floor Extrusion Production Line/ Wood Plastic Composite Flooring Equipment | WPC/PVC Foam Flooring Base Sheet is a new and high-tech environmental protection material. It is the product of the mixing pvc resin and processing... |

Same products

| WPC Terrace panel extrusion line | Seller: Qingdao Trusty Plastic Machinery Co.,Ltd | Wood-polymer composite (WPC), unlike wood, has higher resistance to aggressive environments and v... | |

| High Efficiency Series of Screw Extruder | Seller: Shandong Decao Machinery & Equipment Co., Ltd | Extruded Snacks Making Machineis a complex system that integrates multiple key equipment and proc... | |

| Benchtop Extruder | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | Key Features of Benchtop Extruder() Precision Control: Benchtop Extruder is designed to provide m... | |

| SHJ Series Twin Screw Extruder | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The SHJ Series Twin Screw Extruder() represents a remarkable evolutionary step in the field of ex... | |

| Underwater Pelletizer | Seller: Nanjing Chuanqi intelligent Equipment Co., Ltd. | The Underwater Pelletizer(), a technological marvel in the polymer processing sector, has redefin... |