Overmolding & 2k Molding

The same type of material of different colors is usually used for two-color injection molding(or 2k molding)so that the bonding strength of the first color and the second color plastic is the best, but due to the functional requirements of the product, the performance difference of the two materials actually used may be very big, if the elastomer is injected into the surface of a rigid material, the most difficult thing to solve during 2k moulding process is the delamination and shedding of the bonding surface of the two materials.

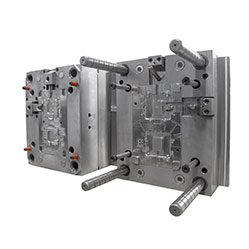

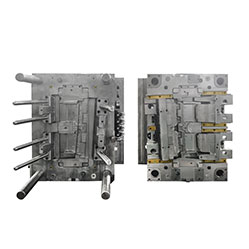

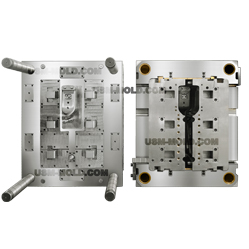

OVER-MOULDED 2K MOLDSFOR SALE

Water Proof Plastic Enclosure Mold

The product will be made by two times, which will inject the second piece after finishing the first piece in the other mold and different injection machine, normally will be no specific request for 2 different pieces injection time, injection machine.

Drip Tip Mold

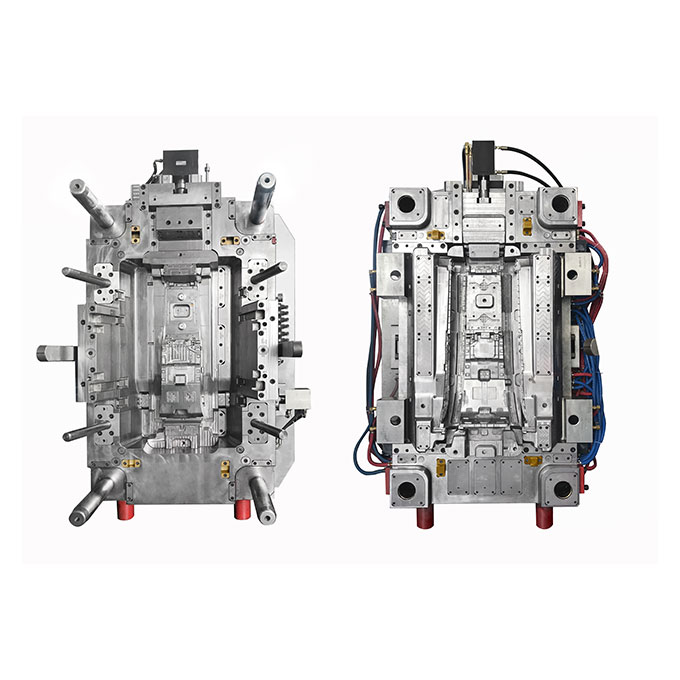

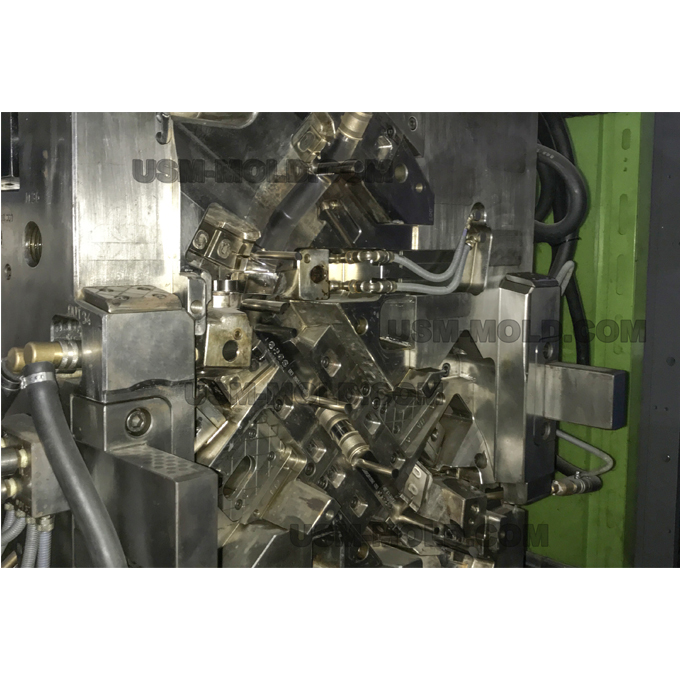

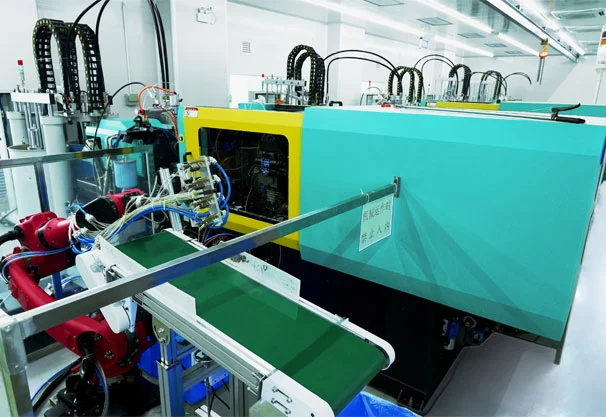

The two-color molding will be made in one same injection machine at the same time by 2 times injection, with 2 injection barrels and 2 different injection gates by 2 different molds, but the product will be picked up one time, it will request 2 molds in one specific 2k injection machine to finish final injection.

2K Mold

This mold will be put with a movable core on gate position of the core side, the movable core is pushed to the rising position when injecting the first-color material, and the first color part is solidified, After that, the movable core return back through the action of the hydraulic device, at this time, another barrel injects the second color material into the space left by the retreat of the core, the mold is opened and the part is taken out after finishing one injection after it's solid.

Material Selection For 2K Plastic Injection Moulding

In addition to meeting the requirements of product function and appearance in the material selection of two-color products, whether the adhesion between raw materials can be solved well will be related to the success of two-color products in 2k moulding process is also the difficulty of 2k insert moldingtechnology.

The following four points should also be considered in the selection of materials for two-color injection molded products:

2K Molding Design Guide

Structural design is the most important part of 2k molding product design, the structure design of the product should not only consider the function of the product but also consider whether it meets the processing conditions and the complexity of the processing mold, in the design of two-color injection products, in addition to the issues to be considered for ordinary injection products, the following aspects should also be considered:

- Product structure shape design: in order to increase the 2k moulding product's fusion strength, the measure in the product structure design is to increase the contact area of the two parts. For example, if possible, the contact area of the two parts can be enlarged through the non-joining surface, and concave and convex grooves can be designed around the small cavity products (which can be generated by forced demolding, and the depth can reach 2mm).

As professional 2k molding manufacturers, we can offer kinds of related products for sale, anything you need, please contact us.

There are many custom plastic products manufacturersin China, but we are one of the best choices for you.

Send product request

Other supplier products

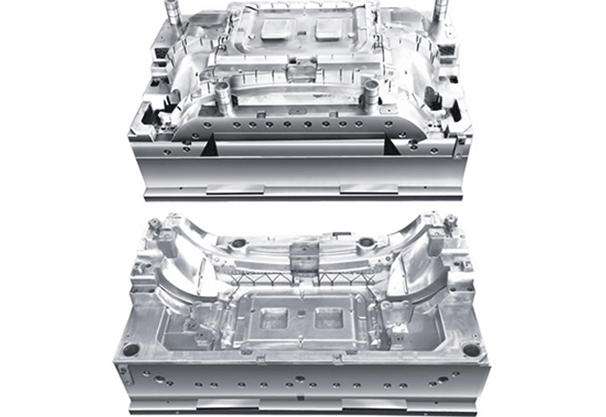

| Automotive Mold | Large drop of automotive mold top and bottom; The automotive mold technology is complicated; The injection system is many and complicated; The mold... | |

| Auto Parts Mould | Injection Moulding Automotive Partsfeatures: There are many undercuts on product inside and outside, and the undercut area is big too, the... | |

| Medical Mold Injection Product | Medical Moulded Products Different requirements will have different mold steel and products material, USM will choose the mold steel material acco... | |

| Automotive Water Intake Manifold Mould | Automotive Water Intake Manifold Injecting gas through the nozzle is a typical method used in rod-shaped products, because this method does not re... | |

| Gas & Water Assisted Injection Mold | Gas & Water assisted injection molding Since the thermal conductivity and heat capacity of water are much bigger than nitrogen, so the injecti... |

Same products

| Silicone Rubber Injection Molding | Seller: Packson Mold Co.,Ltd | Packson's state-of-the-art facilities consist of a 1000㎡ certified clean room, which is equipped ... | |

| Prototype Injection Mould | Seller: Packson Mold Co.,Ltd | Packsonmold is a company that provides high-quality prototype services, including 3D printing, CN... | |

| Precision Injection Molding | Seller: Packson Mold Co.,Ltd | At Packson, we specialize in manufacturing custom precision mold partsand machined parts that mee... | |

| Overmolding Injection Molding | Seller: Packson Mold Co.,Ltd | Overmoldingmold is made of overmolding injection molding processwhich is a special injection mold... | |

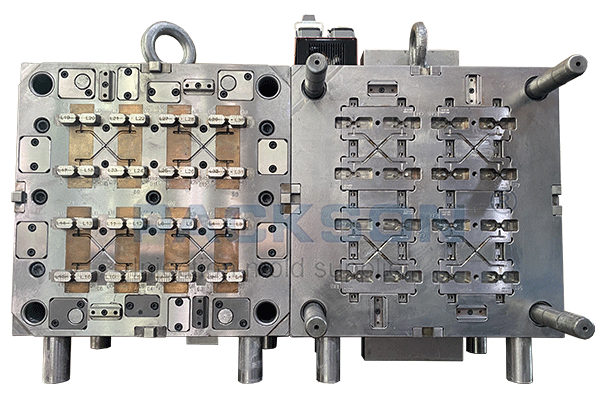

| Multi-cavities Injection Molding | Seller: Packson Mold Co.,Ltd | Multi cavity mouldis an injection mold that has more than one cavity. The shape of each cavity is... |