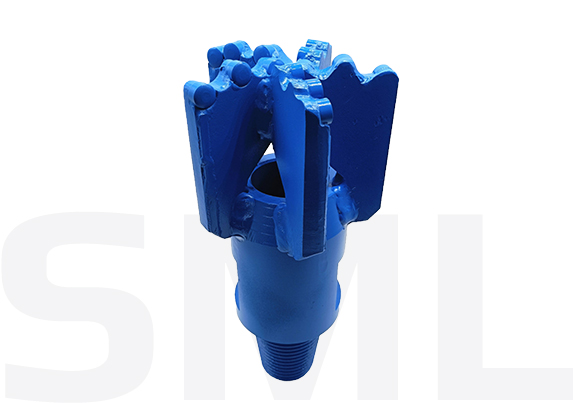

PDC DRAG BIT

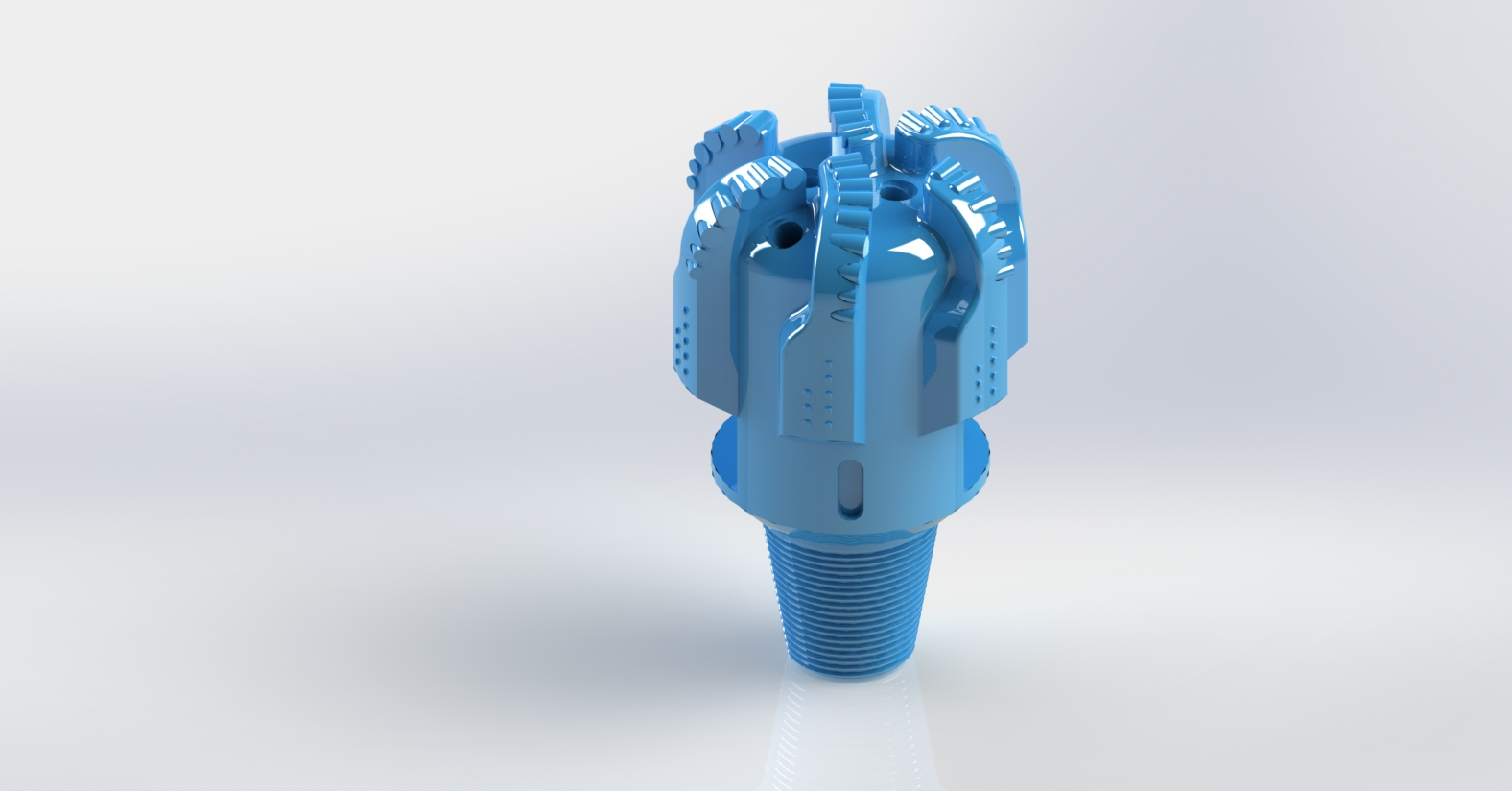

The PDC drilling drag bitis a composite of four main components: the bit body, the drag blade, the water diverter cap, and the nozzle. Forged from medium carbon steel, the bit body integrates the drag blade and water diverter cap, anchoring at the upper end to the drill column through threaded fasteners. The drag blade, alternatively referred to as the blade wing, stands as the central operational part of the drag bit.

Ideal for traversing soft soils and pliable, fragile formations like mudstone, muddy sandstone, and shale, PDC Drag bitare a staple in drilling applications. As one of PDC drill bits manufacturers, Top Tool's Drag bits are typically tailor-made, drawing extensively on client blueprints and dimensional stipulations.

Features Of PDC Drag Bit

PDC Drag Bits are optimized for soft and cohesive formations. They cut rock akin to a knife through soft metal. In pliable terrains, the blade penetrates under drilling pressure, with the rock flowing plastically due to torsional forces, facilitating a layered extraction at the well's base.

Features Of PDC Drag Bit

Advantages Of SML PDC Drag Bit

Tailored Design: Our senior designers craft designs tailored to client specifications, ensuring complete satisfaction.

Enhanced Water Hole Design: The oversized water hole feature improves water intake and slag discharge, amplifying drilling efficiency.

Balanced Wear Technology: PDC Drag Bit employs an equal cutting volume principle for tooth placement, ensuring even wear and maximizing bit lifespan.

Advanced Hydraulic Structure: Our PDC Drag Bit integrates a blade wing hydraulic design with water eye and flow channels, promoting timely bit cleaning. This avoids repeated rock chip breakage, maximizing cutting efficiency.

State-of-the-Art Manufacturing: We employ pioneering medium-frequency induction low-temperature brazing and PDC drill bit mold forming techniques to guarantee superior drill bit quality.

Broad Formation Compatibility: The Drag Bit is versatile, suitable for drilling in soft to medium-hard (grades 2-6.5) non-abrasive formations.

If you are looking for a reliable drill bit factory, don't hesitate to contact us!

Send product request

Other supplier products

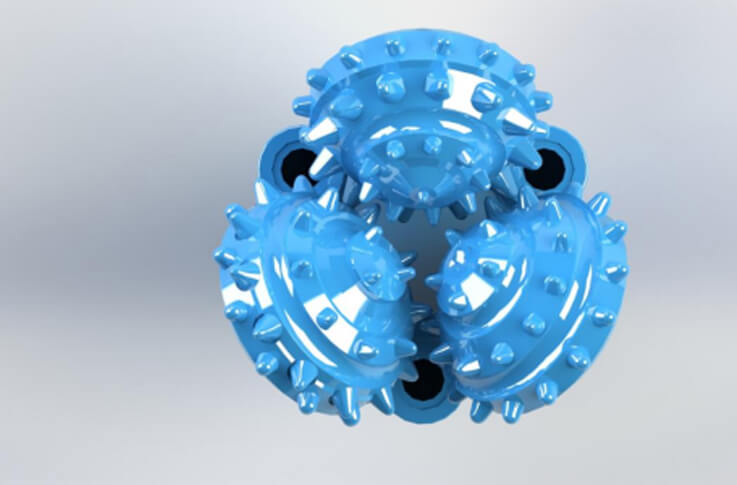

| TCI Tricone Bit | Under the effect of the WOB and the twist of the drill string, the teeth of the tci tricone drill bitsare crushed and eaten into the rock, and at t... | |

| Matrix PDC Drill Bit | PDC matrix bitis a kind of cutting bit that weld the diamond composite piece on the drill head body by brazing. PDC matrix bitis sintered with tung... | |

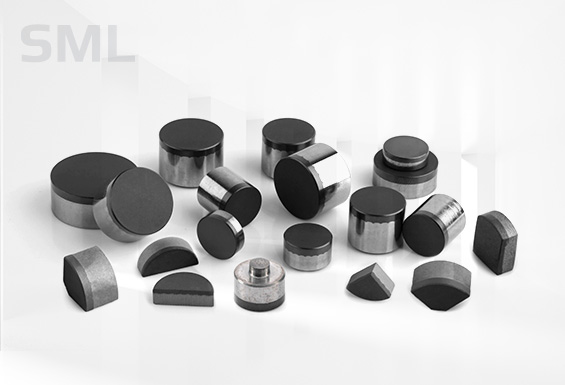

| PDC CUTTER | The artificial pcd insert, crafted from polycrystalline diamond cuttersintegrated with a carbide matrix, combines diamond's inherent hardness and t... | |

| Hybrid Drill Bit | The hybrid bituses a mixed cutting method. The tricone bit is to be broken by impact on the stratum, and then the PDC blade is cut to effectively p... | |

| STEEL TOOTH BIT | The Steel Tooth Bit teeth are crafted from milled tooth wheel blanks, primarily featuring wedge-type designs. A balanced tooth structure promotes r... |

Same products

| PDC DRAG BIT | Seller: WUHAN SML TOOLS LIMITED | The PDC drilling drag bitis a composite of four main components: the bit body, the drag blade, th... | |

| biochemical optical narrow bandpass filter | Seller: Beijing BoDian Optical Technology Co., Ltd | 1.Substrate:BK7 Glass, 2.Process:IAD Hard Coating, 3.Transmittance: better than 85%, 4.Blocking r... |