Rod Tube Rotary Eddy Current Flaw Detector ET 15/40/65/90

Rod Tube Rotary Eddy Current Flaw Detector ET 15406590 Brief

Rod Tube Rotary Eddy Current Flaw Detector ET 15406590 Performance

Testing Standard:GB/T 11260-2008 round steel eddy current testing method, GB/T 7735-2004 steel tube eddy

Current testing method

Longitudinal artificial injury:0.10(depth)×0.10(width)×20mm(length)

Tube end conditions:

1) deburring at both ends, cross-sectional deformation equal to less than the diameter tolerance

2) Straightness tolerance: tangential direction up to 1.5mm/m and not exceeding the total length of the workpiece

3) Diameter tolerance and ovality: reference DIN standard

Rotating flaw detection system technical performance index

(1)The non destructive testing machine can accurately, reliably and stably record, alarm and mark the defects of the finished steel pipe.

(2)Detection speed:<60m/min

(3)Detection of end -end tail dead zone:

50mm signal to noise ratio: ≥ 10dB

Sample miss rate: 0%

Sample stick false positive rate: ≤2%

Stability: ≤1dB after 2 hours

Marking accuracy: ±30mm

Poor circumferential sensitivity: ≤1dB

(4)100% coverage detection, the instrument sets the upper and lower boundaries, exceeding or lower than the automatic alarm record;

(5)Flaw detection machine operation mode: fully automatic, complete electronic control system, portable eddy current tester, auxiliary control.

The high-speed rotation detection system has the following important features:

l Precision positioning and drive mechanism technology in tube rod inspection;

l Adopting the rotation of the probe and straight forward of the tube rod, the speed is fast, the noise is small, reliable, and the sensitivity is high;

l Multi-channel noise suppression technology;

l Detecting steel rods of different diameters without changing the probe, can continuously and accurately adjust the gap between the steel rod and the eddy current probe;

l The signal adopts high-speed DSP signal processing mode, and each channel signal is processed independently, and the transmitted signal-to-noise ratio is high;

l Wireless transmission technology, no sparks:

l Has a high service life and a small longitude detection blind zone;

l Do not replace the probe rotation detection technology;

l The equipment can operate stably all year-round.

We are one of the leading non destructive testing equipment manufacturers, RFQ today.

Send product request

Other supplier products

| GSET-551 Steel Wire Eddy Current Flaw Detector 1024 | GSET-551 Steel Wire Eddy Current Flaw Detector Brief Using the eddy current signal processing method and high-performance DSP algorithm, the NDT wi... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current testing of welds is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossle... | |

| Eddy Current Testing for Auto Parts | NDT Application in Automotive Industry: Eddy current hardness testingtechnology has been widely used in the detection of metal components in the... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current weld testing is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless. ... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current weld testingis the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless. A... |

Same products

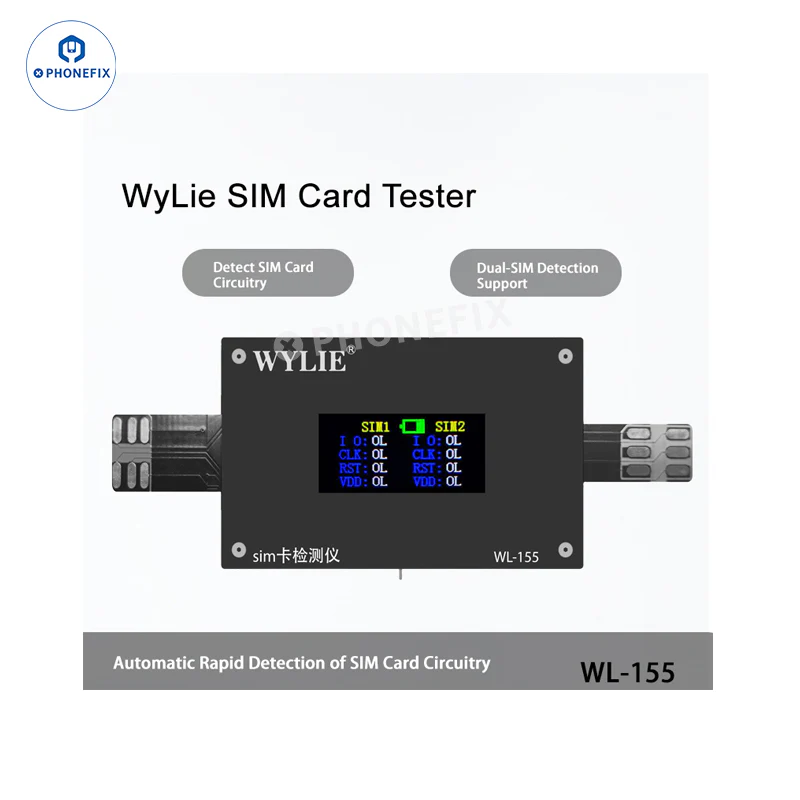

| WYLIE WL-155 SIM Card Tester for iPhone 14-17 Pro Max & Android | Seller: China PHONEFIX Technology Co., Ltd | WYLIE WL-155 SIM Card Tester is used to detect SIM card circuits and supports dual-SIM detection ... | |

| HCV1500 High-precision Voltage Sensor | Seller: Shenzhen Hangzhi Precision Electronics Co., Ltd | HCV1500 high-precision voltage sensor is a voltage sensor that can measure DC, AC, pulse and vari... | |

| Xenon Test Chamber | Seller: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | Seller: Qinsun Instruments Co., LTD | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... | |

| Safety Helmet Flammability Tester | Seller: Qinsun Instruments Co., LTD | Product Introduction: Safety hat flame retardant performance tester for safety hat flame retarda... |